HELP! Duet 2 WiFi Configuration and DWC Upload???

-

Do I just change my M574 X2 Y2 to -X2 -Y2? or would that not work at all?

Or I can just start the whole setting up endstop process over again from scratch

-

-

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

1: After its done with a print it crashes into the front/left (that's the biggest reason)

Well the behaviour after the print is over should be controlled by the slicer end gcode. Please post a sliced gcode file so we can see what it's actually being commanded to do.

Have you updated the cura with the bed size we measured before and put in M208?

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

My home endstops are right there in the back/right corner

Endstop location can be at the high end or the low end. It doesn't really matter.

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

It's just a lot of wasted time and makes more sense to have it start the print at the corner that it's home at.

Prints are typically placed in the center, so the distance from one corner or the other should be the same. Do you mean it has to do a prime line first that's positioned at the opposite side? We can change the location of the prime line in the slicer start gcode.

But if you're really desperate to change it.

M574 X1 Y1 Z1 S1; change endstop from high end to low endChange the homing move directions

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat May 01 2021 17:31:12 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-240 Y-240 F3000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F6000 ; go back a few mm G1 H1 X-240 Y-240 F240 ; move slowly to X and Y axis endstops once more (second pass) G1 H1 Z-315 F240 ; move Z down stopping at the endstop G90 ; absolute positioning; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat May 01 2021 17:31:12 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-240 F3000 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X5 F6000 ; go back a few mm G1 H1 X-240 F240 ; move slowly to X axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioning; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat May 01 2021 17:31:12 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Y-240 F3000 ; move quickly to Y axis endstop and stop there (first pass) G1 H2 Y5 F6000 ; go back a few mm G1 H1 Y-240 F240 ; move slowly to Y axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90If you notice that after changing the directions that the axis is moving AWAY from the endstop instead of towards it, then change the rotation direction for the motor.

M569 P0 S1

M569 P1 S1 -

Ok. So.

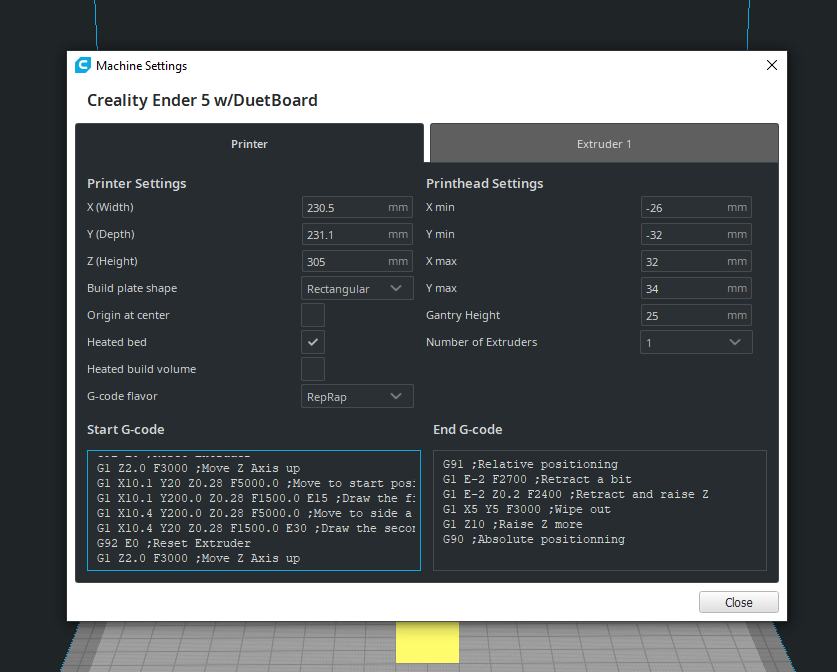

-Yes, the axis limits are set up in Cura (Ok, cool, we'll change the end gcode)

-Prints are typically placed in the center, so the distance from one corner or the other should be the same. Do you mean it has to do a prime line first that's positioned at the opposite side? We can change the location of the prime line in the slicer start gcode.- Yes it's starting the prime line at the opposite side and then at the end, homes to the opposite side

- So if that's the problem then yeah, I guess it would be in Cura. What lines would I have to change?

