Hi all,

i'm facing some issues in previewing own made g-code for a cnc foam cutting machine i'm making.

Machine is made of 4 axis named X,Y,U,V. X is right X carriage, Y is right Y carriage, U is X left carriage and V is left Y carriage. Between the carriage there is a hotwire that i use for cutting foam.

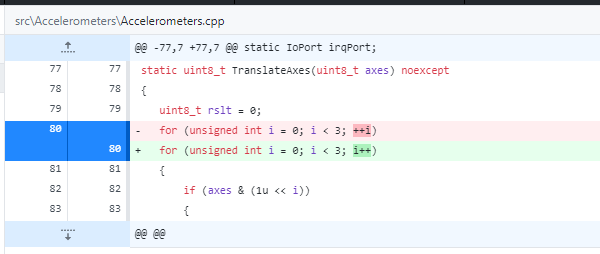

I've written a small Autocad macro for outputting custom G-Code from a closed polyline to allow machine control. Since now i've used https://ncviewer.com/ for checking the output g-code and bugfixing the macro.

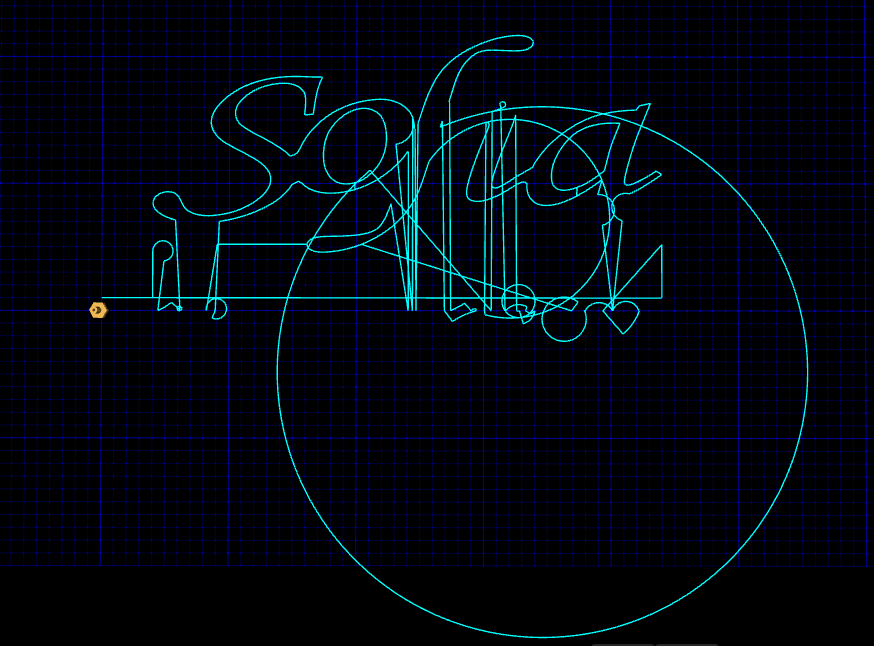

