My Delta project

-

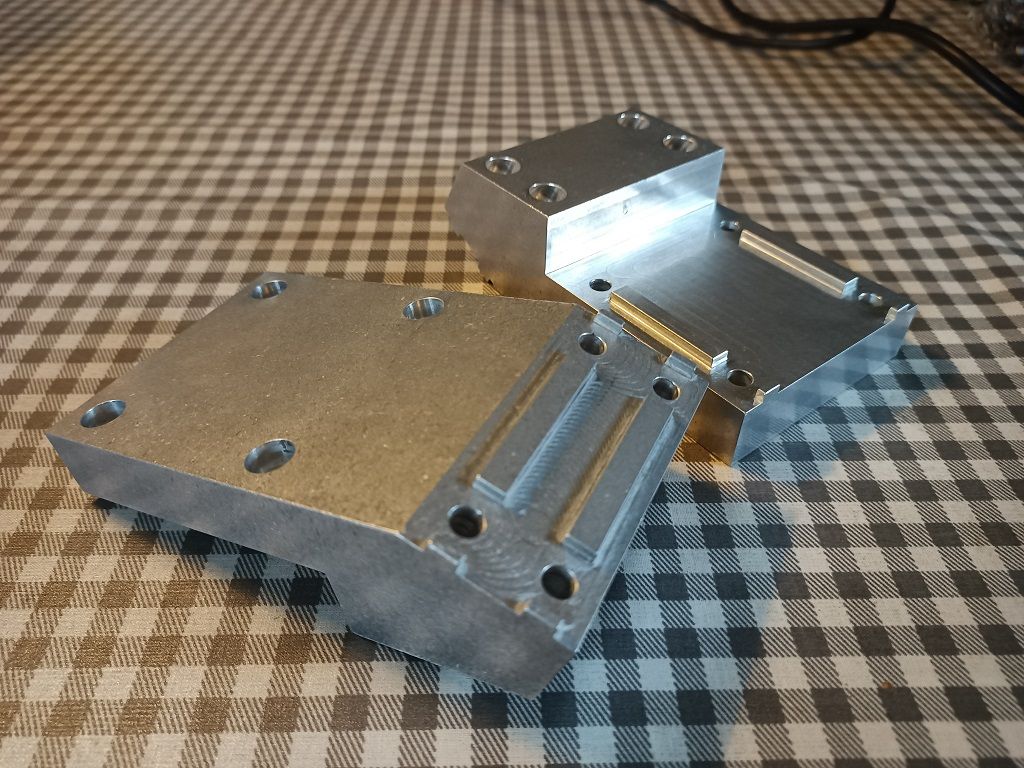

My current ongoing project is a large delta printer. Bed size is 510mm and the total height will be 1800mm. The goal is to have a very rigid design so I went with V-slot C-beam 40x80 for the towers and V-slot 20x80 between them. I could not find any suitable corners so I made my own design in Fusion 360 and my oldest son helped me to fabricate them with a CNC-milling machine at his work.

I have all the extrusions and all corners but so far nothing is assembled yet but I have some renderings and a photo.

-

Looks good! Keep us informed of progress.