- I think it homes fine but if the Cura changes don't fix it, I'll change those homing move directions and endstops in the firmware.

Thanks,

-Carson

-

For the prime line, where do you want it to start and end? Physically jog the nozzle to where you want it to start and end, and make note to the XY coordinates, then we can place those in the prime line.

For the end gcode, I don't see anything that would be moving it a large amount at the end of the print. It looks like it should be doing a retraction and then a small 5mm diagonal move to wipe the nozzle and then raise it. Can you maybe make a video showing what it's doing at the end of the print?

-

@phaedrux

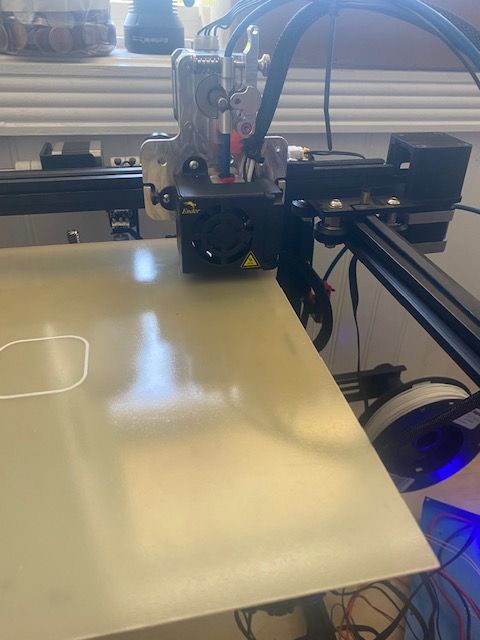

Videos for start and end of prints as they are currently

https://www.dropbox.com/sh/urqhwgr6phs2uty/AAC8QKXjih9UCh5PN5P1vy8ia?dl=0

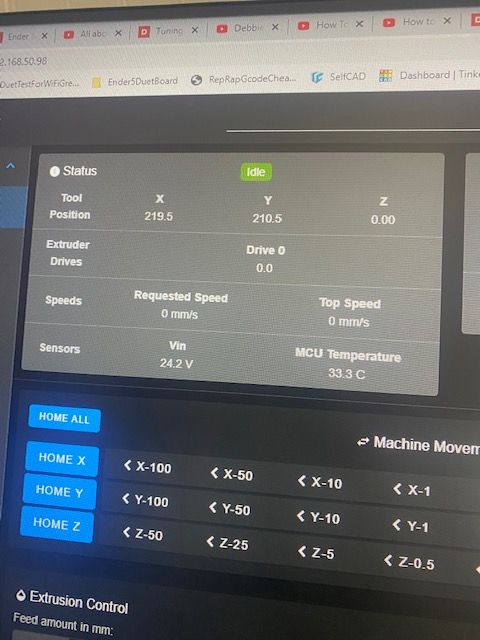

Picture of new coordinates for the start of the prime line

Picture of printer head position for new coordinates to be entered^

-

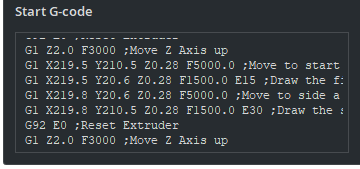

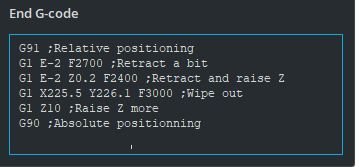

Here's what I plugged in (what I think it might be).

-I won't run anything until I get the okay from you. Just wanted to try and be proactive.

