Do Linear Rails Perform Well Under Cantilever Loads?

-

So recently on my d-bot, I've ditched the v rollers on the z axis in favor of linear rails. Now my main concern is that linear rails arent designed for cantilever forces right? hence the name linear. Im wondering if it would be better in the long run to install 2 more rails on the front side, so that there are 4 rails instead of 2, eliminating the cantilever design in favor for a voron2 style system with rails on all 4 corners.

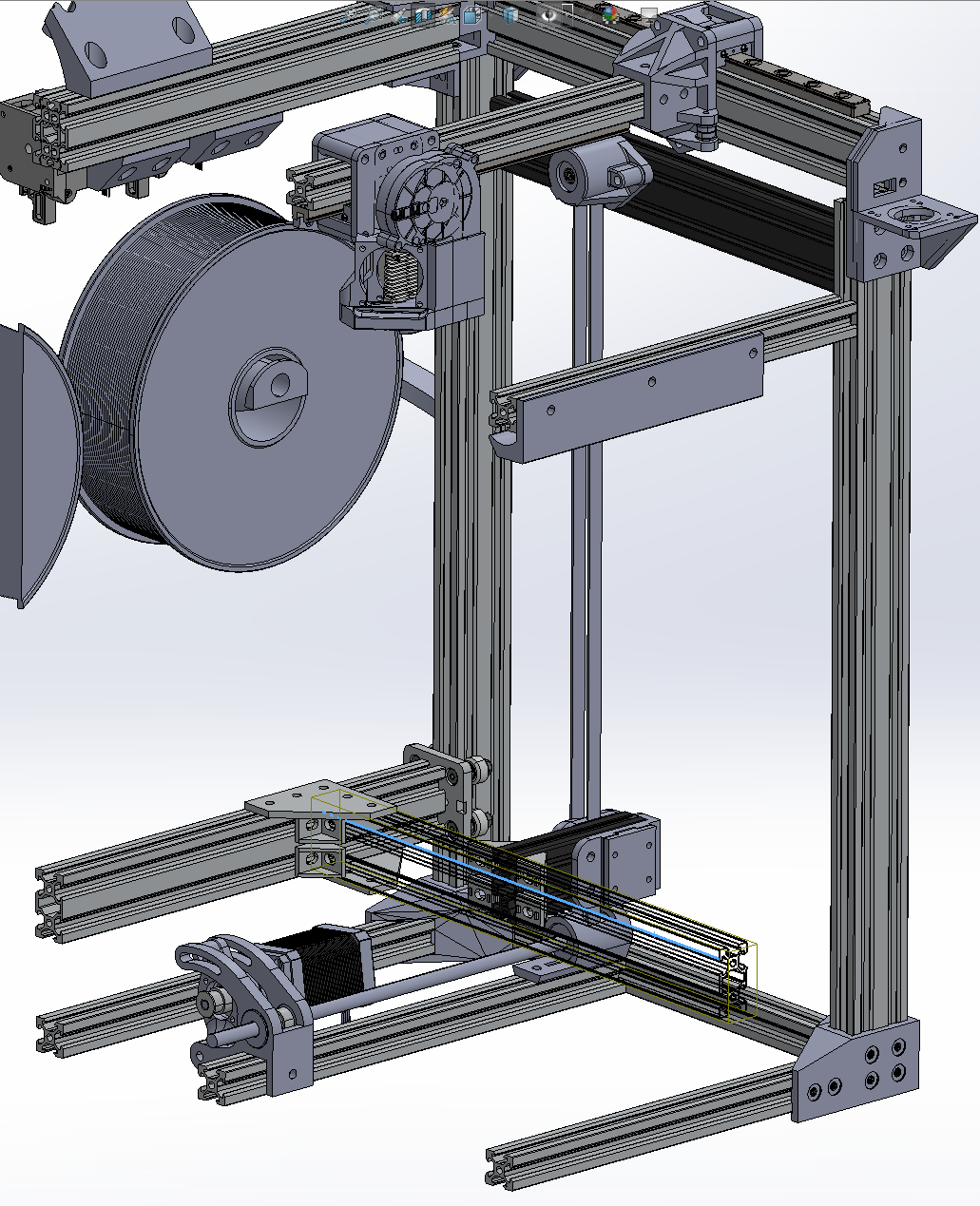

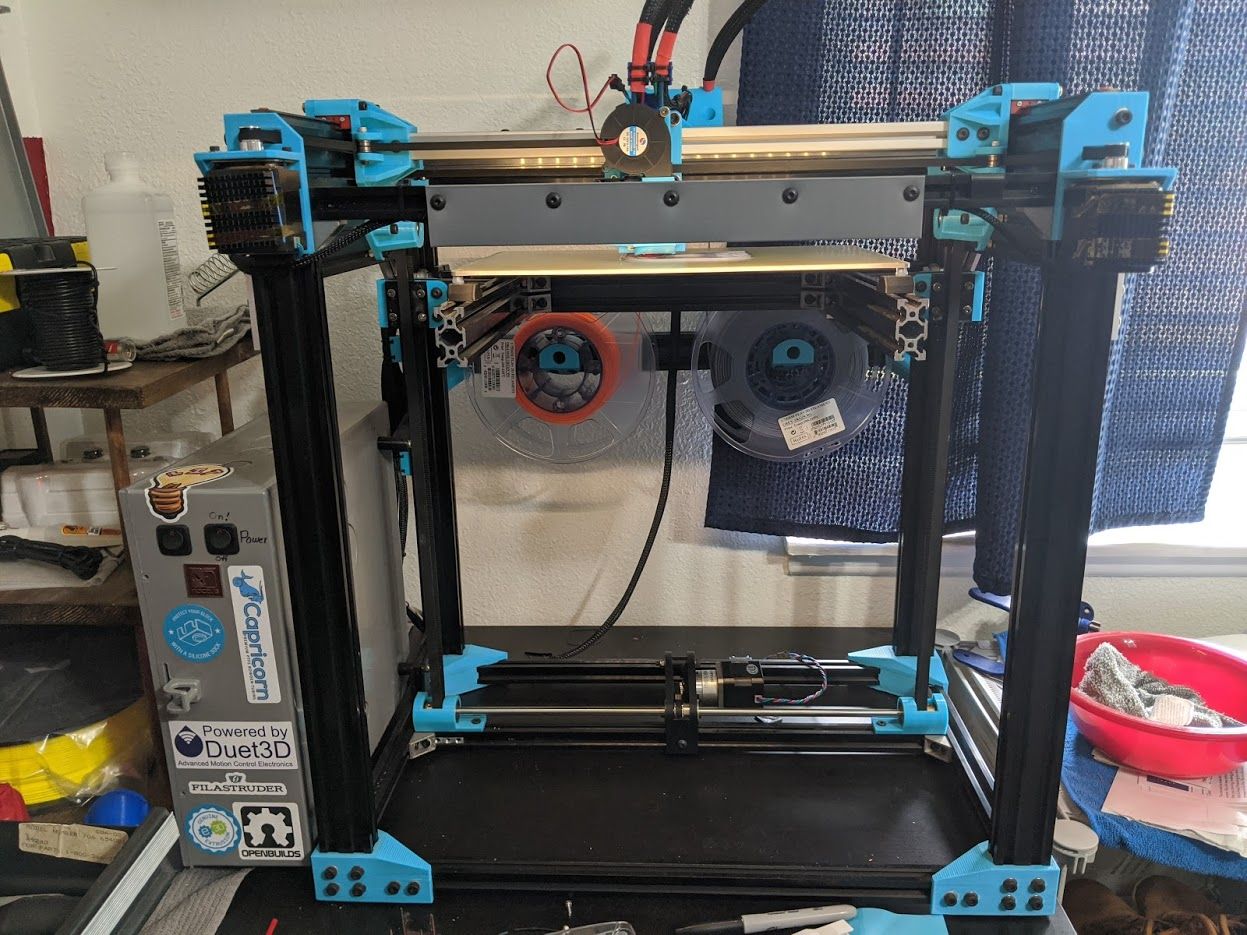

1st image is just to show the printer itself, before linear rails

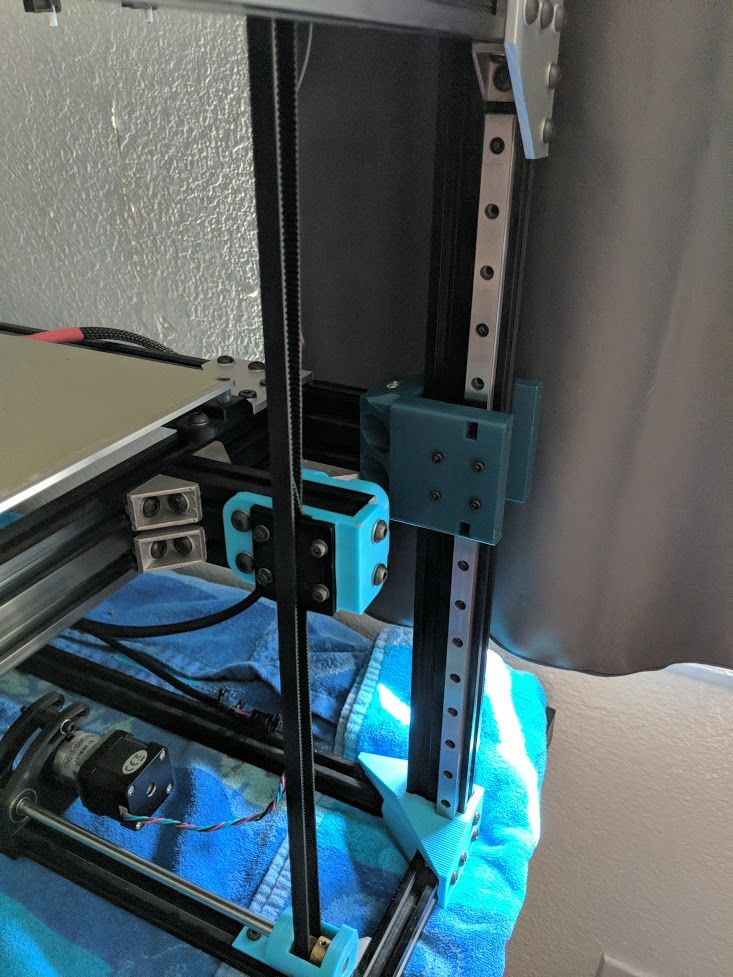

Now its got rails, and this is how they're mounted. Any advice on a better design is welcome. I'm no expert

-

