What are the G Code commands that affect stepper feedrate?

-

@jcsb1994 I looked through your config again and besides the aforementioned missing

M201 Unnnvalue there is nothing obvious that would explain this.Can you please do the following:

- Run

M122(discard the result this is just for resetting various values) - Execute the move with one motor and make sure duration is as expected

- Run

M122and post the result - Execute the move with how many motors it takes to provoke longer than expected duration

- Run

M122and post the result together with the actual command

- Run

-

Also I suggest you send M350 without parameters to verify that the microstepping is still set to x16, and M203 without parameters to verify that the speed limits haven't changed from the values in config.g.

-

@jcsb1994 said in What are the G Code commands that affect stepper feedrate?:

A couple more config oddities, but probably doesn't explain the issue:

G91

You set G91 for relative movements. Do you change back to absolute movements at any point, with G90? Try replacing G91 with G90.

M208 A0:63 B0:63 U0:63 V0:63 W0:63 X0:63 Y0:63 Z0:63 E0:63 ; Set axis min-maxima

There's a number of axes there that are not defined. Comment out A, B, V, W and E (E axis doesn't usually have limit).

M92 X101.858 Y50.929 Z101.858 U50.929 ; Set steps per mm

You have defined the extruder, but haven't defined the steps per mm.

I find the positions that the printer stopped at very odd. Did you do some moves before running the script? I suppose it doesn't really matter, as you were using relative moves, but it is outside the bounds set by M208, though you have overridden it with M564.

G1 H1 X-25 Y-25 Z-25 U-25 F1500

In your move script, the H1 is unnecessary, as you're not homing (I think). If you run in absolute positioning (G90), change this toG1 X0 Y0 Z0 U0 F1500Is this your full config.g? If not, can you post the full config.g.

Ian

-

@wilriker said in What are the G Code commands that affect stepper feedrate?:

M122

Sorry for the late reply, I didnt have access to the board.

Here is the 1st move with the right speed (at the bottom) with M122 run right after it

8/6/2020, 9:42:33 AM M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.1.1 running on Duet WiFi 1.02 or later Board ID: 08DGM-917NK-F23T0-6J9DL-3SS6K-KW9SH Used output buffers: 3 of 24 (19 max) === RTOS === Static ram: 27980 Dynamic ram: 92936 of which 20 recycled Exception stack ram used: 328 Never used ram: 9808 Tasks: NETWORK(ready,468) HEAT(blocked,1456) MAIN(running,1840) IDLE(ready,80) Owned mutexes: === Platform === Last reset 00:03:49 ago, cause: power up Last software reset at 2020-08-03 10:30, reason: User, spinning module GCodes, available RAM 9872 bytes (slot 2) Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task MAIN Error status: 0 MCU temperature: min 28.7, current 29.2, max 29.4 Supply voltage: min 12.0, current 12.1, max 12.2, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: standstill, SG min/max not available Driver 1: standstill, SG min/max not available Driver 2: standstill, SG min/max not available Driver 3: standstill, SG min/max not available Driver 4: standstill, SG min/max not available Date/time: 2020-08-06 09:42:33 Cache data hit count 407286085 Slowest loop: 9.95ms; fastest: 0.12ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 0.9ms, write time 0.0ms, max retries 0 === Move === Hiccups: 0(0), FreeDm: 169, MinFreeDm: 168, MaxWait: 33253ms Bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves: 9, completed moves: 9, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === AuxDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === Heat === Bed heaters = -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 199.84ms; fastest: 0.09ms Responder states: HTTP(2) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 2 WiFi firmware version 1.23 WiFi MAC address b4:e6:2d:53:14:68 WiFi Vcc 3.45, reset reason Unknown WiFi flash size 4194304, free heap 22880 WiFi IP address 192.168.1.192 WiFi signal strength -64dBm, reconnections 0, sleep mode modem Socket states: 4 0 0 0 0 0 0 0 8/6/2020, 9:42:14 AM G1 H0 Y25 F1500Here is the slower move with 2 motors (running all 4 would be even slower) and M122 run right after it.