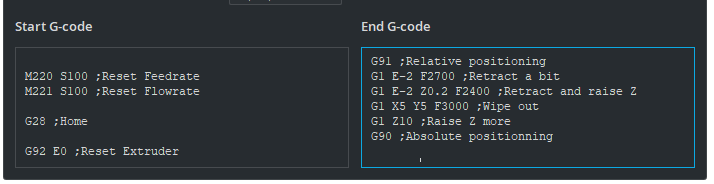

New Start G-code

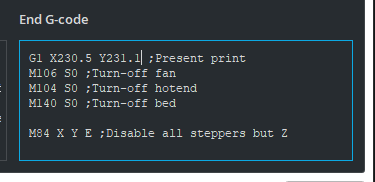

New End G-code 1 of 2

New End G-code 2 of 2

-

The prime line location looks good.

The end gcode has a problem though. You've changed the small wipe move of 5mm to a massive 230mm move. That's not what you want to happen.

The "present print" bit could be removed entirely. Is that below the first part? I hadn't see that before. That might have been what was causing the crashing. That move would make more sense for a cartesian i3 style printer with a bed that moves back and forth. The idea being that it will slide the bed forwards for you to get at the print. In this case you really just want the print head to move out of the way. The safest way to do that would be to replace

G1 230 Y230 ; present printwithG28 X Ywhich will just home the X and Y axis to get the print head out of the way. -

Yes, the second End G-code picture is below it when you scroll down

Ok. I've fixed a few things. Let's see how this is.

Start and End (Top Half)

Start and End (Bottom Half)

If all this looks good, I'll run another test print

Thanks,

-Carson

-

Yes that looks better.

-

Everything looks good. After I get home from work tomorrow, I'll do a few different tests, other than the cube and just check everything out to be sure.

Thanks again for all your help! I couldn't have done it without you!

-A very Grateful Printer, Carson

-

So I'm back.

3 questions.

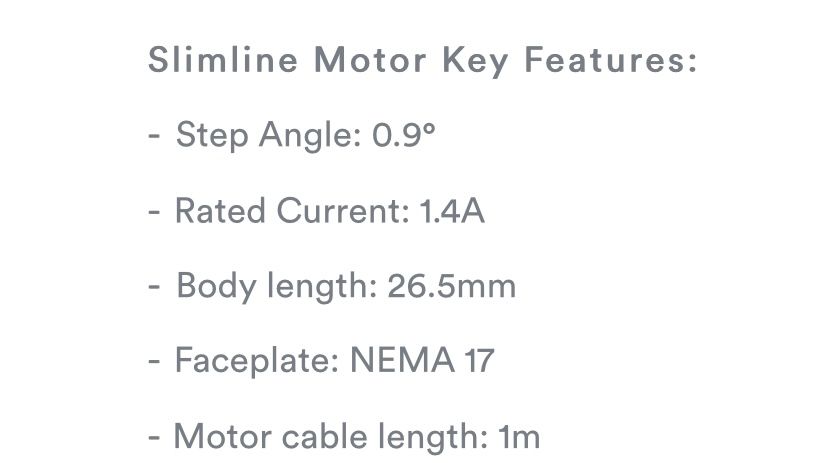

- I swapped my extruder stepper motor with a .9° pancake. What settings do I need to change in my config file?

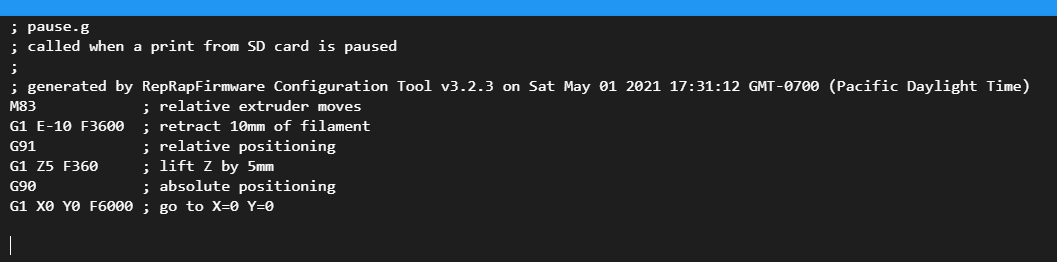

- When I pause a print it crashes into the front left corner. What do I need to change? the G90 command?

