Understanding Height Maps

-

@jsinicro said in Understanding Height Maps:

M671 X139.21:-120.26:139.21:-120.26 Y-101:-101:-101:-101 ; lead screws offsets from X0,Y0 homed nozzle position remember to dimention right tower later ; currently we are only using left tower which controller 1 and 4 where 4 is the back motor when facing power supply

I don't understand what you are doing.

What kind of printer have you created?

Perhaps a photo would clarify.

Thanks.

Frederick

-

@fcwilt I finally see a light at the end of the tunnel. One spot I did not have enough glue however for the most part it looks good. I had to manually adjust the the bed with the bed springs as I was noticing almost touching the bed in some areas here is a pic of the leveling_nozzle stl. Its a custom build printer with OpenBuilds structural parts.

![IMG_2287[1].jpg](/assets/uploads/files/1625932568701-img_2287-1-resized.jpg)

![IMG_2288[1].jpg](/assets/uploads/files/1625932578402-img_2288-1-resized.jpg)

-

@jsinicro This is a prototype.

-

@jsinicro The idea came from the Zydex youtube video but I needed something much larger.

-

@jsinicro said in Understanding Height Maps:

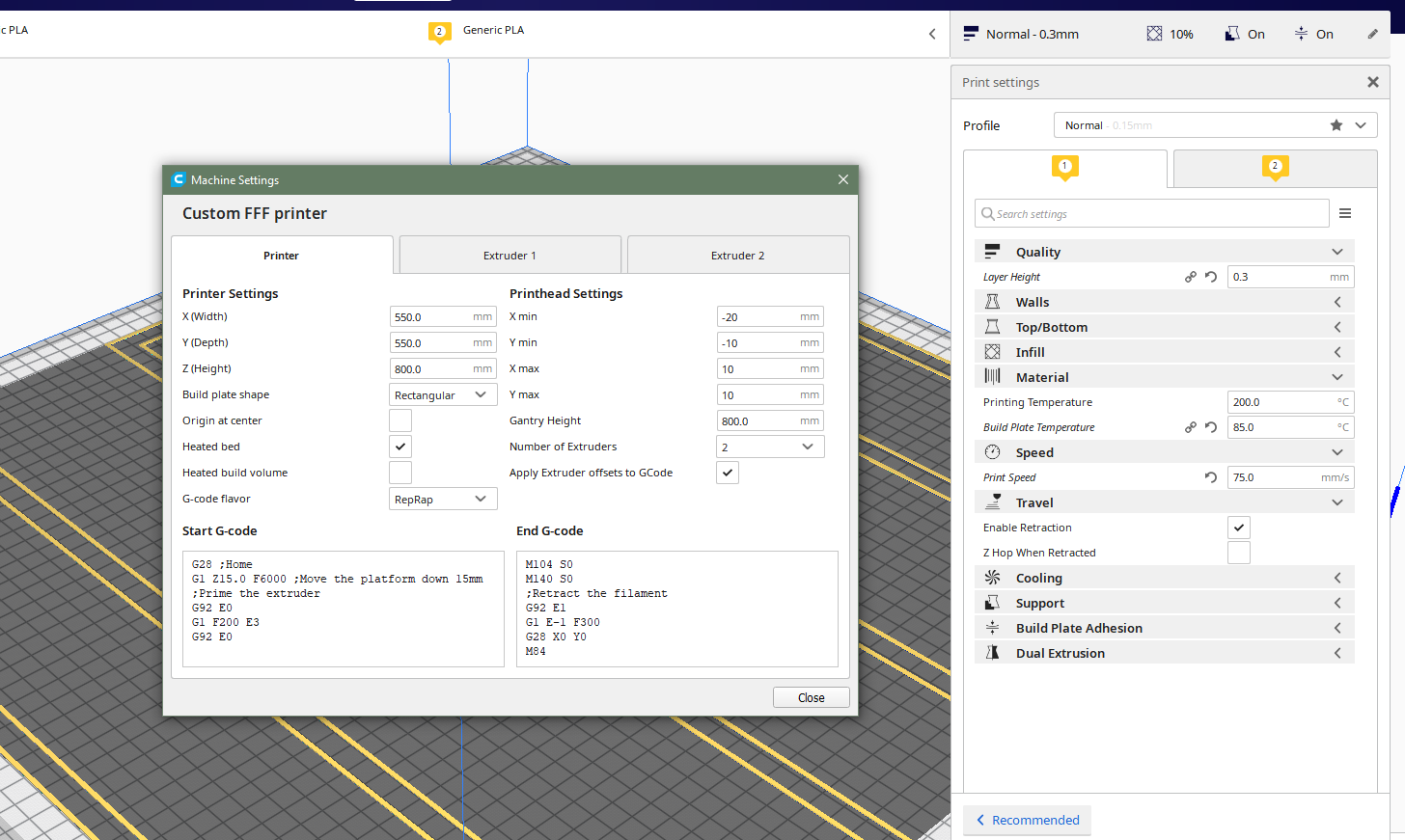

I used Cura the latest version and used the default settings to slice it. The print started but it was sitting there at the beginning not doing anything

Check your cura start gcode for any commands that set speed, accel, and jerk values. If they are there, remove them, and make sure you're set to use reprap gcode flavor.