8/6/2020, 9:46:50 AM M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.1.1 running on Duet WiFi 1.02 or later Board ID: 08DGM-917NK-F23T0-6J9DL-3SS6K-KW9SH Used output buffers: 3 of 24 (19 max) === RTOS === Static ram: 27980 Dynamic ram: 92936 of which 20 recycled Exception stack ram used: 328 Never used ram: 9808 Tasks: NETWORK(ready,468) HEAT(blocked,1456) MAIN(running,1840) IDLE(ready,80) Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:08:06 ago, cause: power up Last software reset at 2020-08-03 10:30, reason: User, spinning module GCodes, available RAM 9872 bytes (slot 2) Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task MAIN Error status: 0 MCU temperature: min 29.0, current 30.4, max 30.6 Supply voltage: min 12.0, current 12.1, max 12.2, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: standstill, SG min/max not available Driver 1: standstill, SG min/max not available Driver 2: standstill, SG min/max not available Driver 3: standstill, SG min/max not available Driver 4: standstill, SG min/max not available Date/time: 2020-08-06 09:46:50 Cache data hit count 864652416 Slowest loop: 22.65ms; fastest: 0.12ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 1.0ms, write time 9.2ms, max retries 0 === Move === Hiccups: 0(0), FreeDm: 169, MinFreeDm: 167, MaxWait: 268218ms Bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves: 10, completed moves: 10, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === AuxDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === Heat === Bed heaters = -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 201.82ms; fastest: 0.09ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 3 WiFi firmware version 1.23 WiFi MAC address b4:e6:2d:53:14:68 WiFi Vcc 3.45, reset reason Unknown WiFi flash size 4194304, free heap 23320 WiFi IP address 192.168.1.192 WiFi signal strength -65dBm, reconnections 0, sleep mode modem Socket states: 4 0 0 0 0 0 0 0 8/6/2020, 9:46:44 AM G1 H0 X-25 Y-25 F1500@dc42

I tested both! They didn't change from config.g8/6/2020, 9:49:22 AM M203 Max speeds (mm/sec): X: 333.3, Y: 333.3, Z: 333.3, U: 333.3, E: 333.3, min. speed 0.50 8/6/2020, 9:48:53 AM M350 Microstepping - X:16(on), Y:16(on), Z:16(on), U:16(on), E:8(on) -

@droftarts Here is my config.g before I apply your changes:

; Configuration file for Duet WiFi (firmware version 1.23) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2 on Thu Feb 07 2019 21:56:57 GMT-0500 (Eastern Standard Time) ; General preferences ;G90 ; Send absolute coordinates M83 ; ...but relative extruder moves ; Network M550 P"JackTheRipper" ; Set machine name M551 P"notshowninforums" ; Set password ;M552 S0 ; Enable network : send to idle mode M552 S1 ; Enable network : establish connection ;M587 shouldn't be in config.g, use YAT instead to connect, then leave M552 S1 command to stay connected when repowering ;M587 S"notshowninforums" P"notshowninforums" ; Configure access point. You can delete this line once connected M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives G91 M584 X0 Y1 Z2 U3 E4 ;M584 A0 B1 U2 V3 ; map drives for first band M564 H0 S0 ; can move motors without homing, S0 can ignore axis limits M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M350 X16 Y16 Z16 U16 E8 I1 ; Configure microstepping with interpolation M92 X101.858 Y50.929 Z101.858 U50.929 ; Set steps per mm M566 X100.00 Y100.00 Z100.00 U100.00 E120.00 ; Set maximum instantaneous speed changes (mm/min) M203 X20000.00 Y20000.00 Z20000.00 U20000.0 E20000.00 ; Set maximum speeds (mm/min) Z wobbles at 800 M201 X1100.00 Y1100.00 Z1100.00 U1100.0 E1100.00 ; Set accelerations (mm/s^2); testing was done at 4500 4500 10 250 M906 X700.00 Y1400.00 Z700.00 U1400.00 E500.00 ; Set motor currents (mA) M84 S0 ; Disable motor idle current reduction ; Axis Limits M208 A0:63 B0:63 U0:63 V0:63 W0:63 X0:63 Y0:63 Z0:63 E0:63 ; Set axis min-maxima G92 X0 Y0 Z0 U0 ; set all position to 0 along axis ; Endstops ;M574 A1 B1 U1 V1 W1 X1 Y1 Z1 E1:1:1:1 S0 ; Set active low for all 8 motors on Jack M574 X1 S1 P"!xstop" ; A min active LOW endstop switch M574 Y1 S1 P"!ystop" ; B min active LOW endstop switch M574 Z1 S1 P"!zstop" ; U min active LOW endstop switch M574 U1 S1 P"!e0stop" ; V max active LOW endstop switch ; Z-Probe ;M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch ;M558 P9 H7 F120 T3000 ; Set Z probe type to bltouch and the dive height + speeds ;G31 P500 X-22 Y30 Z1.3 ; Set Z probe trigger value, offset and trigger height LAST BEST VALUE : Z = 1.5, Y = -30 ;M557 X0:250 Y0:300 S50 ; Define mesh grid ; Heaters M140 H-1 ; Disable heated bed ;M305 P0 B4725 C7.060000e-8 ; Set thermistor + ADC parameters for heater 0 ;M143 H0 S80 ; Set temperature limit for heatbed to 80C ;M305 P1 B4725 C7.060000e-8 ; Set thermistor + ADC parameters for heater 1 ;M143 H1 S280 ; Set temperature limit for heater 1 to 280C ;M305 P2 T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 2 ; Fans ;M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off ;M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 E0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Automatic power saving ;M911 S20 R21 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss ; Custom settings are not configured ; Miscellaneous ;M501 ; Load saved parameters from non-volatile memory SSID: EBOX-1731 Protocol: Wi-Fi 4 (802.11n) Security type: WPA2-Personal Network band: 2.4 GHz Network channel: 1 IPv6 address: fde0:83b6:6742:10::cb6 fde0:83b6:6742:10:21d1:ad:29e2:705 Link-local IPv6 address: fe80::21d1:ad:29e2:705%12 IPv6 DNS servers: fe80::3e90:66ff:fe53:4c90%12 IPv4 address: 192.168.1.205 IPv4 DNS servers: 192.168.1.1 DNS suffix search list: lan Manufacturer: Intel Corporation Description: Intel(R) Wireless-AC 9260 160MHz Driver version: 21.70.0.6 Physical address (MAC): 04-33-C2-76-E8-5F@droftarts said in What are the G Code commands that affect stepper feedrate?:

