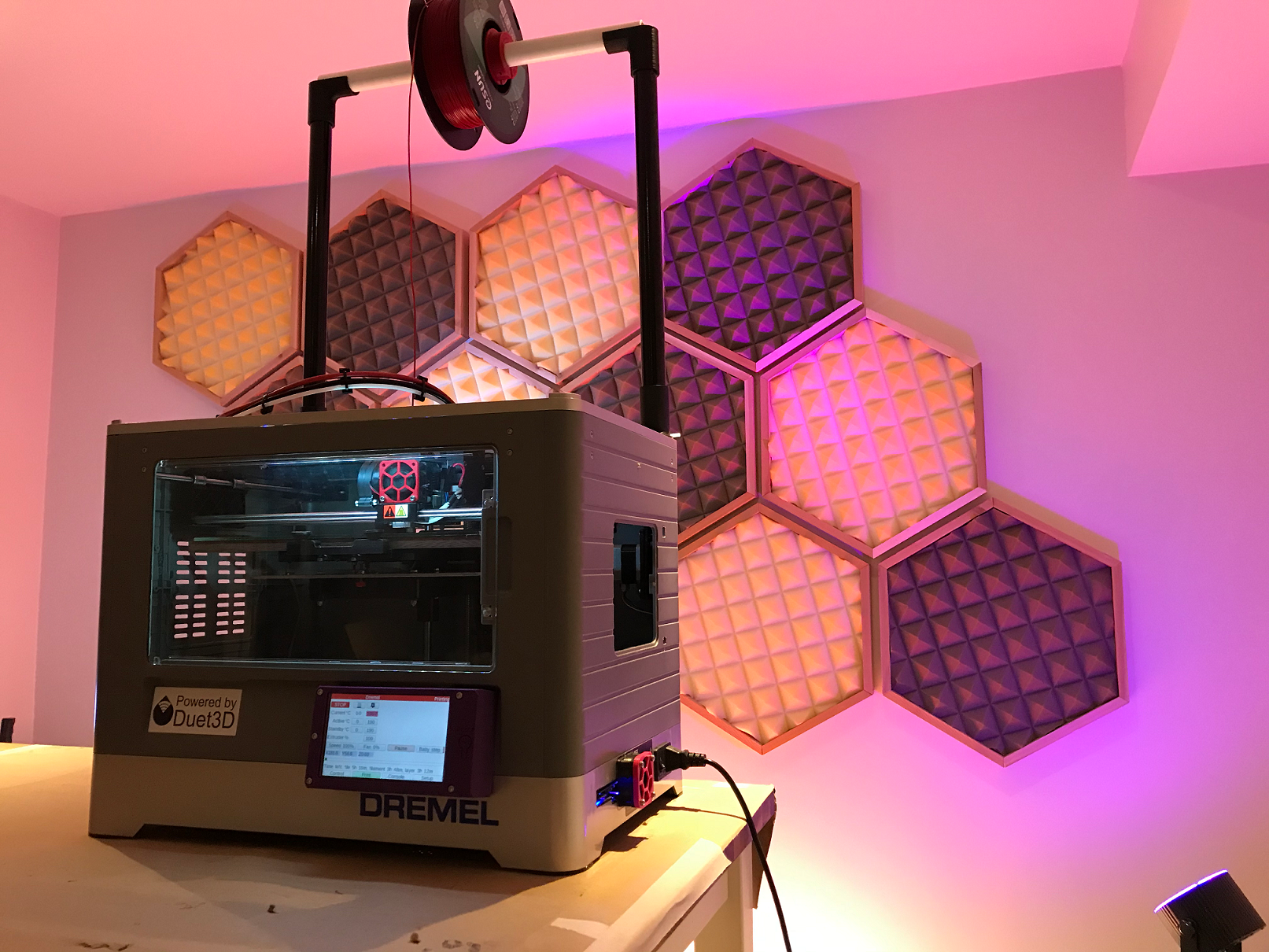

Dremel 3D20: Duet 2 Wifi, PanelDue, kinematic bed, hot swap PCB

-

I converted a Dremel 3D20 printer (similar to Makerbot Replicator, Wanhao Duplicator, Flashforge Inventor) to Duet 2 Wifi control, Panel Due 5" touch screen, kinematic mount bed levelling system, custom spool holder, all metal hot end, and a hot swap PCB hot end.

The original printer was getting hung up around the same layer and exhibiting some other strange behaviors. Some of the hot end wiring was also shorting out. It was destined for scrap but I found that the mechanical parts of the printer were overall pretty solid and it was a decent printer despite being old (2014?). I figured the control system was the first thing that needed to go and it sort of snow balled from there...

I made the design files available for people with similar printers:

Duet Wifi Mount, Due Panel 5" Mount, End Stop Modifiers, Power Supply Adapters:

► https://www.thingiverse.com/thing:4637810Kinematic Mount Bed Levelling System:

► https://www.thingiverse.com/thing:4637799Three point bed levelling system using kinematic mount principles.

I designed this for use with a Dremel 3D20 printer but should also work on flashforge inventor or Wanhao / Makerbot variants of the same printer, possibly with some modifications.PVC Spool Holder:

► https://www.thingiverse.com/thing:4637764SimplePVC spool holder to adapt 3/4" Schedule 40 PVC pipe to hold filament above your printer for the most direct and restriction free feed.

The feet can be screwed to your work table, printer enclosure, shelf, etc and two PVC pipe will be fitted upright. The elbows hold a horizontal piece of PVC in place. It can be easily lifted for quick removal of filament.

The bearing and collars adapt the PVC OD to the eSUN filament ID of the spool. The collars keep the spool centered on the PVC pipe. They are intended to be a light friction fit over the PVC pipe to stay in place. Screws can be added if more friction is desired to clamp the collars tightly around the pipe.

Hot End Parts and Schematic:

► https://www.thingiverse.com/thing:4637780The hot swap PCB accommodates 2 part cooling fans, 1 extruder fan, 1 aux connection, thermistor, heater cartridge (24V only, 40W max), and the extruded motor connections.

RJ45 jacks are required to accept the network cables (should be cat5e with 24AWG stranded wire, unshielded twisted pair). Any 2.54mm (0.1") connectors should fit the other connection locations. (I used JST connectors for my printer).

350W 24V Power Supply:

► https://www.digitmakers.ca/products/mean-well-12v-24v-power-supply?variant=10053946671140Heater Block:

► https://www.digitmakers.ca/products/mk10-heater-blockMicroSwiss Hot End:

► https://www.digitmakers.ca/products/all-metal-mk10-hot-end-0-4-mm-b-upgrade-b-by-micro-swissE3D Thermistor:

► https://www.digitmakers.ca/products/e3d-thermistor-cartridge24V 40W Heater Cartridge:

► https://www.digitmakers.ca/products/genuine-e3d-heater-cartridge-12-24-volts?variant=9205741191204RJ45 Jack for PCB:

► https://www.digikey.com/en/products/detail/amphenol-icc-fci/54602-908LF/1001360

-

@doublec4 nice! thanks for detailing the upgrades.

-

You're welcome. This forum was very helpful in getting a few of the details sorted out with the controller... as I dive into deeper I'm sure I will have more questions!