Dual Extruders at the same time

-

Hello. I am working with a Modix big 60, which uses a duet 2 ethernet board.

I want to configure the printer to be able to use both print heads at the same time in order to double the output. I have mounted two gantries to the same axis and adjusted the config file so that the printer only thinks it can print on half of the y bed size. I have also adjusted the code in order to have both heaters take the input of heater 1 and the thermistors to still read and monitor the temps of each extruder so I don't get any thermal runaway.My issue is that I need to adjust the g-code so that the secondary extruder motor takes the same inputs as the primary extruder motor.

Any Assistance would be very helpful!Thank you

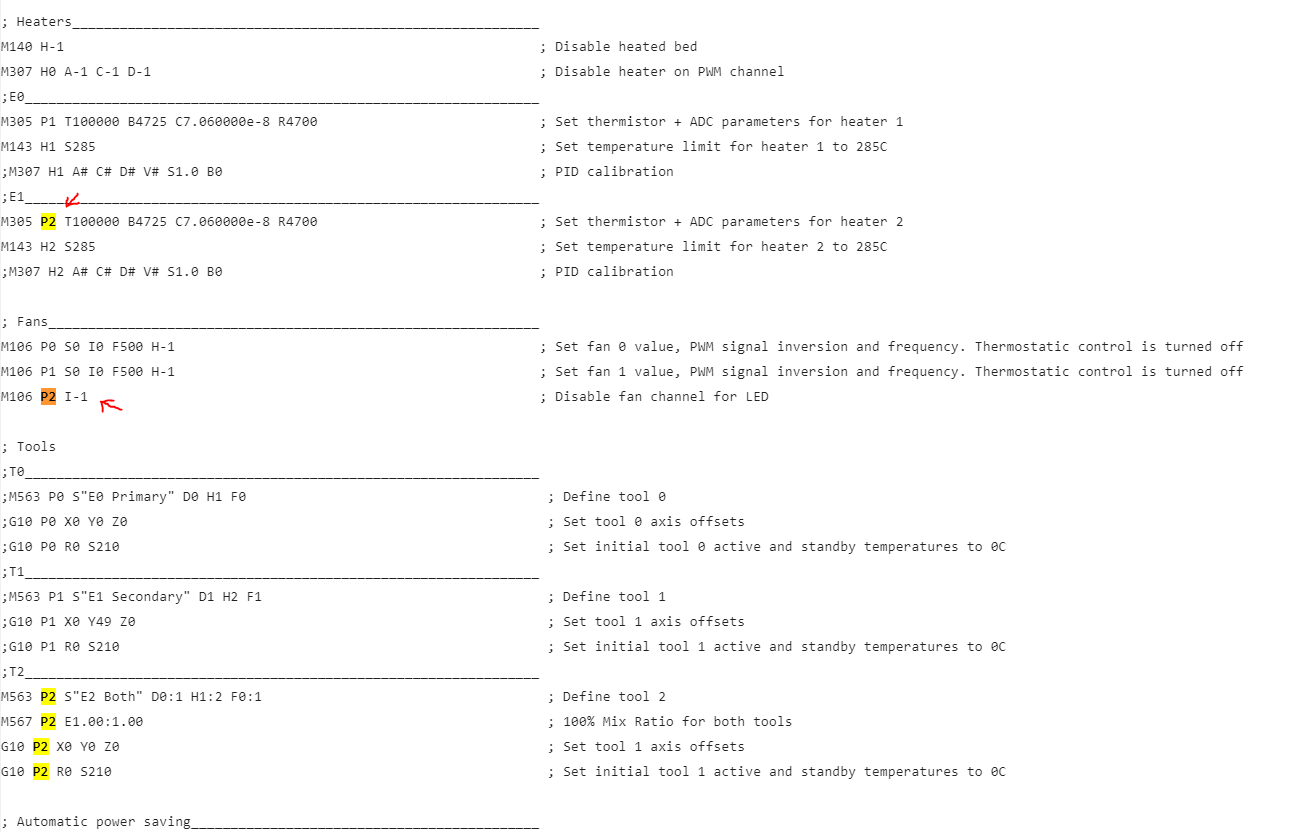

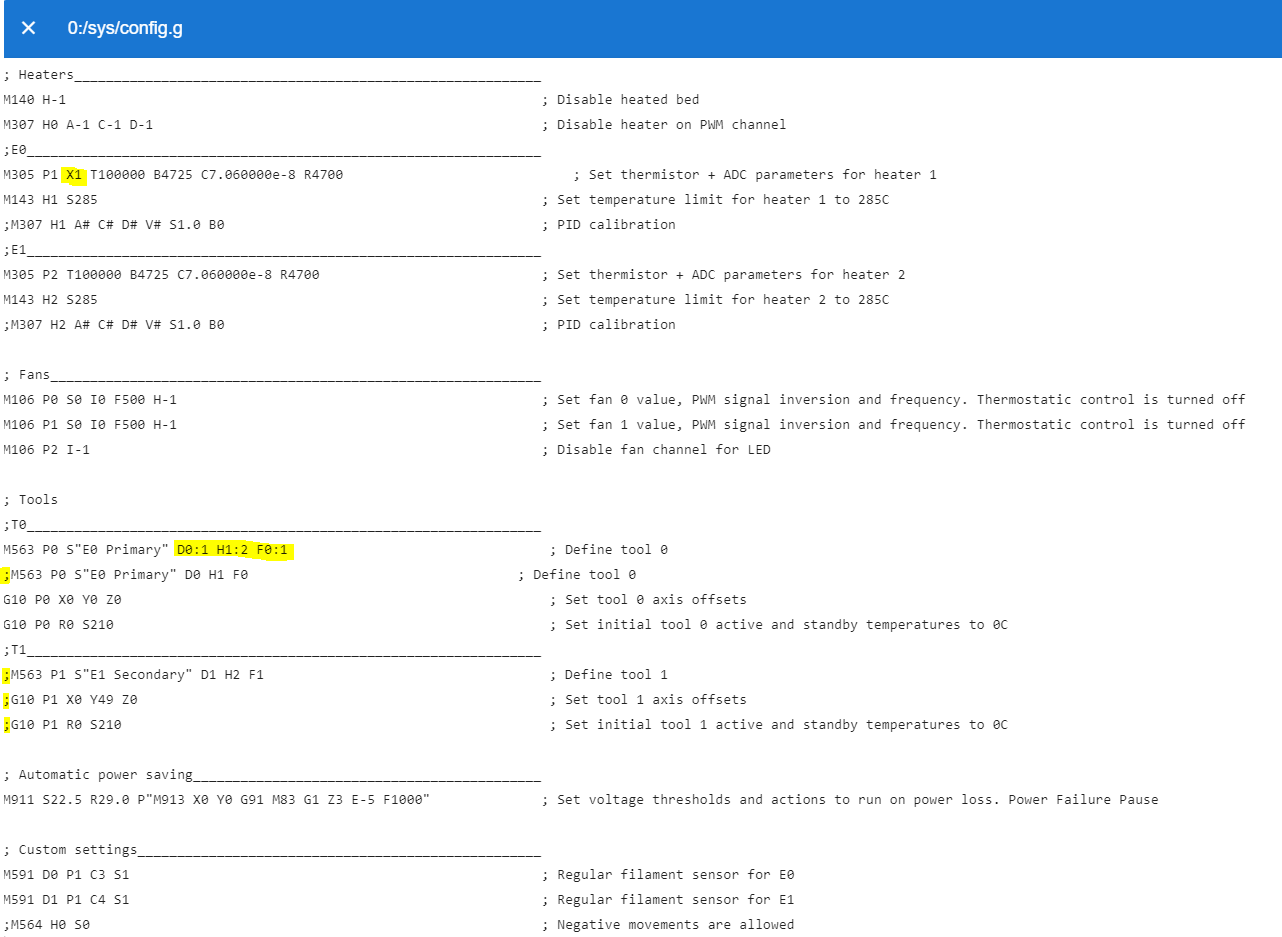

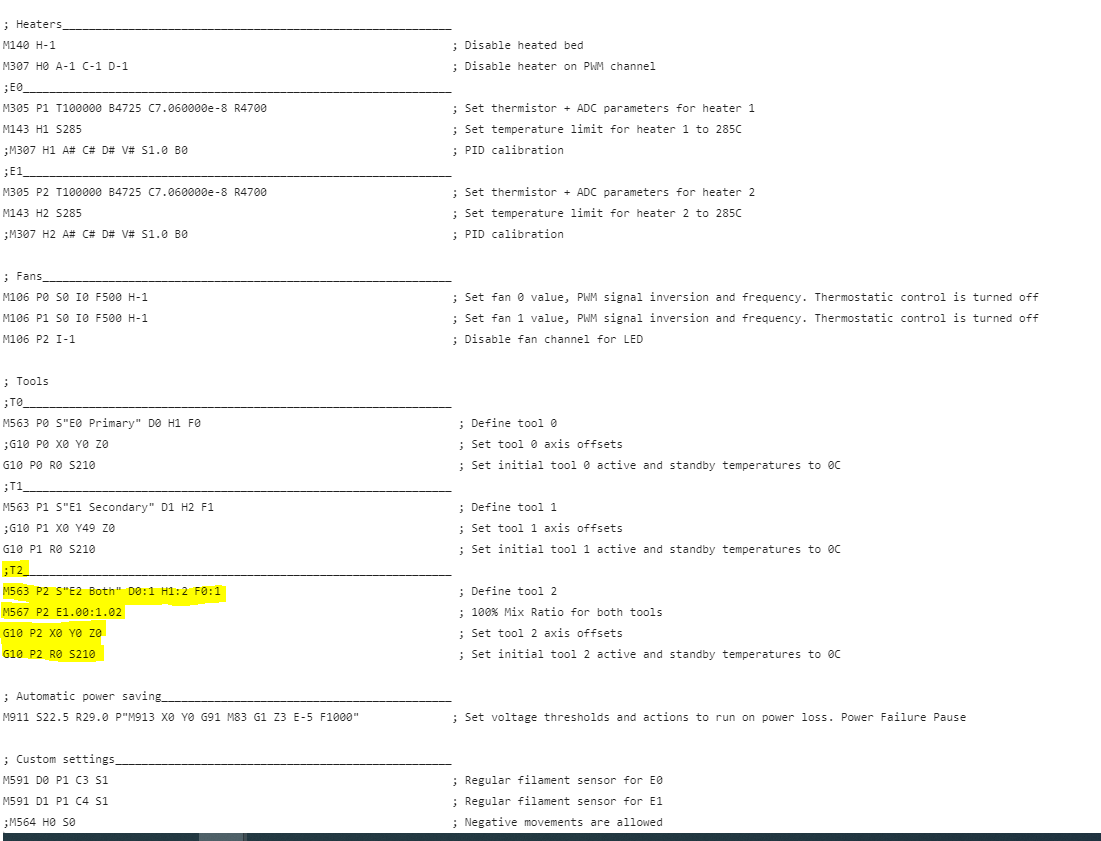

This is the Config.g file that I have been modifying. The changes made are highlighted.

-