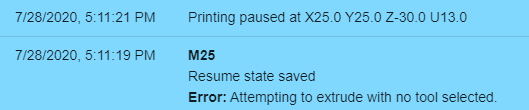

I find the positions that the printer stopped at very odd. Did you do some moves before running the script? I suppose it doesn't really matter, as you were using relative moves, but it is outside the bounds set by M208, though you have overridden it with M564.

If I inderstand correctly, the positions written here are the code from pause.g?

@bearer said in What are the G Code commands that affect stepper feedrate?:

you pressed pause and the duet ran pause.g which by default contain some retraction g-code...

@droftarts said in What are the G Code commands that affect stepper feedrate?:

In your move script, the H1 is unnecessary, as you're not homing (I think). If you run in absolute positioning (G90), change this to G1 X0 Y0 Z0 U0 F1500

The H1 lets my endstops stop my move. This is true with G90 and G91. When I put H0 or nothing at all the motor tries to run passed the endstop.

This is the new config.g. The problem isnt solved, but I dont like G91 at all it is messy for sending displacements of a specific distance haha!

; Configuration file for Duet WiFi (firmware version 1.23) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2 on Thu Feb 07 2019 21:56:57 GMT-0500 (Eastern Standard Time) ; General preferences G90 ; Send absolute coordinates... not for jack M83 ; ...but relative extruder moves ; Network M550 P"JackTheRipper" ; Set machine name M551 P"llolollol" ; Set password ;M552 S0 ; Enable network : send to idle mode M552 S1 ; Enable network : establish connection ;M587 shouldn't be in config.g, use YAT instead to connect, then leave M552 S1 command to stay connected when repowering ;M587 S"iiiiiiiii" P"aaaaaaaa" ; Configure access point. You can delete this line once connected M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives ;G91 M584 X0 Y1 Z2 U3 ;M584 A0 B1 U2 V3 ; map drives for first band M564 H0 S0 ; can move motors without homing, S0 can ignore axis limits M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M350 X16 Y16 Z16 U16 E8 I1 ; Configure microstepping with interpolation M92 X101.858 Y50.929 Z101.858 U50.929 ; Set steps per mm M566 X100.00 Y100.00 Z100.00 U100.00 E120.00 ; Set maximum instantaneous speed changes (mm/min) M203 X20000.00 Y20000.00 Z20000.00 U20000.0 E20000.00 ; Set maximum speeds (mm/min) Z wobbles at 800 M201 X1100.00 Y1100.00 Z1100.00 U1100.0 E1100.00 ; Set accelerations (mm/s^2); testing was done at 4500 4500 10 250 M906 X700.00 Y1400.00 Z700.00 U1400.00 E500.00 ; Set motor currents (mA) M84 S0 ; Disable motor idle current reduction ; Axis Limits M208 X0:63 Y0:63 Z0:63 U0:63 ; Set axis min-maxima G92 X0 Y0 Z0 U0 ; set all position to 0 along axis ; Endstops ;M574 A1 B1 U1 V1 W1 X1 Y1 Z1 E1:1:1:1 S0 ; Set active low for all 8 motors on Jack M574 X1 S1 P"!xstop" ; A min active LOW endstop switch M574 Y1 S1 P"!ystop" ; B min active LOW endstop switch M574 Z1 S1 P"!zstop" ; U min active LOW endstop switch M574 U1 S1 P"!e0stop" ; V max active LOW endstop switch ; Z-Probe ;M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch ;M558 P9 H7 F120 T3000 ; Set Z probe type to bltouch and the dive height + speeds ;G31 P500 X-22 Y30 Z1.3 ; Set Z probe trigger value, offset and trigger height LAST BEST VALUE : Z = 1.5, Y = -30 ;M557 X0:250 Y0:300 S50 ; Define mesh grid ; Heaters M140 H-1 ; Disable heated bed ;M305 P0 B4725 C7.060000e-8 ; Set thermistor + ADC parameters for heater 0 ;M143 H0 S80 ; Set temperature limit for heatbed to 80C ;M305 P1 B4725 C7.060000e-8 ; Set thermistor + ADC parameters for heater 1 ;M143 H1 S280 ; Set temperature limit for heater 1 to 280C ;M305 P2 T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 2 ; Fans ;M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off ;M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 E0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Automatic power saving ;M911 S20 R21 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss ; Custom settings are not configured ; Miscellaneous ;M501 ; Load saved parameters from non-volatile memory SSID: EBOX-1731 Protocol: Wi-Fi 4 (802.11n) Security type: WPA2-Personal Network band: 2.4 GHz Network channel: 1 IPv6 address: fde0:83b6:6742:10::cb6 fde0:83b6:6742:10:21d1:ad:29e2:705 Link-local IPv6 address: fe80::21d1:ad:29e2:705%12 IPv6 DNS servers: fe80::3e90:66ff:fe53:4c90%12 IPv4 address: 192.168.1.205 IPv4 DNS servers: 192.168.1.1 DNS suffix search list: lan Manufacturer: Intel Corporation Description: Intel(R) Wireless-AC 9260 160MHz Driver version: 21.70.0.6 Physical address (MAC): 04-33-C2-76-E8-5FShould I send a video of what is happening?

