Unofficial 3.4 Maestro Beta: Extruder Drive Issue

-

Hey @dc42 I just flashed the unofficial beta build to give IS a shot on my Maestro, but didn't get to test it yet.

With IS and PA disabled, it was evident that the extruder drive wasn't functioning correctly. Even my prime line misbehaved with a pulsing extruder action, and high pitch whine from that stepper. Once the print started (a simple spiral vase square box), it continued to make high pitch "chirpy" sounds from the extruder stepper, and didn't push much plastic at all.

Stepper analyzer shows some definite weirdness:

Video of stepper: https://photos.app.goo.gl/w7nxsWg2BnRwjP9b6

M122 below. Let me know if I can gather anything else useful for you.

=== Diagnostics === RepRapFirmware for Duet 2 Maestro version 3.4.0beta2+ (2021-08-13 08:58:33) running on Duet Maestro 1.0 Board ID: 08DJM-956DU-LLMS4-7J9F6-3SN6Q-KBM2Q Used output buffers: 1 of 24 (24 max) === RTOS === Static ram: 23572 Dynamic ram: 69288 of which 0 recycled Never used RAM 18004, free system stack 158 words Tasks: NETWORK(ready,30.5%,262) ACCEL(notifyWait,0.0%,347) HEAT(notifyWait,0.1%,341) Move(notifyWait,0.1%,315) TMC(notifyWait,1.4%,117) MAIN(running,67.9%,459) IDLE(ready,0.0%,30), total 100.0% Owned mutexes: === Platform === Last reset 00:16:33 ago, cause: software Last software reset at 2021-08-11 20:47, reason: User, GCodes spinning, available RAM 19744, slot 2 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x04 Step timer max interval 1866 MCU temperature: min 41.2, current 42.7, max 49.0 Supply voltage: min 24.0, current 24.3, max 24.4, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/0, heap memory allocated/used/recyclable 2048/24/24, gc cycles 0 Driver 0: position 0, standstill, read errors 0, write errors 1, ifcnt 178, reads 34263, writes 9, timeouts 0, DMA errors 0 Driver 1: position 0, standstill, read errors 0, write errors 1, ifcnt 246, reads 34263, writes 9, timeouts 0, DMA errors 0 Driver 2: position 5880, standstill, read errors 0, write errors 1, ifcnt 188, reads 34263, writes 9, timeouts 0, DMA errors 0 Driver 3: position 0, standstill, read errors 0, write errors 1, ifcnt 155, reads 34263, writes 9, timeouts 0, DMA errors 0 Driver 4: position 0, standstill, read errors 0, write errors 1, ifcnt 62, reads 34266, writes 6, timeouts 0, DMA errors 0 Driver 5: position 0, assumed not present Driver 6: position 0, assumed not present Date/time: 2021-08-13 14:24:01 Slowest loop: 546.35ms; fastest: 0.10ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 10.0MBytes/sec SD card longest read time 1.3ms, write time 152.1ms, max retries 0 === Move === DMs created 83, segments created 32, maxWait 737474ms, bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves 464, completed moves 464, hiccups 108748, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1, chamberHeaters = -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Network === Slowest loop: 478.23ms; fastest: 0.02ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 Interface state active, link 100Mbps full duplex -

@ccs86 what pressure advance setting are you using?

-

@dc42 said in Unofficial 3.4 Maestro Beta: Extruder Drive Issue:

@ccs86 what pressure advance setting are you using?

Zero at the moment.

Here's my full config:

config.g.txt -

@ccs86 I think i hit the same bug but on a duet2 wifi running the latest beta. It seems that high pitch is starting when printing lines considered "bridges" from prusa slicer at the first layer that was at 0.13mm (variable layer height print). Also i notices some more clicking on other test print i was doing as per previous beta build. I get nothing when issue M122 on that firmware.

Video of the issue (starts at around 0:50):

Youtube link

Gcode:

Spool.gConfig.g:

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.9 on Sat Nov 28 2020 11:28:36 GMT+0100 (Ora standard dell’Europa centrale) ; General preferences G21 G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Voron 2.4" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; PanelDue M575 P1 S1 B57600 ; --- drive map --- ; _______ ; | 6 | 7 | ; | ----- | ; | 5 | 8 | ; ------- ; front ; Drives M569 P0 S1 ; A M569 P1 S1 ; B M569 P3 S1 ; Extruder M569 P5 S1 ; Z1 M569 P6 S0 ; Z2 M569 P7 S1 ; Z3 M569 P8 S0 ; Z4 M584 X0 Y1 Z5:6:7:8 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E419.50 ; set steps per mm M906 X800 Y800 Z1000 E800 I75 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ;M566 X1500 Y1500 Z60 E16000 ; Set maximum instantaneous speed changes (mm/min) ;M203 X18000 Y18000 Z3000 E20000 ; Set maximum speeds (mm/min) ;M201 X3000 Y3000 Z250 E4000 ; Set maximum accelerations (mm/s^2) M566 X600 Y600 Z600 E8000 ; Set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z6000 E15000 ; Set maximum speeds (mm/min) M201 X20000 Y20000 Z1500 E1800 ; Set maximum accelerations (mm/s^2) M204 P1500 T2000 ; Set printing acceleration and travel accelerations ; Axis Limits M208 X3:350 ; set axis minima/maxima M208 Y0:350 M208 Z0:330 ; Endstops M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop M574 Z1 S1 P"zstop" ; configure active-high endstop for low end on Z via pin zstop ; Z-Probe ;M558 P5 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to switch and the dive height + speeds ;G31 P500 X0 Y25 Z2.5 ; set Z probe trigger value, offset and trigger height ; Heaters M308 S0 P"bedtemp" Y"thermistor" A"Piatto" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 R0.703 C465.2 D4.17 S0.65 V23.9 B0 ;PWM max @65% ;M307 H0 R0.636 C552.9 D5.58 S1.00 V23.9 B0 PWM max @ 100% M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"spi.cs1" Y"rtd-max31865" R430 ;PT100 ;M308 S1 P"e0temp" Y"thermistor" A"Estrusore" T100000 B4725 C7.06e-8 ;B4138 originale E3D ;M308 S1 P"e0temp" Y"thermistor" A"Estrusore" T100000 B3950 ;NTC CINESE M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P0 S0 H-1 C"Layer" ; set fan 1 value. Thermostatic control is turned on M950 F1 C"fan0" Q32000 ; create fan 0 on pin fan0 and set its frequency M106 P1 S255 H1 T45 C"Hotend" ; set fan 0 value. Thermostatic control is turned off M950 F2 C"fan2" Q100 ; create fan 0 on pin fan0 and set its frequency M106 P2 S0 H0 T50 C"Elettronica" ; set fan 0 value. Thermostatic control is turned off M950 F3 C"e1heat" ; create fan 0 on pin fan0 and set its frequency M106 P3 S0 H-1 C"Luci" B0 L0 ; set fan 0 value. Thermostatic control is turned off M950 F4 C"duex.fan3" Q32000 ; create fan 1 on pin fan1 and set its frequency M106 P4 S0 H-1 C"LayerBIG" ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; NPN Z-Probe M400 M558 P8 C"zprobe.in" F1200 H5 A5 S0.01 B0 R0.2 T25000 G31 T8 P500 X0 Y25 Z0.665 ; inductive probe offset, not critical, only used for coarse homing ; Z tower positions M671 X-65:-65:365:365 Y-20:380:380:-20 S20 ; Define Z belts locations (Front_Left, Back_Left, Back_Right, Front_Right) M557 X10:340 Y0:300 P10 ;Taper height M376 H10 ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ;Accelerometer M955 P0 C"spi.cs5+spi.cs6" I50 ; Input Shaping M593 P"zvdd" F58.4 ;M593 F50 ;Firmware retraction M207 S1.5 F3600 Z0.2 ;Full Lights on at startup M106 P3 S1.0 T0 filament.g:

;M592 D0 A0.001692599 B-0.000105515 M572 D0 S0.045 -

Any other data that I can gather to help with this?

-

@ccs86 said in Unofficial 3.4 Maestro Beta: Extruder Drive Issue:

Any other data that I can gather to help with this?

Yes, you've already provided your config.g file but please also provide a print file that demonstrates the problem.

-

@dc42 said in Unofficial 3.4 Maestro Beta: Extruder Drive Issue:

@ccs86 said in Unofficial 3.4 Maestro Beta: Extruder Drive Issue:

Any other data that I can gather to help with this?

Yes, you've already provided your config.g file but please also provide a print file that demonstrates the problem.

The issue was evident even in my prime line:

G1 X10 Y0 Z.3 F2000 G1 E0 F2000 G1 X50 E5 F1200 G1 X135 E11 F1200 G1 X145 F800 -

@ccs86 please try the updated build at https://www.dropbox.com/sh/cq7q3g8coymo9s3/AABtPYEzV1_unETpKEMPInSia?dl=0.

