manually extrude driver 2 on DWC?

-

hey,

how can I manually extrude with extruder 2 in the DWC?

When I retract or extrude it´s always Driver 0.thanks a lot to all!

-

@barbarossa-cologne

you will need to configure a second tool and assign the extruder 2 to that tool.

Then select the second tool

-

@Veti thanks

maybe there is a link to read how to do it?

I´m confused because in ´´status´´ are 3 extruder..

-

Post your config please

-

Click on the Tool 0 in the the ui

-

@jay_s_uk

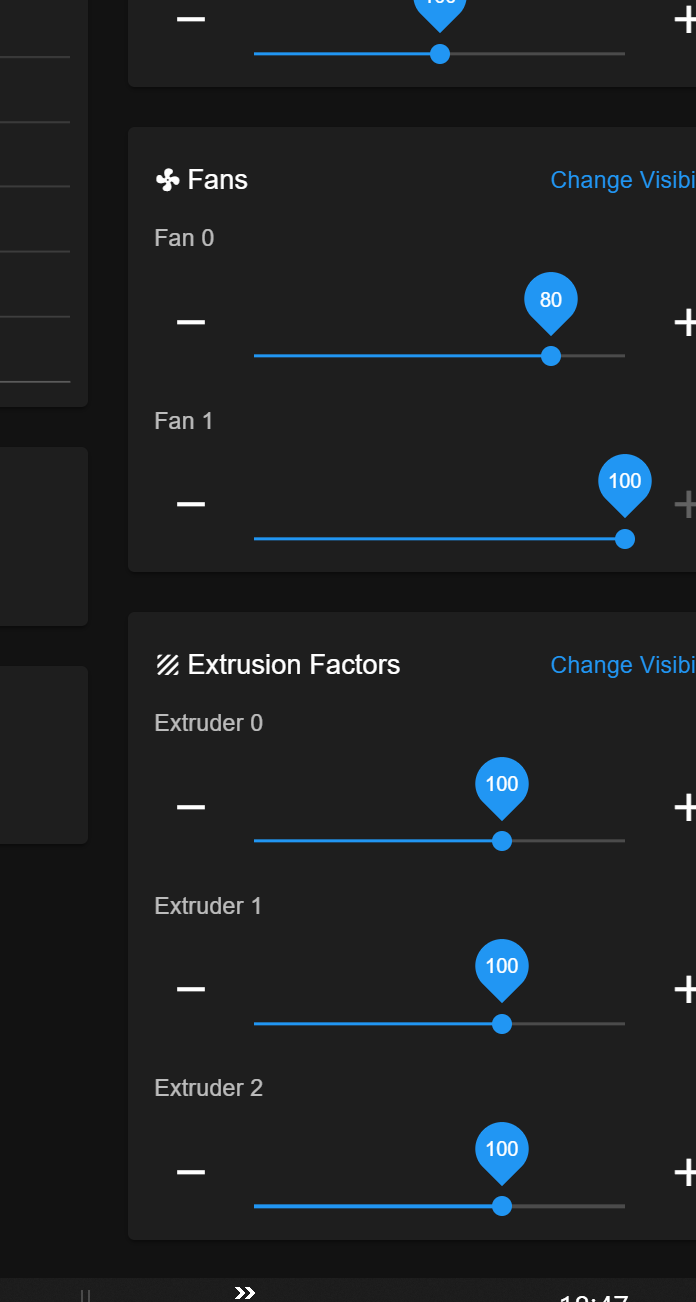

sry; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.3 on Tue Jun 23 2020 22:36:44 GMT+0200 (Mitteleuropäische Sommerzeit) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S1 ; physical drive 0.3 goes forwards M569 P0.4 S1 ; physical drive 0.4 goes forwards M569 P0.5 S1 ; physical drive 0.5 goes forwards M569 P1.0 S0 ; physical drive 1.0 goes forwards M569 P1.1 S1 ; physical drive 1.1 goes forwards M569 P1.2 S1 ; physical drive 1.2 goes forwards M584 X0.0 Y0.1 Z0.2:0.3:0.4:0.5 E1.0:1.1:1.2 ; set drive mapping M350 X16 Y16 Z16 E16:16:16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z1600.00 E409:409:409 ; set steps per mm ; set steps per mm M566 X900.00 Y900.00 Z12.00 E120.00:120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z40.00 E250.00:250.00:250.00 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z3000 E1000:1000:1000 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X700 Y700 Z800 S0 ; set axis maxima ; Endstops M574 X2 S1 P"!io3.in" ; configure active-high endstop for high end on X via pin !io3.in M574 Y2 S1 P"!io0.in" ; configure active-high endstop for high end on Y via pin !io0.in ; Z-Probe M558 P9 C"io4.in" H10 F200 T1800 ; set Z probe type to bltouch and the dive height + speeds M950 S0 C"io4.out" ; create servo pin 0 for BLTouch G31 P25 X-20 Y-20 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X10:600 Y10:600 S200 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H1 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S90 ; set temperature limit for heater 0 to 90C M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"out8" Q500 ; create fan 0 on pin out3 and set its frequency M106 P0 S0.8 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out7" Q500 ; create fan 1 on pin out7 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off M950 F2 C"out8" Q500 ; create fan 2 on pin out8 and set its frequency M106 P2 S1 H T45 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M671 X-19.5:99.5:99.5:-19.5 Y110:110:540:540 S2.5 ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power -

@Veti

ui?

what is it?

sry I have a massiv machine but I´m still bloody in the duet-3dprint slang

-

your printer only has 1 tool defined

what do you want to do with the second e motor?

-

@barbarossa-cologne said in manually extrude driver 2 on DWC?:

ui?

user interface.

can you give use some more info. did you create the config yourself?

what kind of printer is it? -

@Veti sure

yes user interface haha sryI made most of the g.code with the configuration tool and added some lines because of the 4 z axis motors.

It´s a custom made printer. At the moment I want to install the hemera direct kit... I think that I destroyed motor driver 0 on the expansion board. That is the reason I wanna extrude with the second extruder/motor driver....

Also when I started printing with extruder 2 / driver 1 , it was extruding on driver 0. -

@barbarossa-cologne said in manually extrude driver 2 on DWC?:

M563 P0 D0 H1 F0 ; define tool 0

change this to

M563 P0 D1 H1 F0 ; define tool 0The D parameter selects which driver to use for tool 0