-

Yesterday I tried with the slowest speed possible, I was sending 25mm movements with a feedrate of 300 (i.e. G1 X25 Y25 Z25 U25 F300) and was also slowed by a similar factor. I had around 8 seconds instead of 5 per move when moving more than one motor.

That makes me think that it clearly is a software setting somewhere that slows it down? Or it just cant compute more than one motor? Since it is slowed down even more when the command I sent it should already be going slower than the speed it used to go to when I was asking 1500 feedrate, I doubt it can be hardware related.I am starting to lose hope on what else I can do to solve this. I already read the whole G code page in search for useful settings.

-

The H1 lets my endstops stop my move. This is true with G90 and G91. When I put H0 or nothing at all the motor tries to run passed the endstop.

H1 is to be used when homing as it will set the axis position to axis min/max (depending on the location of the end stop sensor) when the end stop sensor is activated.

You don't use it just to try and solve a problem with moving past the axis min/max.

If normal moves are not limited to the axis min/max perhaps you have a M564 somewhere disabling the min/max limit. You could also have a problem with your homing code or your motor steps/mm settings.

I dont like G91 at all it is messy for sending displacements of a specific distance haha!

What does that mean?

Thanks

Frederick

-

@fcwilt said in What are the G Code commands that affect stepper feedrate?:

The H1 lets my endstops stop my move. This is true with G90 and G91. When I put H0 or nothing at all the motor tries to run passed the endstop.

H1 is to be used when homing as it will set the axis position to axis min/max (depending on the location of the end stop sensor) when the end stop sensor is activated.

You don't use it just to try and solve a problem with moving past the axis min/max.

If normal moves are not limited to the axis min/max perhaps you have a M564 somewhere disabling the min/max limit. You could also have a problem with your homing code or your motor steps/mm settings.I removed my M564 command and tried using my home files instead, but no luck. My steps/mm settings are fine, at least I think so since my axes movement distances

I dont like G91 at all it is messy for sending displacements of a specific distance haha!

What does that mean?

I meant the opposite, sorry! I always have to calculate the motors position before sending a command with G90. I am interested in moving the motors for particular distances, so G91 is much easier for me.At that point, either it is due to the newer firmware, or my duet is broken!

-

Hi,

This is not related to your problem but it can help those trying to help.

If you set your forum signature you can put your hardware and/or firmware information there so everyone knows at a glance.

Frederick

-

@jcsb1994 I don't know if you are still working on this but I think I was having the same issues. I never actually timed the moves on the 2.x firmware but it seemed like the moves completed in the correct amount of time. When I updated to the 3.1.1 firmware my motors went way faster than they were supposed to. So I think they changed how the feedrates are calculated.

Now I think that the feedrate is only calculated using the X, Y, and Z values. Meaning that with your initial example of G1 X-25 Y-25 Z-25 U-25 F1500 to find out how long the move is going to take you first need to find how long the diagonal move will be.

This will be 25^2 + 25^2 + 25^2 = c^2, c will equal 43.3. Then you divide by the feedrate and multiply by 60 to get the length of time the move will take in seconds. Meaning that the time for this move should be 1.73 s. I did the math for the feedrate of 300 as well and I got that the move should take 8.66 s.

The math seems to match what you are getting but it would be nice to confirm that this is actually what is going on and see if these changes were implemented when updating to firmware 3.x.