-

Hi,

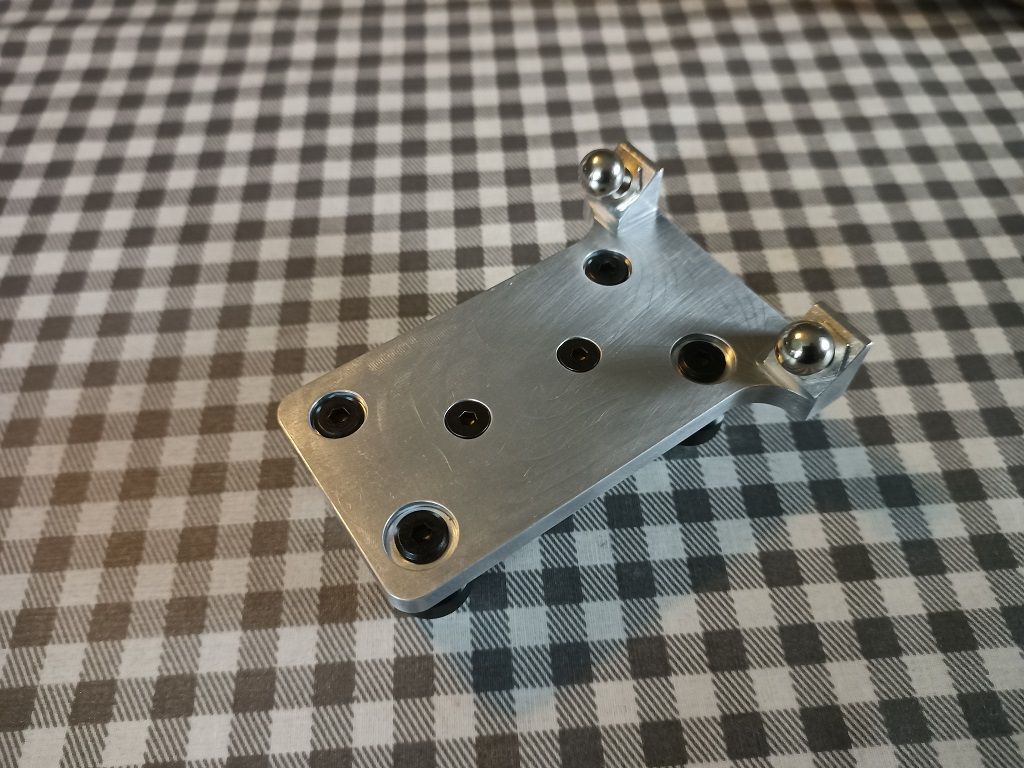

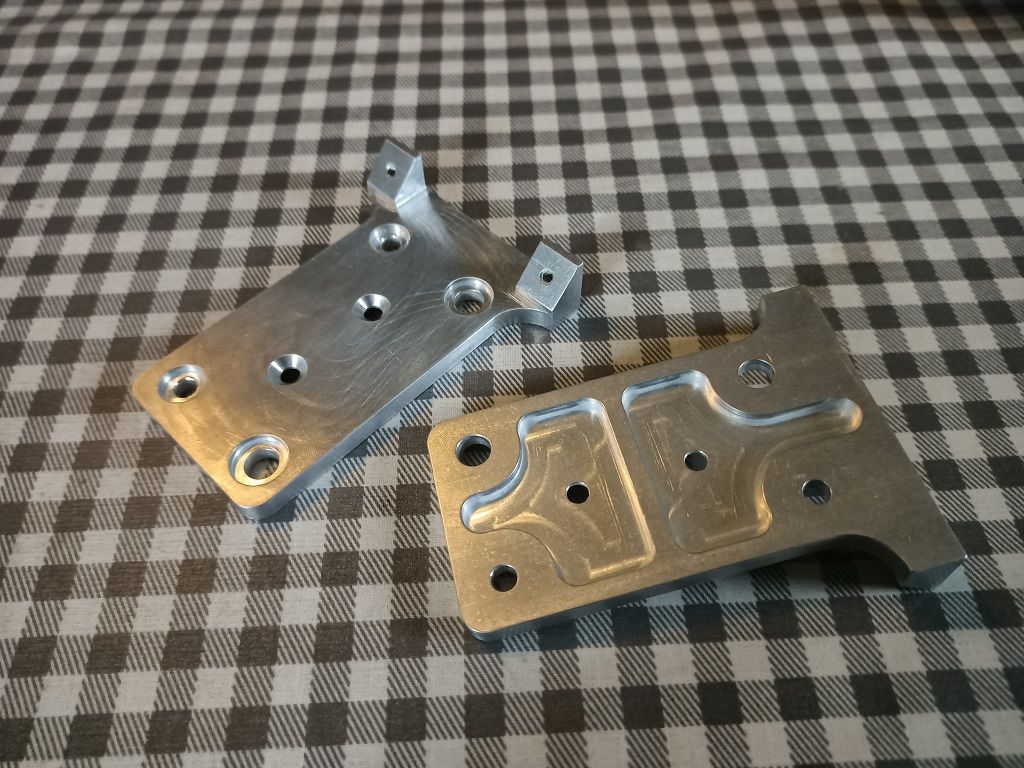

The progress for my project is slow but during this week I made some V-Slot gantry plates and belt clamps that fits the plate.

Edit: the clamp with teeth is bought.Also adding some photos of the extrusion corners that my son helped me to fabricate and a photo of the frame assembled. The corners fits the extrusions very well with slide fit (near press fit). I also fabricated some longer M6 T-nuts. The frame is very rigid.

Why I choose to fabricate in aluminum with CNC machines? I want to learn Fusion 360 for design and manufacture (post processing CNC program) and I have access to machines.