very strange Lines on Prints - Firmware issue?

-

@Phaedrux Yes. I tried PID as well as Bang-Bang but no luck. However I switched back to Bang bang since the PWM signal from the PID control caused more audible noise.

Edit: I am not sure I covered this explicitly in my tests. I will rerun this right now, to be 100% sure.

-

Do a test print with the bed heater off entirely to verify.

-

@Phaedrux good idea!

-

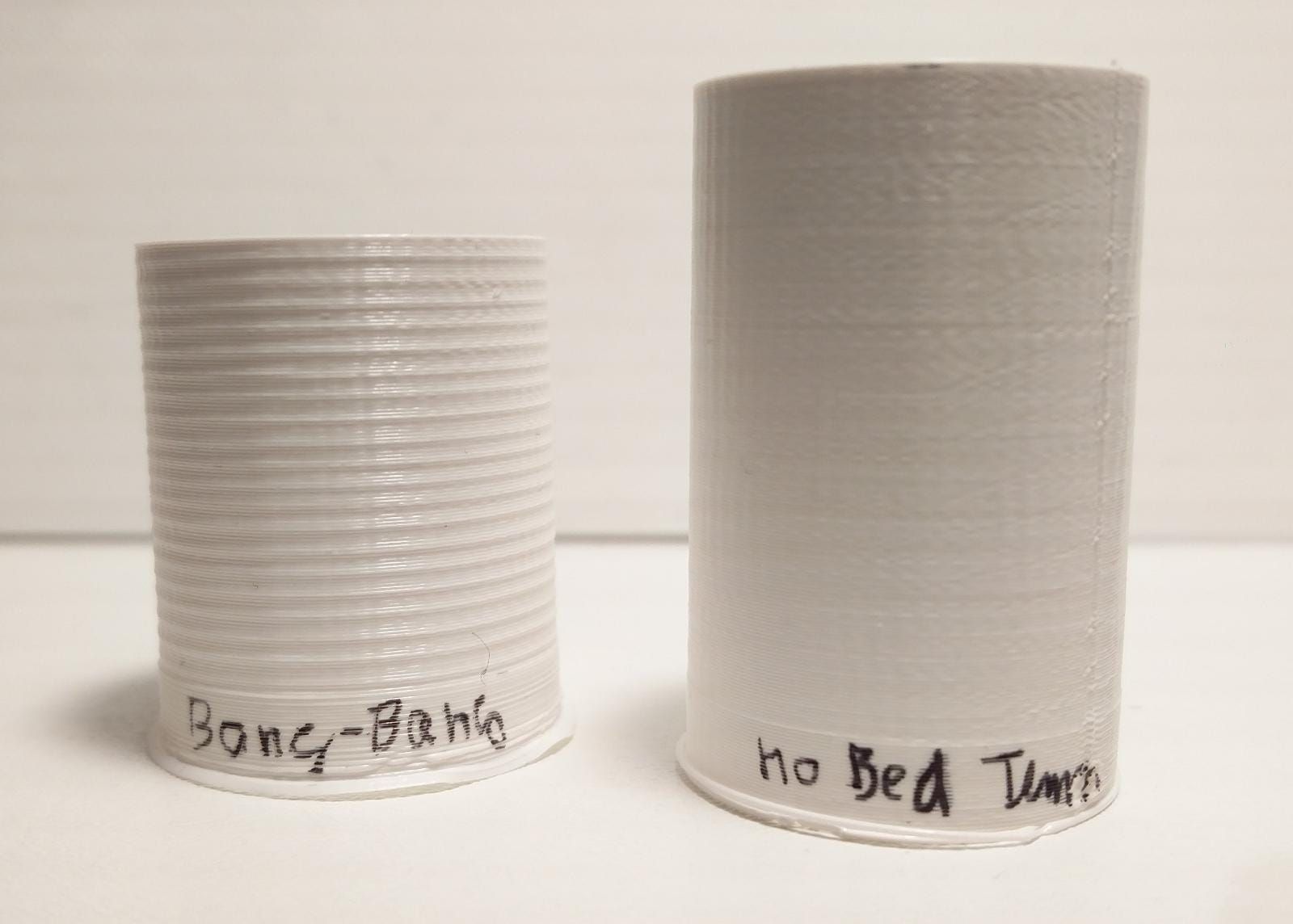

I did Some tests now, and on the first one was still some decent Z banding - but in a random order!

Then I placed a model right in the middle of the bed (if it would be because of thermal expansion, then it should be most visible there, I think) and run a test without and with Bed heating (Bang-Bang).Hell YEAH! This was it!

@Phaedrux can I offer you a Coffee?Fun fact: I measured the cycle time for the Bed heater turning on: It takes between 15-17 Seconds

So the next question is: Does PID solve the problem entirely?

And how common is this problem? I searched a lot for types of z wobble, but this one is new to me, although it makes a lot of sense.Edit: Is there a way to change the name of the topic (or mark it as solved)?

-

Cool!

Have you tried printing in a corner of the bed?

-

@theruttmeister yes. I did most of my testprints in the corner. However with Bang-Bang ON it is still noticeable. I am trying it now it PID PWM mode.

-

it look like Z banding like some said. threaded rod must be flexing under the weight

-

@Dad003 I think the remaining artifacts could be to some amount z-wobble. However, the biggest point was definitely the Bang-Bang Mode.

Now here is something interesting: I changed to PID-Mode and the wobble is very present like in Bang-Bang mode! I'm running a new auto tune run now. I hope, that helps.

-

PID tuning should help quite a bit by keeping the temp steady, but from what I know about the Tronxy bed is that it's very large and very thin and when current is applied it causes it to deform. I would think that once the bed is at temp and stable it shouldn't be much of a problem.

You can also experiment with different PWM frequencies in the M950 command for the bed heater.

Q500 is the default. Can try higher or lower.

Also make sure you're tuning the bed from cold.

-

I used M307 with the Fnnn parameter to set the frequency without luck. But Qnn on M950 works! Thanks @Phaedrux !

Running now inaudible at 20 Hz.

Does anybody know if this could be unhealthy for the PSU Capacitors? -

A number of years ago when i was printing on a thick aluminum plate 12mm cast fixture plate i was having the same issue using bang bang for the bed heater. If you put a dial indictor on the place you will actually see the dial indicator moving up to .2mm during heating. I changed the bed heater to PID and the issue was greatly reduced. One issue with aluminum is the thermal expansion which is why i have gone to borosilicate glass and all the expansion problems went away.