@Turbo I expect that it is more important that the belt is placed nearer to the linear guide, because of the rule which is called 2:1 rule: https://www.machinedesign.com/mechanical-motion-systems/article/21836017/linear-bearings-understanding-the-21-ratio-and-how-to-overcome-the-stickslip-phenomenon

-

@JoergS5 it is indeed following the 2:1 rule.

-

@Turbo this is good.

The weight of the print bed is caught by the belt instead of the linear guide, so I would expect you have no win installing 2 additional linear guides. To the contrary, the risk to get stuck is much higher with 4 instead of 2 guides if they are not exactly precise parallel (to few micrometers). You can check (and correct) whether the weight focus of the bed is at the belt position. This would lower the force on the linear guide, so the guide fulfils only the taks to guide in the Z direction.

-

I don't think the 'linear' of linear rails is anything to do with load capacity, I think it relates to the fact that the rail permits linear movement.

The rail manufacturer might (ought to, but getting good spec details is difficult on lots of stuff made in china) (though that might be getting it in english is difficult) specify the capacity.

For an example of good detail, if it's genuine Hiwin: https://www.hiwin.com/pdf/linear_guideways.pdf

Page 89 of the file has the popular MGN12 rails, and show your rated moment for that type loading - if it's MGN 12H (which I pick only because that's what is on my delta) you've got a rating of 36 Nm. (Assuming I've udnerstood your photos right - I think you're worrying about what the data calls M.y).

If your lever arm is say 250mm and your load is say 2kg per bearing at that lever (figures I pluck from thin air), then you're applying 5 Nm, so you've got a factor of seven in hand.