-

@phaedrux You mean like M203,M205,M220,M566, OK you said in Cura, Like remove print speed or set it to 0? G-code flavor is set to RepRap.

Is there a better slicer program that is more specific to Duet 3 boards or RepRap ?

-

Interesting.

So you have two sets of Z towers with two steppers?

Can the Y axis move enough so both X and U can reach the entire bed?

Never tried to configure such a printer.

I think you will need to setup auto level for X and Y and run the process, then setup for U and Y and run the process.

Frederick

-

@jsinicro said in Understanding Height Maps:

Is there a better slicer program that is more specific to Duet 3 boards or RepRap ?

No, Cura is fine. Depending on the starting printer profile it will be setup for marlin and might have some speed commands specific to a different printer. Looks like yours is fine though.

-

@phaedrux The print was going so well but then looked like it was printing over the same extruded line and on one side the extruded plastic lifted up so it messed up. I'll try again

-

@jsinicro Maybe I needed more glue. This is a glass top I've bee using glue stick. the nozzle is set to 200 the bed is set to 85 for PLA. The nozzle is cooled via the Aqua cooled, however I do not have a blower yet for the extruded plastic That's what I am trying to print first. I've seen a bunch of videos that printing with a blower or with out one there isn't much difference.

-

Is the glass right on top of the bed heater?

Is it getting evenly hot? 85c is pretty hot for PLA.

