Faults trying to configure thick print bed

-

@p8blr said in Faults trying to configure large print bed:

It's an E3D Cartridge thermistor.

that makes no sense

i have not seen a bed that accepts those.Version 3.1.1

update to 3.2

-

@Veti It's a printer that I built myself.

I found this https://e3d-online.dozuki.com/Guide/V6+RepRap+Firmware+Configuration/26?lang=en

Trying to figure out what my values will be...

-

@Veti said in Faults trying to configure thick print bed:

E3D Cartridge thermistor.

so you taped on of those to your bed?

these are the thermistors from e3d that are meant for beds

https://e3d-online.com/products/100k-ohm-ntc-thermistor-semitec?_pos=6&_sid=4dfe4ab04&_ss=r -

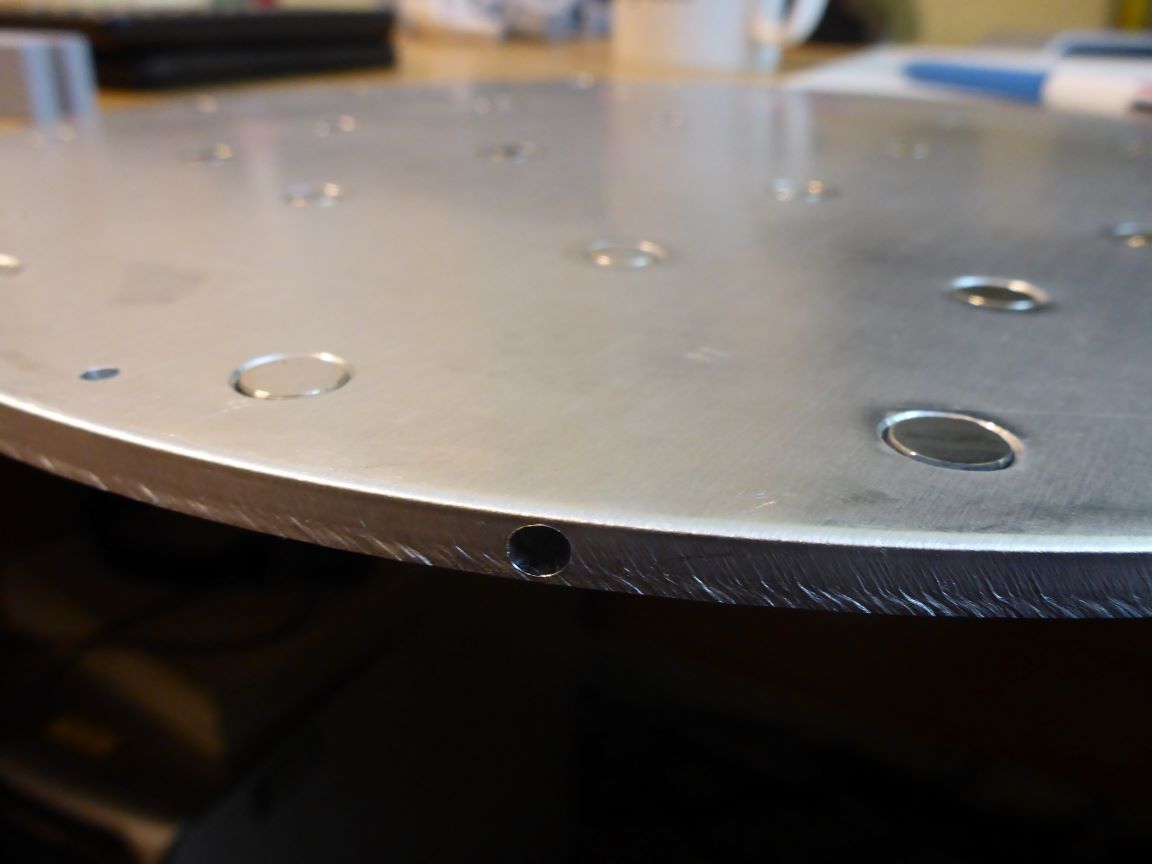

@Veti I machined a pocket in my bed and have it mounted internally near the print surface. I chose the cartridge style because it came with a micro-molex connector so it would be easy to replace.