I have no idea how the stated static rated load relates to actual in-service reliability, but a factor of seven seems likely to be sufficient. I observe that the basic load (which I assume is direct load perpendicular to the face of the carriage) has a factor of about 1.6 between static and dynamic. In teh absence of anything else, we could apply that, and your factor drops to 4.5.

None of this addresses flexibility though - even if the rail has sufficient strength, a cantilevering arrangement is possibly a good deal more flexible than a spanning arrangement.

-

@JoergS5 said in Do Linear Rails Perform Well Under Cantilever Loads?:

@Turbo this is good.

The weight of the print bed is caught by the belt instead of the linear guide,

Is it? Is there a belt carrying the weight at the far end of the member?

-

@achrn I think? the center of gravity or the bed and anything attached to it, is where the belts lie. I can (shouldn't, but i can) actually print without the linear guides due to the balance, but the ringing is comical.

-

@achrn I think so, the belts are carrying all the weight. The linear guide takes some of the load like a "inclined plane", .

-

@Turbo my recommeded two linear guides in total and belt in the middle of the focus weight would mean, the belt remains where it is (or where the middle of the bed is) and the linear rails left and right of the belts.

-

@Turbo said in Do Linear Rails Perform Well Under Cantilever Loads?:

@achrn I think? the center of gravity or the bed and anything attached to it, is where the belt lies. I can (shouldn't, but i can) actually print without the linear guides due to the balance, but the ringing is comical.

In that case I don't think there can be any (significant) moment on the guides, they are just being guides. I definitely wouldn't want to set up any opportunity for two linear guides to be fighting each other.

-

@achrn you could install two guides "fighting each other", but then better as in a CNC machine one as fixed bearing and floating bearing solution. But imho in this case there is not much win, because there is not much load.

-

-

@Turbo from my view, this is correct.

-

@JoergS5 Awesome, thanks for the input. I suppose i now need to convert my other printer to a linear rail z axis with my extra rails

-

@Turbo I like them, but there are quality differences. I discovered one yesterday which is rusted, it is worth to maintain them a bit.

-

@JoergS5 I find that keeping a thin layer of lubricant on the rails helps with rusting. But yeah I actually have some surface rust on some other rails that sat for some months I was gone and no one cleaned them at all. These are LDO Rails from Printed Solid's shop. 400mm. Good Stuff

-

Hi,

There many different designs out there in the real world, some good, some bad.

I had a DBot for a while but didn't like it's design, so I took it apart and started over.

I tried 4 guide rods (12mm dia) with two lead screws (8mm dia, 8mm pitch), one Z stepper, like my FT-5.

I tried 4 guide rods (12mm dia) with three lead screws (8mm dia, 8mm pitch) and three Z steppers for auto-leveling.

I now have 4 linear guides and two lead screws (12mm dia 2mm pitch), one Z stepper.

That is working pretty well but I'm still getting some minor Z banding (I think that is what it is).

My next experiment, if I get the motivation, is to try two lead screws (8mm dia, 8mm pitch) with attached steppers, to eliminate the belt in the current single stepper design which places a sideways load on the lead screws.

I may even try three of the lead screw/stepper combos and give auto-leveling another go.

I'm having fun.

Frederick

-

@fcwilt sounds like a fun project. Ever since I saw the Voron2, I've loved the idea of a belted Z axis, and it is really nice. No z banding to worry about assuming everything else it running smooth. Maybe consider what ive done and go belted. No lead screws to mess with

-

@Turbo said in Do Linear Rails Perform Well Under Cantilever Loads?:

@fcwilt sounds like a fun project. Ever since I saw the Voron2, I've loved the idea of a belted Z axis, and it is really nice. No z banding to worry about assuming everything else it running smooth. Maybe consider what ive done and go belted. No lead screws to mess with

I'm always up for trying different things.

How many belts? How many steppers?

Thanks.

Frederick

-

@fcwilt two belts. One stepper, which is geared 5:1, and a large rod to sync them up.

Here's a section view of one side.