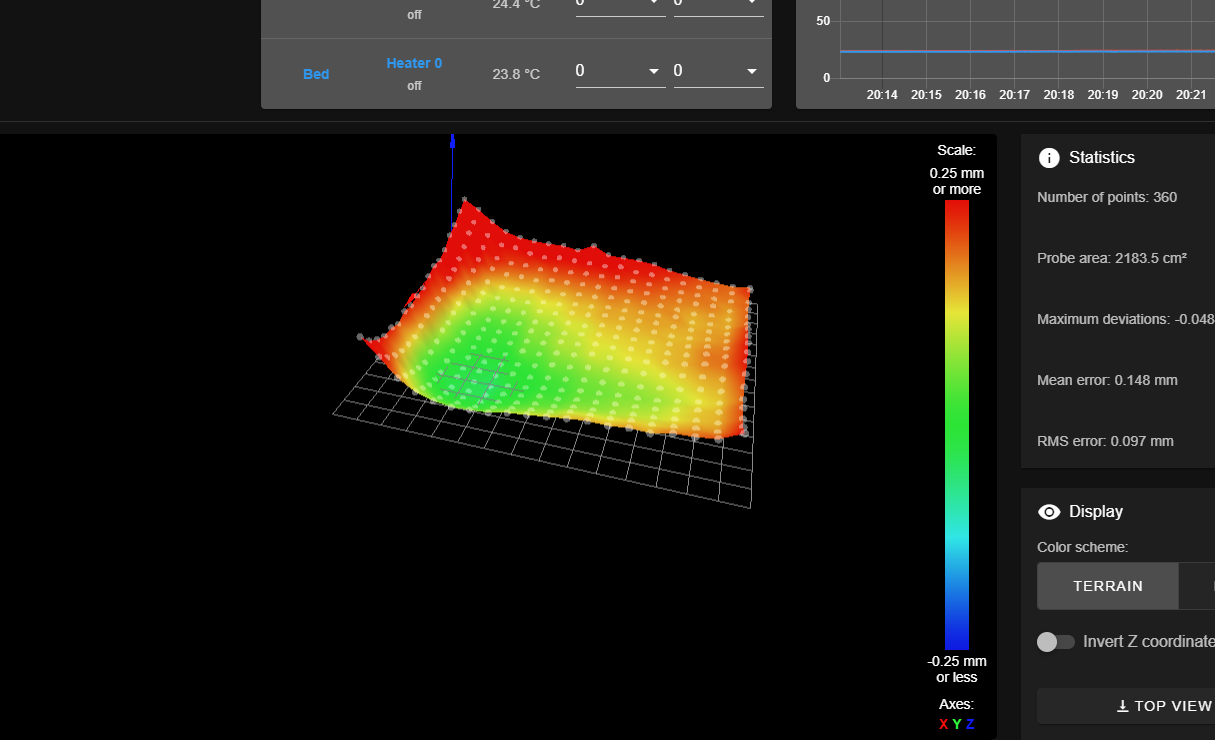

Have you run a recent G29? What does the heightmap look like?

-

@phaedrux The bed gets really hot, I could probably cook on it, the heat gets distributed evenly but its definitely hotter towards the middle. Its one peace directly on the glass with cork under it. Its the same type of glass used on stoves, custom cut.

I ran the G29 after I created the bed auto level macro in the bed.g I issue the G32 at the end of the homeall.g and then the G29. I posted that map in my other post the third one. It did not make that much difference. The pic in that post that I was seeing the light at the end of the tunnel came out decent in the beginning but then I had to pause the print as one side started becoming loose. To get to that print as the pic showed in the other post I was adjusting the nozzle height manually as I was watching it move. Not doing so the nozzle would get way to close to the bed and only extrude like a spider web. I did not load the map with that print. The map showed about 1mm difference on the points not sure why it comes out almost on a 60degree. I will run the G29 again and see if there's any difference.

-

@fcwilt Yes, both X axis can travel the full length of the Y axis bed. Currently I am focusing on getting one tower at a time to generate a relative good print, then I will try to get the other tower to do the same with different filament.

-

-

@fcwilt Your welcome, Still trying to figure out why the auto level when it moves to the first point keeps hitting the end stop, it stops once the Y axis hits the limit swatch, but the X axis limit switch lights up but the motor keeps turning till the Y axis stops.

-

Given you can only level the X gantry using two Z steppers I think you should try using these points:

- X1 = Xmin + absolute(probe X offset)

- X2 = Xmax - absolute(probe X offset)

- Y1 = ( (Ymax - absolute(probe Y offset) - (Ymin + absolute(probe Y offset) ) / 2

- Y2 = Y1

M671 X1:X2 Y1:Y2 S5

That should insure that both points probed keep the nozzle at valid positions.

Frederick

-

@fcwilt Wow, here's the latest map just finished.

-

-

@fcwilt OK, thanks, I will try that. Looking at at the calculations I measured the leadscrew to the nozzle not to the probe. That's probably why it keeps hitting the endstop.

Also, The bed is supported by 2 1/8" 29.1/2"x29.1/2" aluminum sheets. The bottom sits on the center of the 2 Y axis gantries and in between the 2 sheets I have the springs -medium strength, so that I can adjust the leveling. I recently just added this I thought I could get away with out it.

-

@jsinicro: Just to make sure by absolute you mean like the abs() function correct?