PT100 sensor on Duet2 sporadically hunting for target temp

-

This may be a combination of some macro issues due to recent firmware updates as well as an intermittent connection near the hotend probe.

Thanks for the help. I am going to try to nail down the probe issue first to start to rule out some variables and make this easier to figure out.

-

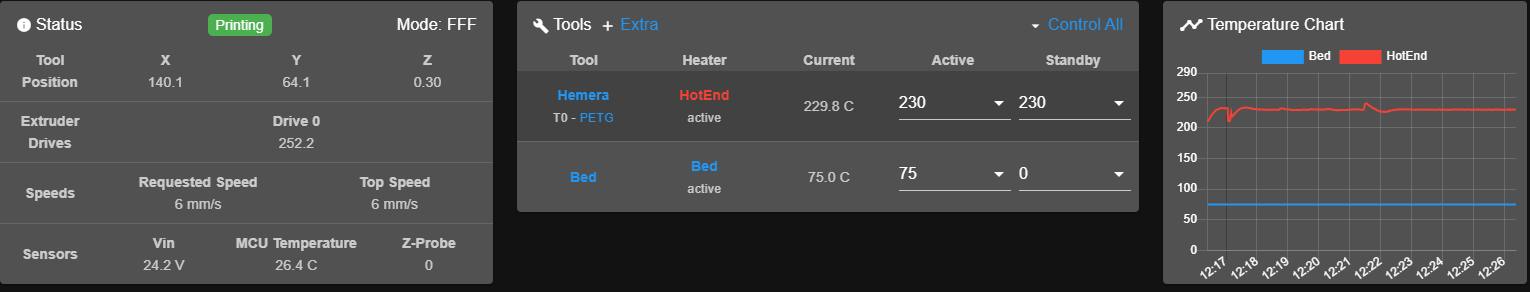

post a picture of the temperature graph

-

I am attempting to run a print right now. The blips in the graph are heater faults I have had to clear. The temp just seems to stay on and then drift, clear it, it works again. Not spikes to 2000 or anything like that.

-

those are spikes none the less.

this points to either noise in the pt100 cabling. try to isolate the cables from other cables especially motor cables.

-

The PT100 wire is not twisted pair. It is just a straight through cable. However, all of the motor cables are in fact twisted pair.

Is tearing this wire bundle apart and using twisted pair for the PT100 sensor a necessity? If that would eliminate this issue I have not problem doing it. But it is quite the task if it isn't usually necessary.

-

for now just run the wire separate and see if the problem persists.

-

@Veti Ok, doing that now. I know I read something somewhere about 4wire vs 2wire on the PT100. Right now I am just running a straight 2wire.

Running a separate twisted 2wire now.

-

Well, so far so good. I ran a twisted pair and terminated new connectors. One of the two seemed to have fixed this issue for now. Thanks for the help.

-

4 wire PT100 is the way to go if you can manage the wiring. I run a 4 wire setup with the two pairs twisted. It runs through a bundle with 2 fans, an extruder stepper, and the heater, for a meter and a half and it's been solid.

-

@mitch said in PT100 sensor on Duet2 sporadically hunting for target temp:

I recently changed to the E3D PT100 sensor and Daughterboard. The temps seem to be correct for the hotend but it has a hard time staying on temp. It seems to hunt around the target temp with a variance of about 0.1 - 0.9C even after a PID tune.

Regular oscillations about the target temperature when the print head is stationary suggest that the actual dead time of your hot end is higher than the M307 value. So try increasing the D parameter in your M307 command by about 25%.

Random fluctuations when the head is stationary are more likely to be caused by a bad connection, or by interference from stepper motor wires.