-

@dc42 said in Unofficial 3.4 Maestro Beta: Extruder Drive Issue:

@ccs86 please try the updated build at https://www.dropbox.com/sh/cq7q3g8coymo9s3/AABtPYEzV1_unETpKEMPInSia?dl=0.

Awesome, working beautifully so far!

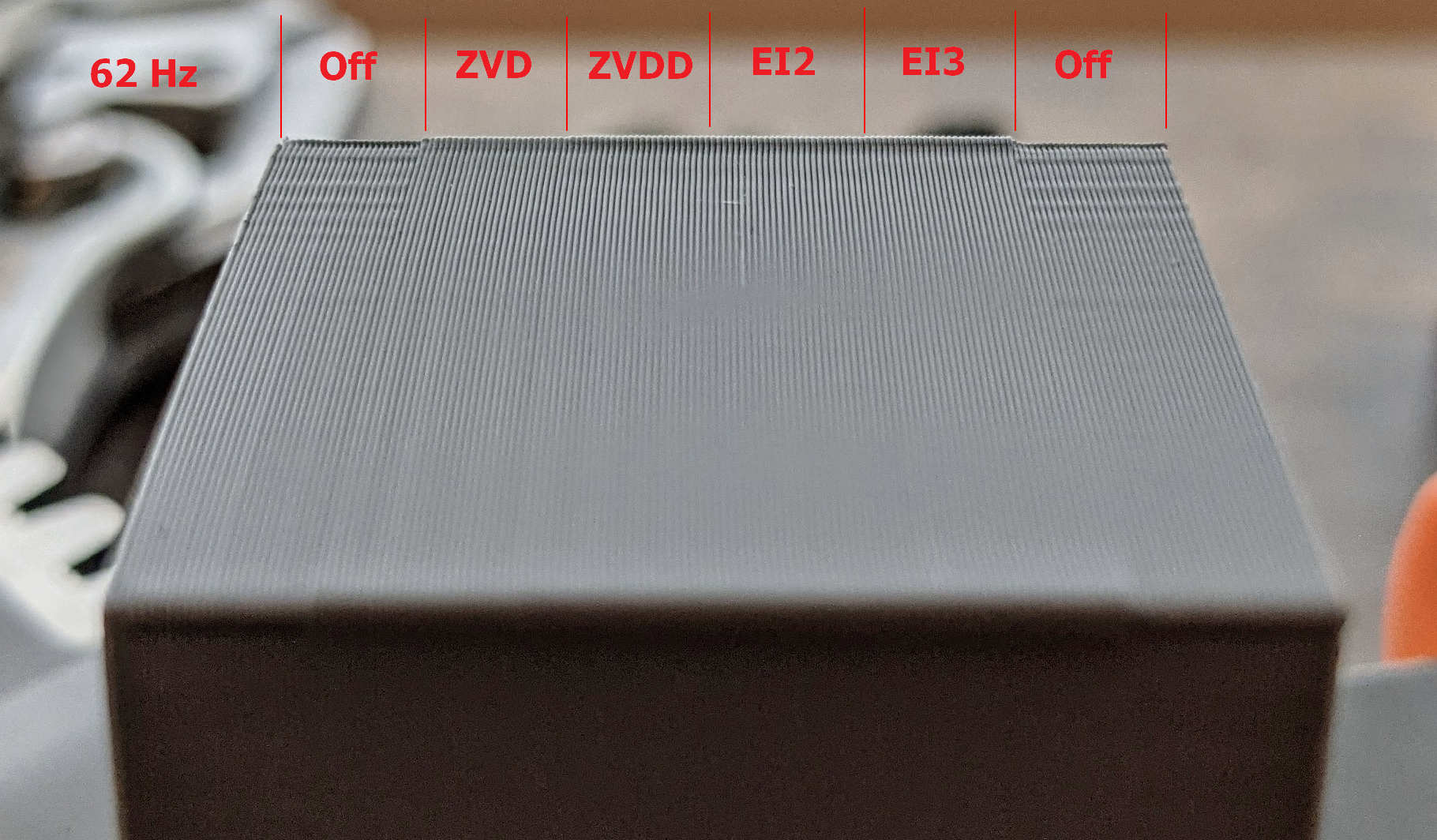

Very simple first test: 30x30x30 square, 3 perimeters, 80 mm/s, 10k accel, 12 jerk

All shapers seem highly effective at cancelling the ringing. But all visibly slow the effective acceleration a lot and cause significant corner bulge. I would love to be able to just tune that out with PA, but have found the current implementation very ineffective on my bowden printer.