z motor not driving when connected to leadscrew

-

I'm building a printer using the duet wifi. It uses a dual leadscrew setup. I have nothing in the firmware that specifies dual z motors because they are wired in parallel to a single driver. When I do a x home only one motor turns for the hop but the other doesn't. I tried without the leadscrews attached and both motors turned. And then I tried removing the leadscrew from the motor that originally wasn't turning and keeping the other leadscrew on. After running the z hop for the x homing again and the motor without the leadscrew (original test was not working) spun fine. But the other motor(original test was working perfectly) did not spin. I have plenty of power to run all of the 8 motors on the printer. And both of the motors are the same model and lifting similar loads with the same leadscrew I am very stuck. If anyone has any thoughts on what the problem may be, it would be greatly appreciated. If not, thank you for your time.

-

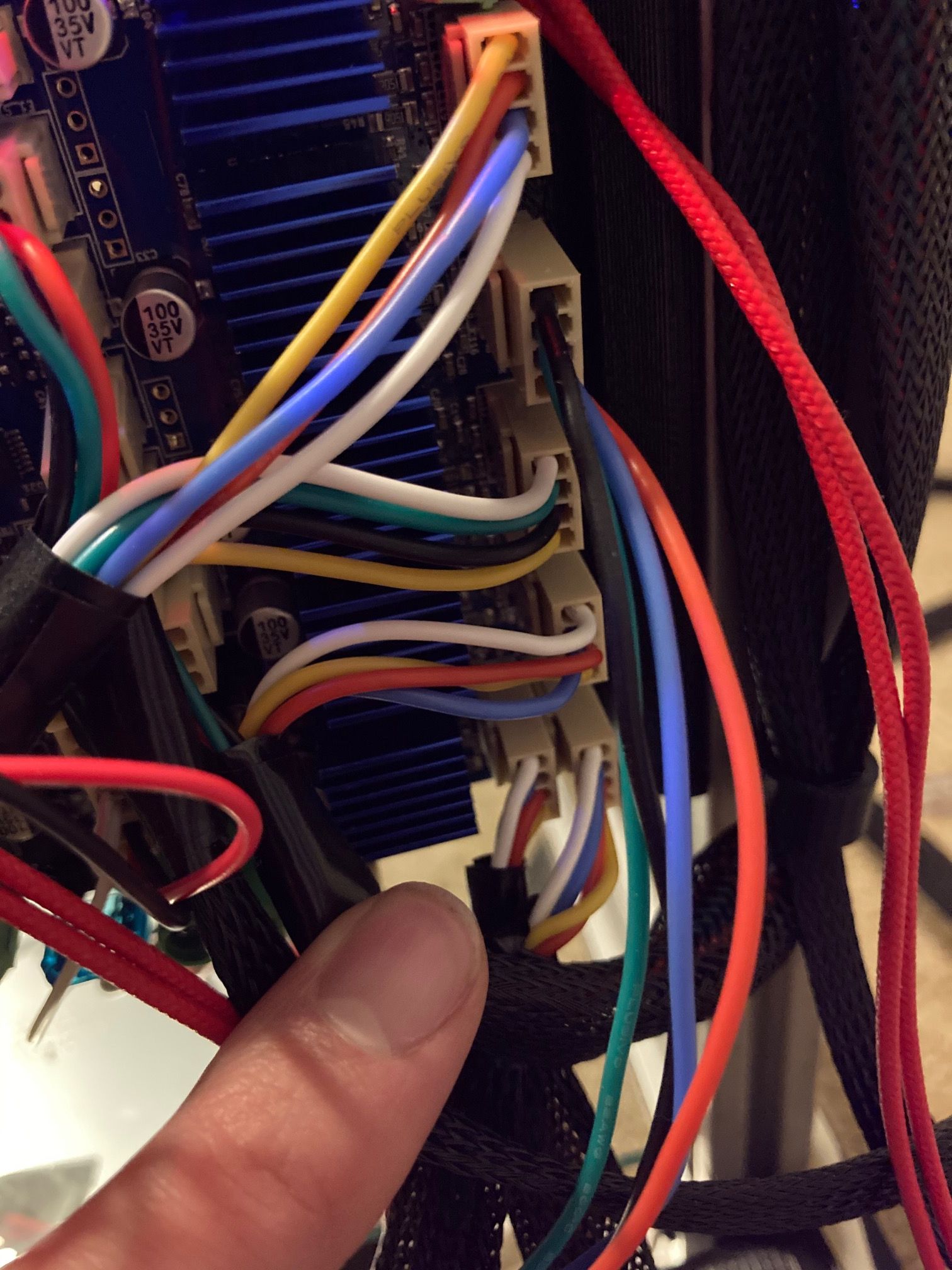

post your config.g and a photo of your wiring and the gcode you're trying to execute?

-

There is no specific gcode I am trying to run, this just happens with any type of z move so I have been using the z hop of the x home to test.; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes Backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S0 ; physical drive 3 goes forwards

M584 X0 Y1:4 Z2 E3 ; physical drive 4 goes Backwards

M350 X16 Y16:16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00:80.00 Z1600.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00:900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00:600.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00:500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800:800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X950 Y650 Z500 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y2 S1 P"ystop+e1stop"; Z-Probe

M950 S0 C"exp.heater7" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H10 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X50:900 Y50:600 S50 ; define mesh grid; Heaters

M143 S265 ; Set maximum heater temperature to 265C

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H T45 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Custom settings

M552 S1 -

@Ian-Miller said in z motor not driving when connected to leadscrew:

M350 X16 Y16:16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00:80.00 Z1600.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00:900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00:600.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00:500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800:800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeoutYou don't need the double values for Y. It's per axis, and not per motor.