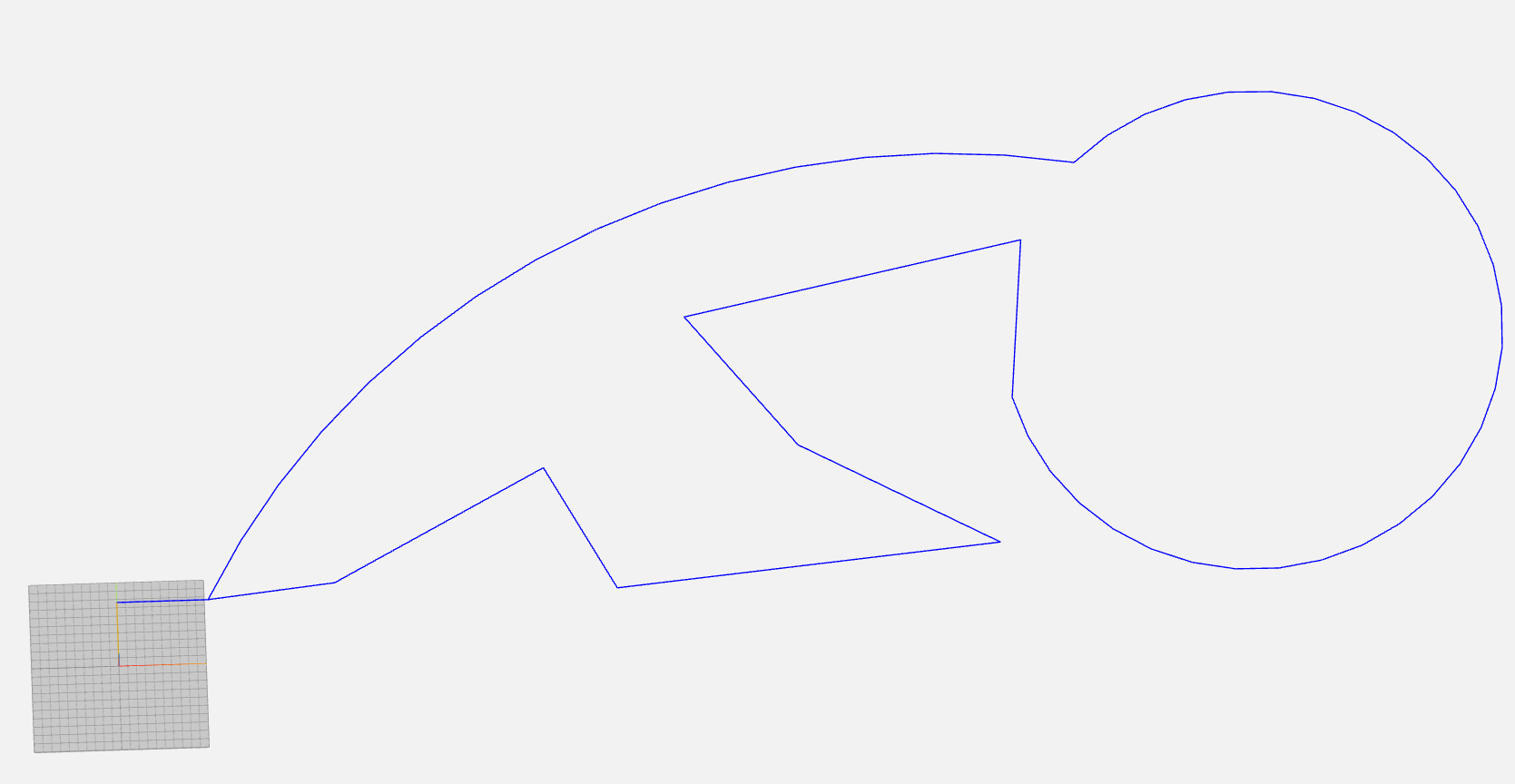

Now i've tried uploading a sample code to DWC and preview it. The result is different from what i would have expected and from what the ncviewer is showing. Anyone could replicate it? i'm doing something wrong? X Y U V and I,J values seems to be correct checking them against cad drawing.

PS: i didn't run the code on the machine so i still don't now if this is only related to the preview or to the duet motion too.

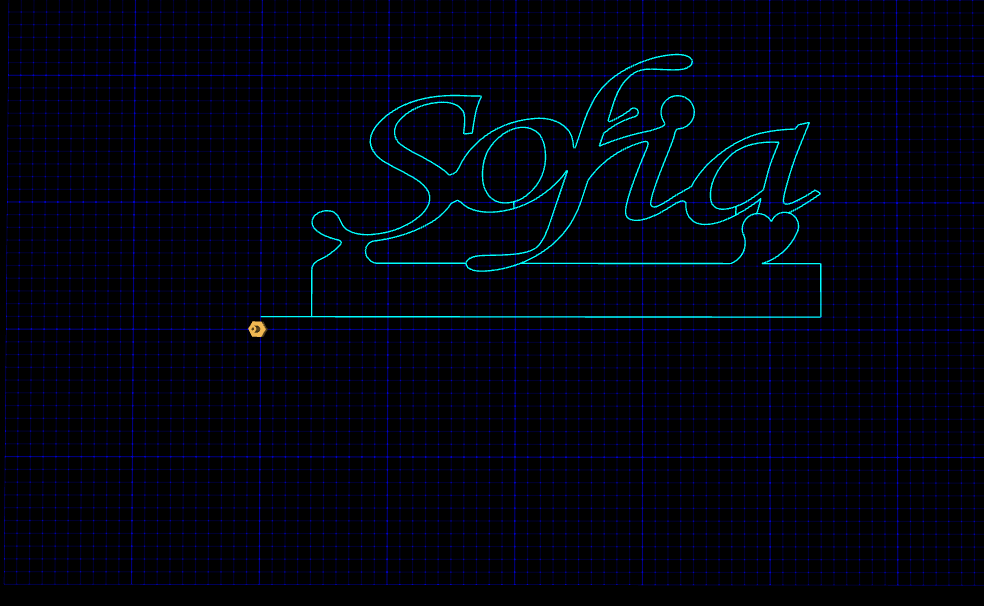

I attach here the result and the gcode:

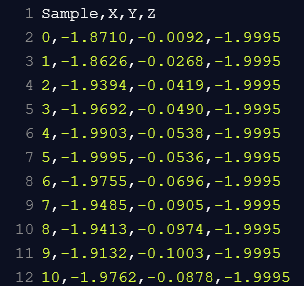

Gcode:

G0 Y7.67669351816836 V7.67669351816836

G1 X10.460086722869 Y7.67669351816836 U10.460086722869 V7.67669351816836

G2 X111.312729233058 Y56.8157257089499 U111.312729233058 V56.8157257089499 I83.5083390409037 J-43.3278104191889

G2 X103.316129299667 Y28.9066637370007 U103.316129299667 V28.9066637370007 I19.773679663431 J-20.7657599308204

G1 X104.906216011594 Y47.7466616126872 U104.906216011594 V47.7466616126872

G1 X66.0782304671486 Y39.7601877983511 U66.0782304671486 V39.7601877983511

G1 X78.6102154332631 Y24.0166143731538 U78.6102154332631 V24.0166143731538

G1 X101.406493263683 Y11.6125868744677 U101.406493263683 V11.6125868744677

G1 X57.365517020264 Y7.55742399224854 U57.365517020264 V7.55742399224854

G1 X49.3689168105043 Y22.2275719838839 U49.3689168105043 V22.2275719838839

G1 X25.0210598390317 Y9.22719695550413 U25.0210598390317 V9.22719695550413

G1 X10.460086722869 Y7.67669351816836 U10.460086722869 V7.67669351816836

G1 X0 U0

G0 Y0 V0

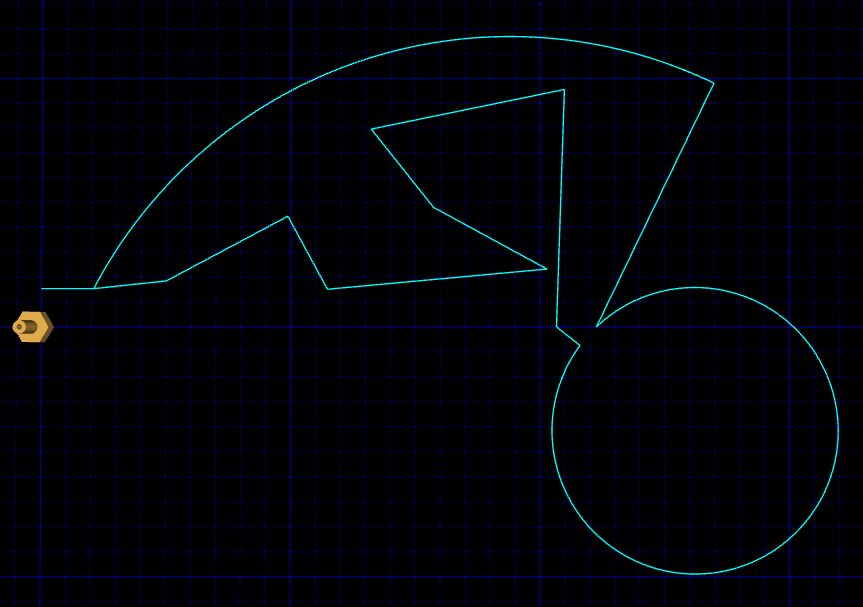

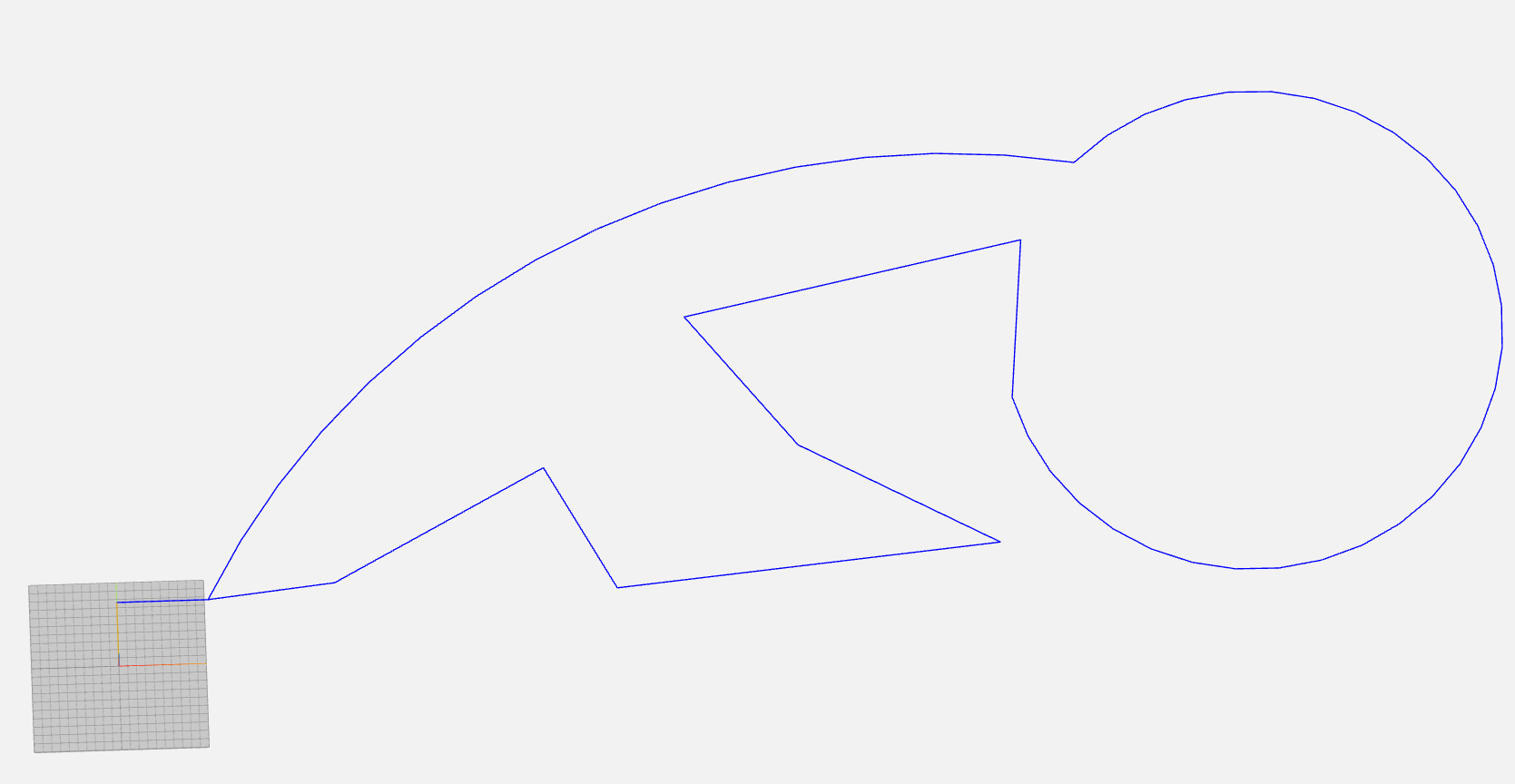

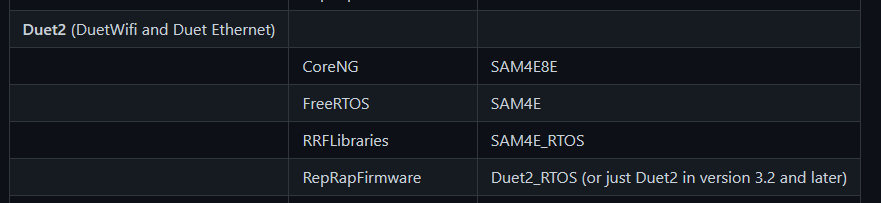

NCViewer preview:

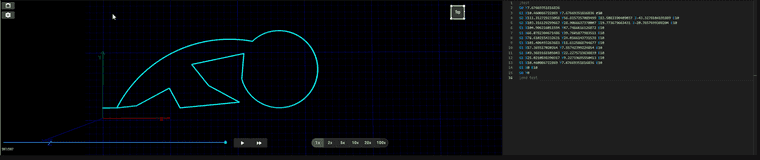

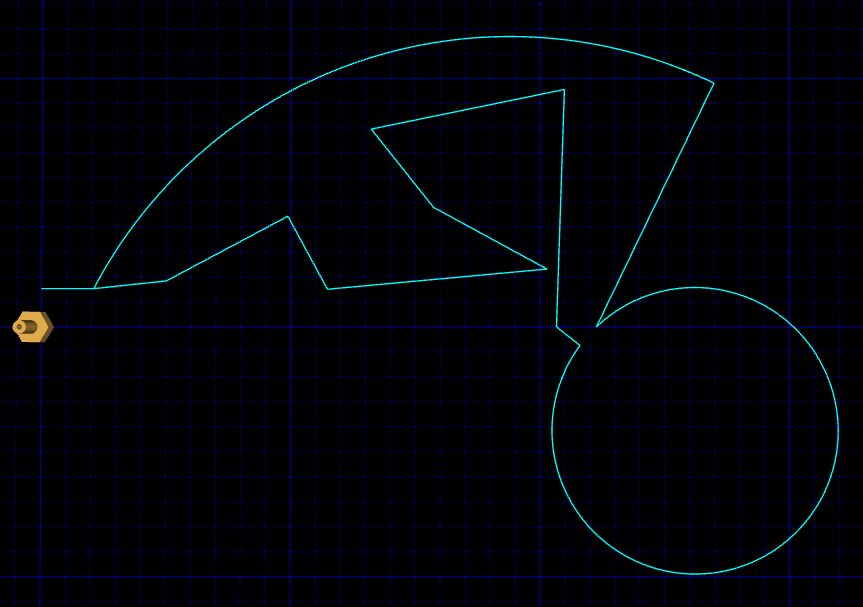

DWC Preview: