Source of "Error: no tool selected"

-

@fcwilt Sent again -

-

@kb58 said in Source of "Error: no tool selected":

A print is started

Can you share the sliced gcode file?

@kb58 said in Source of "Error: no tool selected":

G30 s-1

Why do you have G30 S-1 in your bed.g?

G30 S-1 ; Probe the bed at the current XY position. When the probe is triggered, do not adjust the Z coordinate, just report the machine height at which the probe was triggered.

-

@kb58 it's probably some command in your print files that the slicer generates before it adds your start script. Post the start of the GCode file excluding any large comment blocks.

-

@kb58 said in Source of "Error: no tool selected":

@fcwilt Sent again -

They are not coming through for some reason.

Frederick

-

@fcwilt it's probably simpler to extract the first 50 or so lines using an editor and post them here.

Some email systems don't allow .zip attachments.

-

@dc42 Good morning!

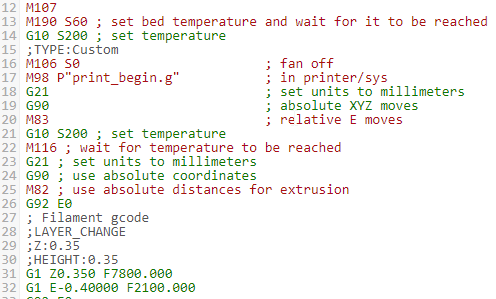

Okay, here's the first chunk of the PrusaSlicer-generated Gcode:

-

@phaedrux said in Source of "Error: no tool selected":

@kb58 said in Source of "Error: no tool selected":

G30 s-1

Why do you have G30 S-1 in your bed.g?

G30 S-1 ; Probe the bed at the current XY position. When the probe is triggered, do not adjust the Z coordinate, just report the machine height at which the probe was triggered.

A popular question, hah. Since it's a custom built printer, it's there just to offer reassurance that the probe trigger height remains consistent (bad experience with previous inductive probe). Once it's proven so, that line of code will be removed.

-

@kb58 It's the G10 S200 line at the top. It should be inserted after your print_begin.g macro.

-

@chrishamm Nicely done, sir!

If that line of code is slicer-generated, how would I move it, other than manually?

(I realize that this has moved outside the scope of Duet products, so I won't keep going on and on about it.)

Thank you very much for catching this. It wasn't a big problem, but a very nagging one!

-

@kb58 In my case it is sufficient to put T0 at the beginning of my Start G-code in PrusaSlicer v2.3.0, then the G10 code is generated below.