Going off this post:

https://forum.duet3d.com/topic/9851/confusion-about-semitec-104gt-2-b-value-in-documentationMy new values will be:

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C0.0000000706

And I will also try to update the firmware next.

-

I was able to get it working and I just wanted to post what I did.

-Updated firmware to 3.2

-Changed B and C settings for my thermistors

-Ran autotune and it worked this timeThis is the new M308 Settings:

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 0 as thermistor on pin bedtemp, E3D cartridge thermistor

M308 S1 P"e0temp" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin e0temp, Slice Engineering Mosquito Thermistor

M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 2 as thermistor on pin e1temp, E3D cartridge thermistorAnd these are the new PID Values in config_override:

M307 H0 R0.179 C1487.194:1487.194 D74.62 S1.00 V24.0 B0Thanks.

-

@p8blr said in Faults trying to configure thick print bed:

And these are the new PID Values in config_override:

M307 H0 R0.179 C1487.194:1487.194 D74.62 S1.00 V24.0 B0You likely know this already but I will mention just to be safe.

If you don't like having configuration values in two files you can always move the contents of config_override.g into config.g at any locations in the file you deem appropriate.

Frederick

-

@Veti For info, I too use an E3D cartridge style thermistor on my bed. It sits inside a 3mm diameter hole, about 30mm deep, that I drilled in the edge of the

bed10mm thick aluminium plate so that the thermistor is de-coupled form the heat pad/aluminium plate junction. The hole is also as close to the top surface as I could get it without braking through - so the sensor reads the temperature where it matter. -

@p8blr said in Faults trying to configure thick print bed:

I was able to get it working and I just wanted to post what I did.

-Updated firmware to 3.2

-Changed B and C settings for my thermistors

-Ran autotune and it worked this timeThis is the new M308 Settings:

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 0 as thermistor on pin bedtemp, E3D cartridge thermistor

M308 S1 P"e0temp" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin e0temp, Slice Engineering Mosquito Thermistor

M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 2 as thermistor on pin e1temp, E3D cartridge thermistorAnd these are the new PID Values in config_override:

M307 H0 R0.179 C1487.194:1487.194 D74.62 S1.00 V24.0 B0Thanks.

That's an incredibly long dead time. Can you tell us a little more about the dimensions of the bed and the thermistor mounting "pocket" - especially how it is orientated with respect to the heater pad?

BTW, I use a 400mm / 400mm x 10mm thick plate with an 800 watt heater - for the sake of comparison, here is my latest tuning result using RRF3.2

M307 H0 R0.104 C2186.5 D28.16 S1.00 B0 V0Edit. Mine is a mains powered heater via an SSR - I guess yours is 24V yes?.

-

@Veti as @deckingman said, and it works well:

Mine is about 40mm deep, 3.5mm diameter hole in a 6mm thick bed plate. Actually at the moment it has a PT100 cartridge in it, but it could take a thermistor cartridge.

My D is about 46. I think if you are measuring temperature of the plate (rather than of the heater element) you'd expect a longer dead time.

M307 H0 R0.243 C1212.7 D46.41 S1.0 V0 B0 -

I have no problem with the duet software with a heat bed of 12mm thick aluminum and heat bed with 10mm Showing results for borosilicate glass

Bother were 300mm X 600mm. You need to make sure that your heater is able to get up to temperature quick enough. I am using a mains powered heater. -

it will take a lot of time for the heat to reach the outer edge.

that is prob partly the reason for the long dead time. -

@Veti said in Faults trying to configure thick print bed:

it will take a lot of time for the heat to reach the outer edge.

that is prob partly the reason for the long dead time.Depends on the size of the heat pad and how deep the hole is.

-

@Veti said in Faults trying to configure thick print bed:

it will take a lot of time for the heat to reach the outer edge.

that is prob partly the reason for the long dead time.I haven't got access to a thermal camera to check the coolness at the edges, but the sensor cartridge is well inside the footprint of the heater element (in mine, at least). The heat doesn't have to spread outwards, only through the plate.