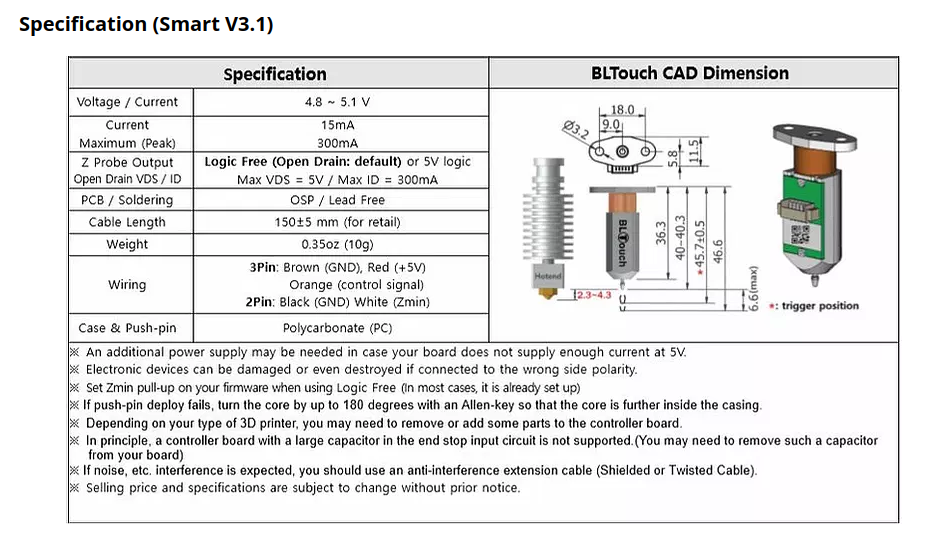

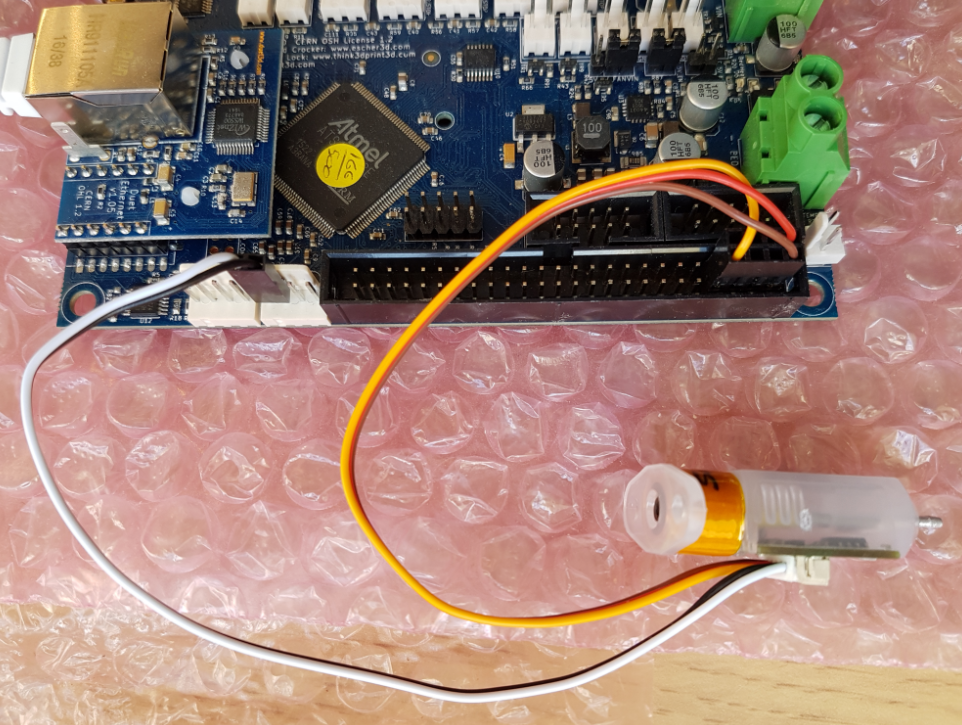

- I am ready to set up the BL Touch. How do I set it up in the config file? It's physically installed on the fan shroud, but I don't know what or if I need to set the offset. I also don't know where to plug it in on the duet. I have the Black and White wired to the Z Endstop. Where do I plug the yellow red and blue connector into?

