Help on fixing bed mesh on Delta

-

@MikeS said in Help on fixing bed mesh on Delta:

@fcwilt ok i could try tomorrow to spray paint it but the fact that the "lines" are aligned with Y axis make me think of a mechanical problem, but can't get what. I don't know delta kinematics so well to see the problem there...

Understood but at the very least you will verify that it is NOT a problem with the Mini IR detecting the correct surface.

My first three printers were delta's and I had a difficult time getting them to work as well as I wanted. Then I got my first Cartesian. It worked so much better with so much less effort that I disposed of the delta's and never looked back.

Yet some folks get them working fine. Go figure.

Frederick

-

@fcwilt i think that they don't get them to work "fine" but usable...but i understand them, they are like me: never surrender!

Delta are really pleasant to look at and really neat as aesthetic but i would never recommend one to someone that is not skilled in 3d printing! There is so much to learn and i have lose count years ago on the hours i've spent with this printer. I still hope that with a duet better hardware and firmware i'll manage to get it printing consistently. Tomorrow i'm going to recheck all the joints and mechanics in general...still sure that the problem is there, i hope to get at least the bed at around +-0.1mm at the end. -

just to rule out the ir as a problem you could try this probe

https://de.aliexpress.com/item/32968709878.html

its very check and i use it on my delta because i have no offset using it. -

@Veti I think it won't fit my layer fan mount. I'll get it anyway because it's cheap and could be useful anyway!

However i've a little update. This morning i was checking carriages and arm mount and i felt that there was a little play between u joints and carriages. After disassembly i found that some custom adpater i've made have become a little loose (i think we are talking about some cents of mm). Here are some photos for reference:

Now i've taken all apart, cleaned and tried to fill this little gap with threadlocker. It already feels stiffer but i now must wait 2/3 hours to let it cure. I'll post back with the results of next G32/G29 and see if that fixes something.

-

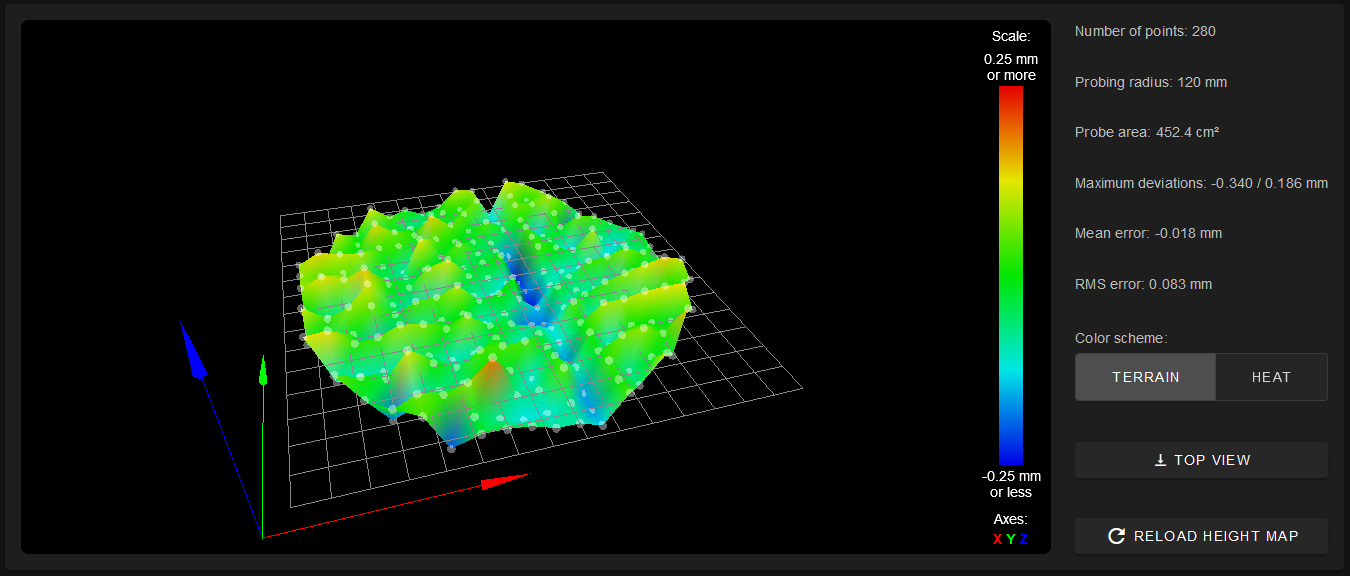

So after the fix:

M666 Endstop adjustments X0.45 Y0.00 Z-0.45, tilt X0.00% Y-0.39% M665 Diagonals 269.000:269.000:269.000, delta radius 129.470, homed height 349.814, bed radius 120.0, X -0.431°, Y 0.121°, Z 0.000°

I think to know why there is this blue line along Y axis and will try to fix it. However is it possible to change the probing sequence of G29? I would like to try to probe by column and not by row starting from far left on build plate and going up/down instead of left right, only to see if this lead to more even results among the bed.

-

@Veti didn't had time to get progress on bed calibration but i have exported my E3D V6 mount in STEP. I hope it can be useful to you or someone else

E3D mount V2.step

The mount is split in 2 part with a little tolerance between so it can be mounted/unmounted without removing the extruder. It's designed to use screw and nuts but you can also use cable ties for testing. -

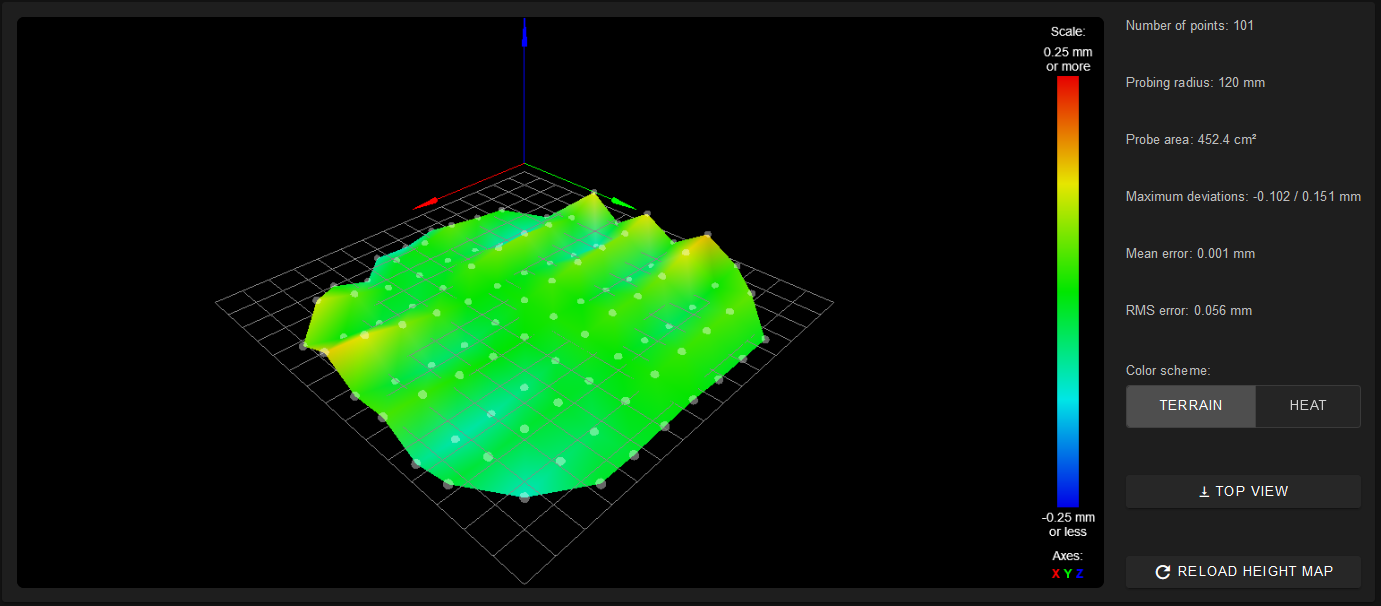

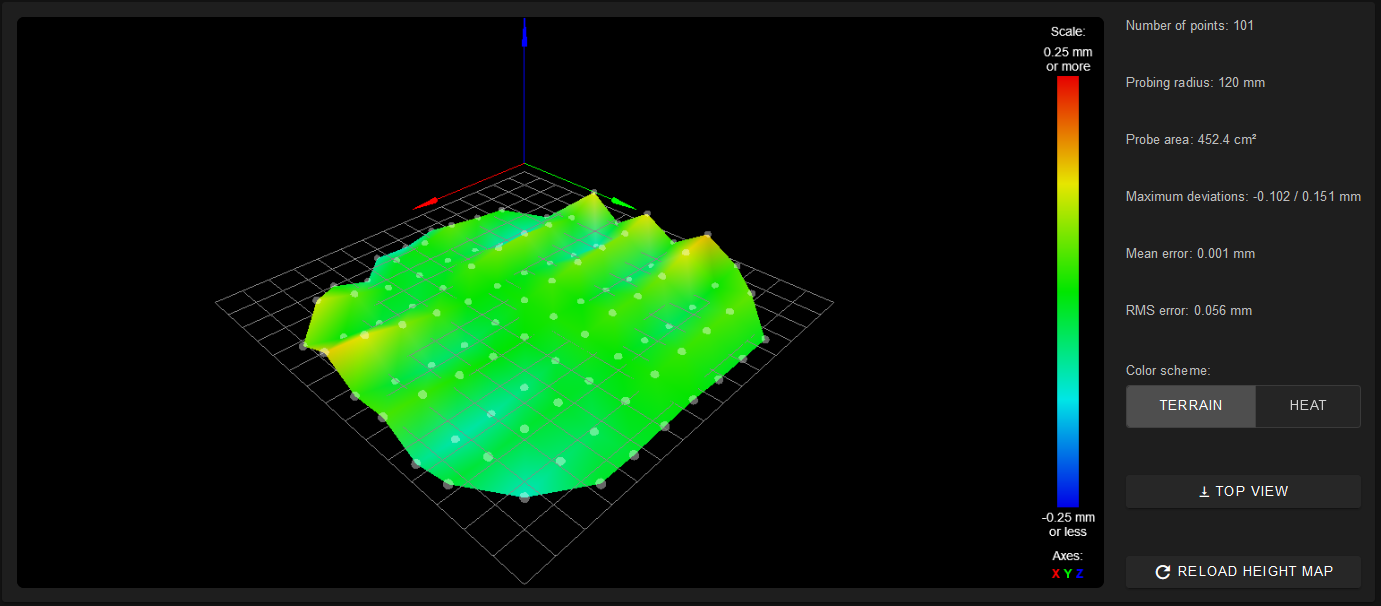

@fcwilt just a quick update. Tried to black paint with standard spray paint the bed and probe can reach it also when it is put on the bottom side. Today high temp black paint has been delivered by amazon and now i've cleaned the glass from bed and sprayed the new one. Now i'm curing it on the heated bed at 120°C then i will do some test. Here's a bed map from the bed painted with standard paint:

Also have printed and fixed some corners to help the mechanics to be more rigid. -

@MikeS said in Help on fixing bed mesh on Delta:

@fcwilt just a quick update. Tried to black paint with standard spray paint the bed and probe can reach it also when it is put on the bottom side. Today high temp black paint has been delivered by amazon and now i've cleaned the glass from bed and sprayed the new one. Now i'm curing it on the heated bed at 120°C then i will do some test. Here's a bed map from the bed painted with standard paint:

Also have printed and fixed some corners to help the mechanics to be more rigid.That looks better but there are still those peaks.

Was that done with the paint on the top?

Is this a fairly consistent result?

Frederick

-

@fcwilt nope this was done with paint on the bottom of the plate so it should be nearly perfect considered that the glass is really flat (tested with rectified rails along the glass). I think the peaks are given by the structure of my delta that is not so rigid (Rostock Max V2 by seemecnc from 2014) it's made of "compressed carboard" also called melamine wood. Obviously it is not rigid as it would be if built with some aluminium.

-

Hi,

For diagnostic purposes you should try it with the paint on top to be sure you are not getting readings from reflections.

Frederick

-

Here's a general guide for delta printers:

-

If the height map shows random peaks and dips, that is caused by inconsistent trigger height of the Z probe. The IR sensor suffers from this when the bed surface is reflective to IR, for example glass or PEI. Putting a matt black surface under the bed improves the IR sensor in this respect, but it's still not as good as some other types of probe e.g. Smart Effector.

-

If the height map shows ridges at one end of the X direction turning into valleys at the other, alternating with probing direction, this indicates backlash in either the carriages or the joints. Lubricating the joints and carriages may help. If the carriages are the source, higher belt tension or higher motor current may also help.

Yout latest height map is a lot better than earlier ones. It still shows effect #2 to some extent, but it looks as though you have eliminated #1.

-