BL Touch Installation what is Servo Pin?

-

I dont see S or A on the 558?

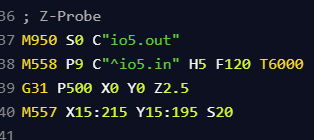

M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"io7.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:195 S20 ; define mesh grid -

@signpostman said in BL Touch Installation what is Servo Pin?:

I dont see S or A on the 558?

M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"io7.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:195 S20 ; define mesh gridWell that is curious. The default value for A is 1 - so 1 touch of the deployed pin on the BLTouch should have been enough to end the probing.

So that suggests that the firmware is not seeing the signal from the BLTouch.

Can you verify there is continuity on the white wire from the BL Touch to io7.in?

Frederick

-

@fcwilt I verified the continuity, but just to eliminate the wire length I put a short wire on the white. What is now happening is when homing the probe (on my desk) can be triggered over and over, eventually it stops. Could I insert the S parameter to see if it has any effect? where does it go?

-

@signpostman said in BL Touch Installation what is Servo Pin?:

@fcwilt I verified the continuity, but just to eliminate the wire length I put a short wire on the white. What is now happening is when homing the probe (on my desk) can be triggered over and over, eventually it stops. Could I insert the S parameter to see if it has any effect? where does it go?

The S parameter by default is 0.03.

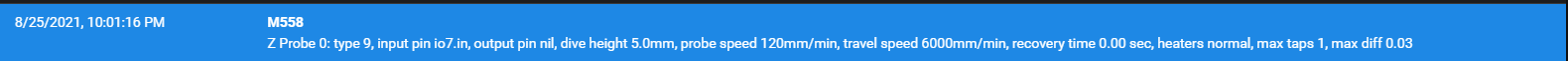

From the DWC Console you can execute M558 by itself and it will report the current settings.

For example from my printer:

Notice the last two value:

- max taps - that is the A parameter value

- max diff - that is the S parameter value

You can add the A and/or S parameter(s) to your current M558 command and set them as desired.

Frederick

-

-

-

@signpostman said in BL Touch Installation what is Servo Pin?:

@fcwilt Mine is set at Max Taps 1, also my Z Probe is set at io7, yours is at zprobe.in (are you on a duet 2?)

On that printer, yes, it is using a Duet 2 WiFi board but I also have two others printers using a Duet 3 Mini.

My recovery is set at 0 sec. could this be a problem?

I don't know for sure - I think it was @Phaedrux that suggested I use 0.2.

Nothing to be lost by changing the setting.

Frederick

-

@fcwilt How do I input that command?

-

@signpostman said in BL Touch Installation what is Servo Pin?:

@fcwilt How do I input that command?

I'm guessing that command is in your config.g file.

If it is you just edit the file, make the change, save the file and let the DWC reboot the printer when it asks to.

Frederick

-

@fcwilt will try in the morning, thanks for your help

-

@signpostman said in BL Touch Installation what is Servo Pin?:

I have the Z Endstop still mounted to the z axis. and the BL Touch is wired but setting on the bench. If I ask the machine to Home Z, The Z axis will lower and touch, triggering the endstop, then stop moving. if I then trigger the BL Touch, the Z Axis will descend again and trigger the Z Endstop again.

Does this give any clues of the issue?

; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.3.0 on Sat Aug 21 2021 12:06:11 GMT-0400 (Eastern Daylight Time) G91 ; relative positioning G1 H2 Z10 F6000 ; lift Z relative to current position G1 H1 Z-309 F2500 ; move Z down until the endstop is triggered G1 H2 Z5 F6000 ; go back a few mm G1 H1 Z-20Y F180 ; move slowly to Z axis endstops once more (second pass) ;G92 Z0 ; set Z position to axis minimum (you may want to adjust this) G30 ; probe bed ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 Z20 F2500 ; lift Z relative to current position G90 ; absolute positioningG1 H1 Z-309 F2500 ; move Z down until the endstop is triggered

G1 H2 Z5 F6000 ; go back a few mm

G1 H1 Z-20Y F180 ; move slowly to Z axis endstops once more (second pass);G92 Z0 ; set Z position to axis minimum (you may want to adjust this)

{1}

G30 ; probe bedIt's homing using the endstop with G1 H1 Z moves, and then it's got a G30 command at the end to use the probe.

There are a few ways that you could handle using both the endstop and the probe.

One way would be to use the Z endstop as the Z max as mentioned bofore. To do that you'd have to change M574 Z2 S1 P"whatever it is". Then you would need a macro to actually do the homing move. You could call it homezmax.g and in it you'd need a G1 H1 Z move in the positive direction to move to the endstop.

You could also make your homez.g macro (called by G28 Z) do that and use the homeall.g macro (called by G28) to use the probe instead.

Or leave the endstop as it is at z min, and have G28/homeall.g use just the endstops and then dedicated homez.g to using the probe.

The BLTouch will need to be mounted to actually be used and tested. Having it on the bench is going to lead to a crash.