ERROR

Something went wrong while parsing server response^ I keep getting this when I try and upload screenshots of my files. Until I get it fixed let me know what you need and I can relay the info.

Thanks,

-Carson

-

@phaedrux

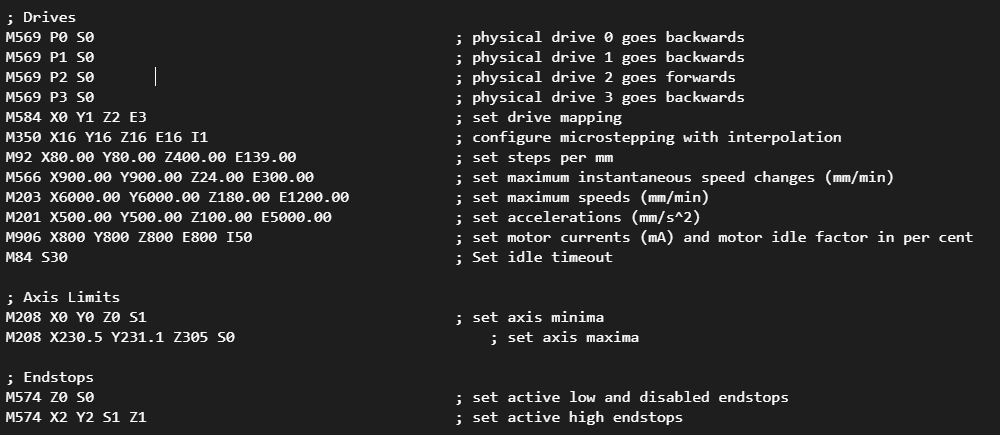

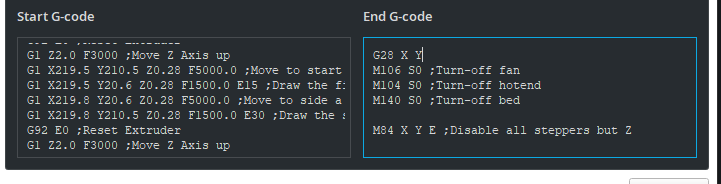

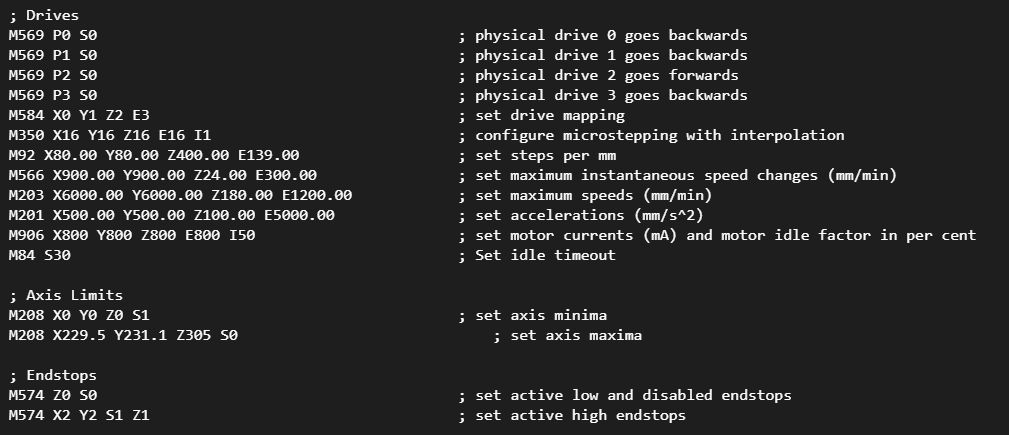

Fixed it. Here are screenshots of my files as they are currently set

-

For the extruder changing to 0.9 degree from 1.8 degree means that you would double your steps per mm. If you were already using a 0.9 motor you wouldn't change anything.

For your pause.g if it's hitting the edge you can slightly adjust the G1 X0 Y0 to be G1 X10 Y10 to give it some space. But if it can't safely reach x0 y0 then your M208 maxima might be a bit off.

