Using Accelerometer for Input Shaping

-

Hey, so i got finally my accelerometer running on my 3D Printer. I can run tests and collect the data and look at them. But what now? How can i use this data to use Input Shaper on my Printer. In the documentation nothing about this is listet at the moment.

-

Configure the input shaper and do some test prints.

https://duet3d.dozuki.com/Wiki/Gcode#Section_M593_Configure_Input_Shaping

A ringing test print works well and you can change the shaper being used every several layers on the fly by sending a new M593.

-

@phaedrux thank you for the quick answer, i will test it out

-

I've updated the Input Shaping page with my previous post since it doesn't really get mentioned anywhere else as far as I found.

https://duet3d.dozuki.com/Wiki/Input_shaping

https://duet3d.dozuki.com/Wiki/Accelerometers

The documentation is a little light at the moment and will improve as the feature is further developed. Please feel free to share any suggestions or questions to help us improve it.

-

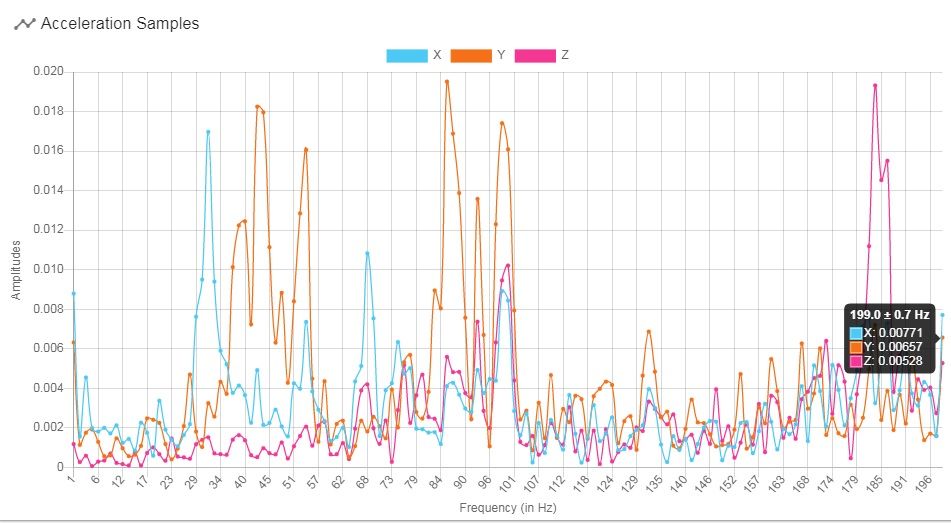

@phaedrux it would be good to know on how to correctly analyze the data i now gotten. Date for X Axis looks something like this

but which frequency should i now try to cancel out, like the 7hz one or more like the 43hZ one?

but which frequency should i now try to cancel out, like the 7hz one or more like the 43hZ one? -

@staticred 42-43 your machine shakes a lot here is mine for both X Y, it is a big machine with all metal parts and hemera. The carriage is about 1.5 kg

-

@martin7404 what speeds did you use for the testings? I used 30000mm/min to test it. My normal printing speed at around 10000mm/min has kind of the same readings as yours. But my machine is also at the moment super small and the carriage ways about 300g.

-

@staticred 24000