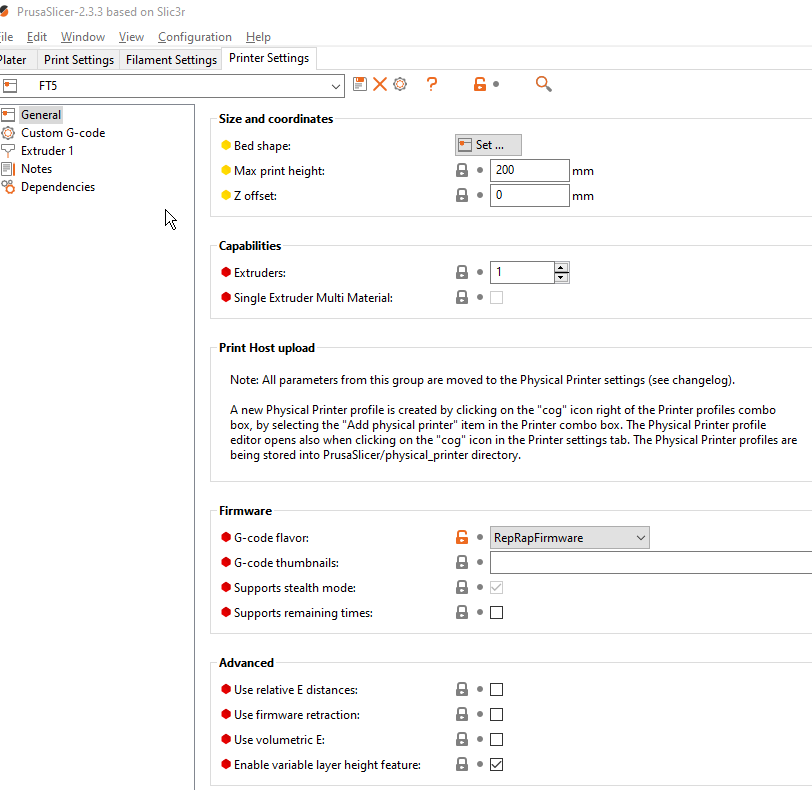

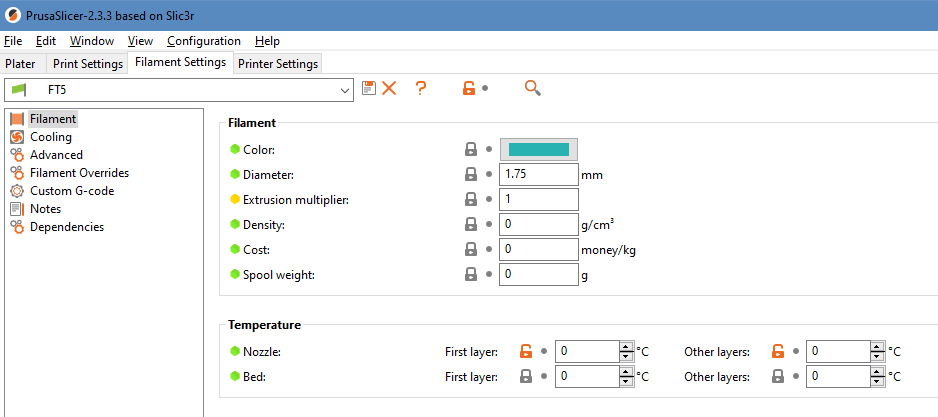

PS: I just noticed I still have Marlin compatibility set in PrusaSlicer and not RepRapFirmware. If I change to RepRapFirmware I get the same message.

-

@kb58 said in Source of "Error: no tool selected":

If that line of code is slicer-generated, how would I move it, other than manually?

Did you specify temps in the slicer?

Recall the conditions I specified for using Prusa:

When you do that this is Prusa generated code - no temp commands and thus no problems with the tool not being activated.

; PrusaSlicer (RepRapflavor - no temps) inserts the following around the call to this file ;M107 ; fan off (should be M106 S0) ;M98 P"print_begin.g" ; invokes this file ;G21 ; set units to millimeters ;G90 ; absolute XYZ moves ;M83 ; relative E moves Frederick

-

@fcwilt Okay, thank you, now I understand more clearly. So (in your setup at least), you have the printer set most parameters before starting a job, and reduced your slicer's "contribution" to the job to just be the object shape.

-

@kb58 See my updated comment. I just searched a bit and found this. I can confirm that once I change my start G-code to

T0 ; select first tool G10 P0 S[first_layer_temperature] M140 S[first_layer_bed_temperature] M116 ; wait for all temps to be reached the final G-code is correct and no error message can be seen.

-

@kb58 said in Source of "Error: no tool selected":

@fcwilt Okay, thank you, now I understand more clearly. So (in your setup at least), you have the printer to set most parameters before starting a job, and reduced your slicer's "contribution" to be the bare minimum.

Exactly.

The settings I mentioned are required to make it work.

I previously experimented with the slicer settings of S3D, CURA and PRUSA to find those settings that minimized the code the slicer generated to eliminate any conflicts like you encountered.

Which is why I had them appear at the beginning of my print_begin.g to remind me so I wouldn't forget to set them in the slicer.

At 71 forgetting is one of my new skills.

Frederick

-

@fcwilt Okay, thanks. This relates to my earlier comments about not knowing "who wins" as far as applying settings. Prusa sets temperature and other filament-related variables, yet, so can the printer/Duet code, so it was confusing about who's driving the bus, so to speak. Your configuration makes it clear that the Duet code applies all pertinent settings.