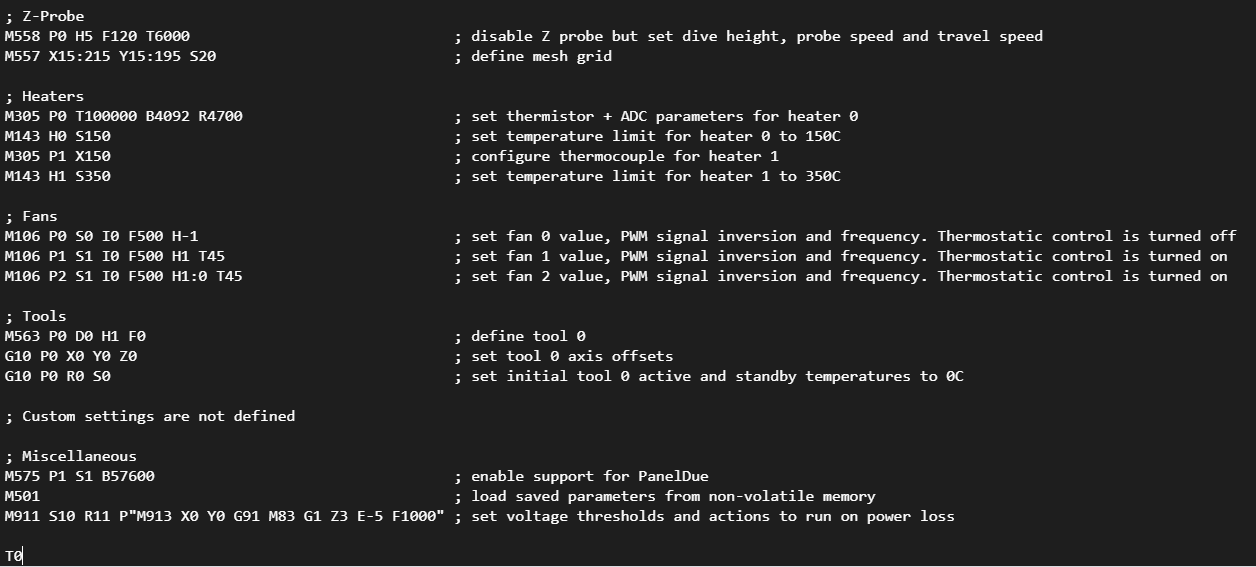

For the BLTouch you need this in config.g

; Z-Probe M307 H3 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch M558 P9 H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:195 S20 ; define mesh gridYou'll need to check config-override.g to any

M307 H3lines and delete them if they exist.And you'll need to create two macro files in the /sys folder for deploy and retract commands to control the pin.

; deployprobe.g ; called to deploy a physical Z probe ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat May 22 2021 10:19:48 GMT-0600 (Central Standard Time) M280 P3 S10 I1 ; deploy BLTouch; retractprobe.g ; called to retract a physical Z probe ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat May 22 2021 10:20:08 GMT-0600 (Central Standard Time) M280 P3 S90 I1 ; retract BLTouchFor wiring it up you should follow this:

-

When I was checking the new e-steps I noticed it was skipping so I tried to loosen/tighten the tension, and then I took out the filament and the same thing happened. Does this mean this particular motor doesn't have enough torque to support the extruder?

https://www.dropbox.com/s/dw34eyf572cj4vj/Skipping Motor.MOV?dl=0

-

Do you have to have the specs of the motor? It may need more current than the previous motor. The rule of thumb is to use ~60-80% of the rated motor current.

So if the motor is rated as 1amp (aka 1000ma) then you would use 600 to 800 ma in the M906 command to set the current.

-

-

Oh also should the tip of the BLTouch probe be at the same height as the tip of my nozzle in relation to the bed?

-

@pcnoobneedsmajorhelp No, or you risk crashing the BLT

IIRC the bottom of the main body of the BLT, not the probe should be 4-5mm higher than the nozzle -