Which drivers are you using for which axis?

Your photo shows two motors connected to driver 4, but your config shows Y is using driver 1 and 4.

-

So essentially this printer has 2 Y axis drivers because I'm trying to set them up to use independent endstops to home themselves then drive together for the combined y motion. Each one of those drivers drives 2 motors witch are wired in parallel. Witch is why I thought i needed the double values for y because I'm trying to make the printer use one of the unused extruder drivers to to drive the 2nd set of y drivers. I'm using every driver on the board for its intended axis except for E1 witch is the other side of the Y. And to answer your last question, I don't know how the drivers are numbered but as I said all but E1 is used as the board diagram shows.

-

@Ian-Miller said in z motor not driving when connected to leadscrew:

dual z motors because they are wired in parallel

the default wiring on the duet is for the two z motors to be in series, if you have wired them in parallel instead you should probably increase the current as its now shared between the motors. (although if the board is a 1oz copper clone you might not want to push the drivers too hard)

-

Sorry I misspoke the z motors are wired to the board as is standard. But for the Y motors they are wired in parallel 2 motors to a single driver.

(sorry for the confusion)

The power supply is a standard cr-10 power supply and should have more than enough power for the motors.

Additionally if it would help to upload a video of the problem I can do that. -

@Ian-Miller said in z motor not driving when connected to leadscrew:

The power supply is a standard cr-10 power supply

would probably help to know if its a 24v or 12v supply for those of us wihtout a cr-10, motors in series will benefit from higher supply voltage as they have to share the voltage while the current is the same through each motor

-

Its a 12v power supply

-

Ignoring the Y axis setup.

I'd start with increasing the current to Z, it sounds like there isn't enough power to turn both motors.

If that doesn't fix it I'd check the Z motor wiring, bad crimps are a common cause of intermittent motor issues.

Are you getting any error messages? The Duet will normally detect when most of the common issues with the drivers/motors happen and give you an error in DWC or via the PanelDue. I assume you are using DWC?

And can you post your homex.g ? Its probably not that, but it what you are running to generate the issue.

-

How would I go about increasing the current? Is there a potentiometer that I should use on the board to do that?

Additionally would it be worth trying to wire them both to a single set of pins on the board so they got equal current? -

@Ian-Miller said in z motor not driving when connected to leadscrew:

M906 X800 Y800:800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

Change Z800 to f.ex. Z1200 to change current from 0.8A to 1.2A.

But as the motors are wired in series they're already receiving 0.8A (each) like all the other motors. It would be the power supply voltage limiting the speed they can run at compared to the single motors.

-

I did what you asked about increasing the current. Each motor is only rated to 0.33 amps. Each motor is working intermittently and is is active but failing. The motors themselves should be able to lift the load. I will be checking the crimps and doing a little test with any tension on the leadscrews. Just to help I'm providing a video of the printer. IMG-5149-1.mp4

-

Tested with multimeter and redid wiring, the motors are able to drive both ways but function is still intermittent.

error message says 12/27/2020, 1:57:12 PM G28 X

Warning: motor phase A may be disconnected reported by driver(s) 2

Warning: motor phase B may be disconnected reported by driver(s) 2Homex.g

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-955 F1800 ; move quickly to X axis endstop and stop there (first pass)

G1 H2 X5 F6000 ; go back a few mm

G1 H1 X-955 F360 ; move slowly to X axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioningAdditionally I have problems with some endstops as well but I'm trying to figure those out myself but that's why the homing for x isn't happening.

-

@Ian-Miller said in z motor not driving when connected to leadscrew:

Warning: motor phase A may be disconnected reported by driver(s) 2

Warning: motor phase B may be disconnected reported by driver(s) 2would suggest the wiring is questionable or motors have high inductance (in which case you'll need to not run them in series or increase the supply voltage)

-

@Ian-Miller said in z motor not driving when connected to leadscrew:

Each motor is only rated to 0.33 amps.

Those are quite small motors. How much does the gantry weigh? How much compliance is there in the gantry? When they aren't perfectly even they are likely binding a bit and the motors aren't very powerful. I think they may not be suitable for your Z axis. Do you have the specs for them?

-

I tried wiring them in parallel and now neither motor activates whatsoever, but I will work on that.

As for the motor specs I will post them below. The entire gantry the 2 motors are lifting is between 2.5 and 3 pounds.

-

I can't make anything out on that blurry image.

-

are you aware that you have bought a cloned board?

those motors are not suitable for 3d printers

https://images-na.ssl-images-amazon.com/images/I/A1N+z7VtiNL.pdf

see

https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motorsAvoid motors with rated voltage (or product of rated current and phase resistance) > 4V or inductance > 4mH.

-

I did not realize that those motors were not ok with 3d printers, I'm using them for driving every other axis on this machine and they all 5 seem to be working well. Do you recommend I just get new motors for that axis or is there anything else I can try?

Btw thank you guys for all the tips and ideas, I'm only 15 and this is my first fully custom printer build.