-

@phaedrux I now have the BL Touch on the printer. I am testing by Homing the X&Y independently. I then move to the middle of the bed and send a G30 command to isolate the issue. The Z will lower until the probe touches. It will the inconsistently retract and my probe display console will read 0, but most of the time the Z it will continue down and the probe attempts to extend hitting the bed before it fully extends. I will either E Stop or the Z probe will get a 1000 in the display console.

-

@signpostman said in BL Touch Installation what is Servo Pin?:

I'm having trouble understanding what you are describing.

Keep in mind that when a M401 command extends the probe tip, the retraction of the probe tip, when touched, is handled by the probe and the probe tip immediately extends again.

When executing a G30 command there follows a M401 command which extends the probe tip. When the probe tip is touched it retracts sending a signal to the firmware. If the signal is seen by the firmware there follows a M402 command which retracts the probe tip, it stays retracted and then movement stops. If the signal is NOT seen by the firmware the probe tip will extend again but the movement will not stop.

I would like you to do this:

- change the A parameter in the M558 command to A1

- move the bed well clear of the probe so you can easily reach in and touch the probe tip. Move the probe to the front of the bed if needed

- execute a G30 command

- determine if bed movement starts

- touch the probe tip

- determine if bed movement stops

- if it does not stop and the probe tip has extended touch it again

- determine if bed movement stops

I'm guessing here but I think the firmware is not consistently seeing the signal from the probe. The above is to try and determine is that is the case.

Repeat the test several times starting with step 2 where you move the bed well clear of the probe.

Frederick

-

Can you post your full config.g as it is now along with your current homing files so we can see what your settings are?

-

@fcwilt I set the A to 1, the Max Taps was 1.

The method your describing is what I have done, I must touch it multiple time (different number each time. I even change the S Parameter to 5 and tested it with the same result. I have since changed it back.

-

I have tested by inputting G30 in the command line with the same result

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.0 on Sat Aug 21 2021 12:25:45 GMT-0400 (Eastern Daylight Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name ; Drives M569 P40.0 S1 ; physical drive 40.0 goes forwards M569 P41.0 S1 ; physical drive 40.0 goes forwards M569 P42.0 S1 ; physical drive 42.0 goes forwards M569 P43.0 S1 ; physical drive 42.0 goes forwards ;M569 P125.0 S1 ; physical drive 125.0 goes forwards M584 X40.0:41.0 Y42.0 Z43.0 ;E125.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y200.00 Z200.00 E420.00 ; set steps per mm M566 X900.00 Y900.00 Z900.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z2000.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z250.00 E250.00 ; set accelerations (mm/s^2) M906 X2500 Y1200 Z1200 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X2300 Y1300 Z304 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!^40.io1.in" ; configure active-high endstop for low end on X via pin !^40.io1.in M574 Y1 S1 P"!^42.io1.in" ; configure active-high endstop for low end on Y via pin !^41.io1.in M574 Z1 S1 P"!^43.io1.in" ; configure active-high endstop for low end on Z via pin !^43.io1.in ; Z-Probe M950 S0 C"io5.out" ; create servo pin 0 for BLTouch M558 P9 C"io5.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as thermocouple via CS pin spi.cs1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S500 ; set temperature limit for heater 1 to 500C ; Fans M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.3.0 on Sat Aug 21 2021 12:06:10 GMT-0400 (Eastern Daylight Time) G91 ; relative positioning G1 H2 Z30 F6000 ; lift Z relative to current position G1 H1 X-2305 Y-1305 F3000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F6000 ; go back a few mm G1 H1 X-2305 Y-1305 F180 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X250 Y650 F3000 ;move probe to centre of bed G30 ; probe bed ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 Z20 F1800 ; lift Z relative to current position G90 ; absolute positioning; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.3.0 on Sat Aug 21 2021 12:06:11 GMT-0400 (Eastern Daylight Time) G91 ; relative positioning G1 H2 Z10 F6000 ; lift Z relative to current position G1 H1 Z-309 F2500 ; move Z down until the endstop is triggered G1 H2 Z5 F6000 ; go back a few mm G1 H1 Z-20Y F180 ; move slowly to Z axis endstops once more (second pass) ;G92 Z0 ; set Z position to axis minimum (you may want to adjust this) G30 ; probe bed ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 Z20 F2500 ; lift Z relative to current position G90 ; absolute positioning -

@signpostman said in BL Touch Installation what is Servo Pin?:

@fcwilt I set the A to 1, the Max Taps was 1.

The method your describing is what I have done, I must touch it multiple time (different number each time. I even change the S Parameter to 5 and tested it with the same result. I have since changed it back.

That would seem to confirm my belief that the signal from the probe to the board is inconsistent.

I have two printers with a BLTouch but the wire lengths are perhaps 1 meter.

One difference I have from your setup is the M558 command prefixes the pin name with the ^ character.

What sort of wire is used to extended the black/white pair back to the board?

Frederick

-

@fcwilt I have tried CAT 5 cable and now I have 18 gauge 4 conductor that is not twisted pair

-

Should it look like this?

-

@signpostman said in BL Touch Installation what is Servo Pin?:

@fcwilt I have tried CAT 5 cable and now I have 18 gauge 4 conductor that is not twisted pair

I would remove one twisted pair from the CAT cable and use that. And I would make sure to route it away from any source of noise, like stepper wiring.

Frederick