@djthuma One way to do it is to define a tool to use both extruders. You are almost there with your highlighted changes but the bit you are missing is to set the mixing ratio to "tell" the firmware what percentage of each extruder to use. In this case it would be 100% of each.

I would put tools 0 and 1 back to what you had and define a third tool (T2). That way you can use either just Tool 0, or Tool 1 or both (Tool2)

So pretty much as you had - i.e.

M563 P2 S"Both" D0:1 H1:2 F0:1; define tool to use both extruders

then you need

M567 P2 E1.00:1.00 ; this will set the mixing ratio to 100% for each extruder. -

@deckingman

Thank you for the help!!Hows this?

Is that all?

Do I need to define which heater config to use? or will it go with T2 as long as the others are commented out?

Any Adjustment in Cura? -

-

@djthuma said in Dual Extruders at the same time:

I'm worried because P2 is being used in another line. Will this have any effect?

No. The "P" parameter is just a reference to whatever object the command is using. So in M563 P2 refers to Tool2, in M303 P2 refers to sensor number 2. In M106, P2 refers to fan number 2.

I know - it would make a lot more sense if Tools were always referenced by T", Fans by "F", Sensors by "S", Drives by "D" etc, but gcode seems to be governed by some sort of standard and historical conventions which defy logic.

-

@djthuma said in Dual Extruders at the same time:

Hows this?

Looks OK at a glance

Do I need to define which heater config to use? or will it go with T2 as long as the others are commented out?

Any Adjustment in Cura?It should work - try it and see. TBH, I'm not 100% sure how M104 / M109 behave when multiple heaters are assigned to a tool. I would hope that they would set the active temperature for both heaters. But a safer way would be to use G10 with a colon separator. e.g. G10 T2 R140:140 S205:205 would set the standby temperatures for both heaters to 140 and the active temperatures for both heaters to 205. Then use M116 P2 to wait for those temperatures to be reached.

-

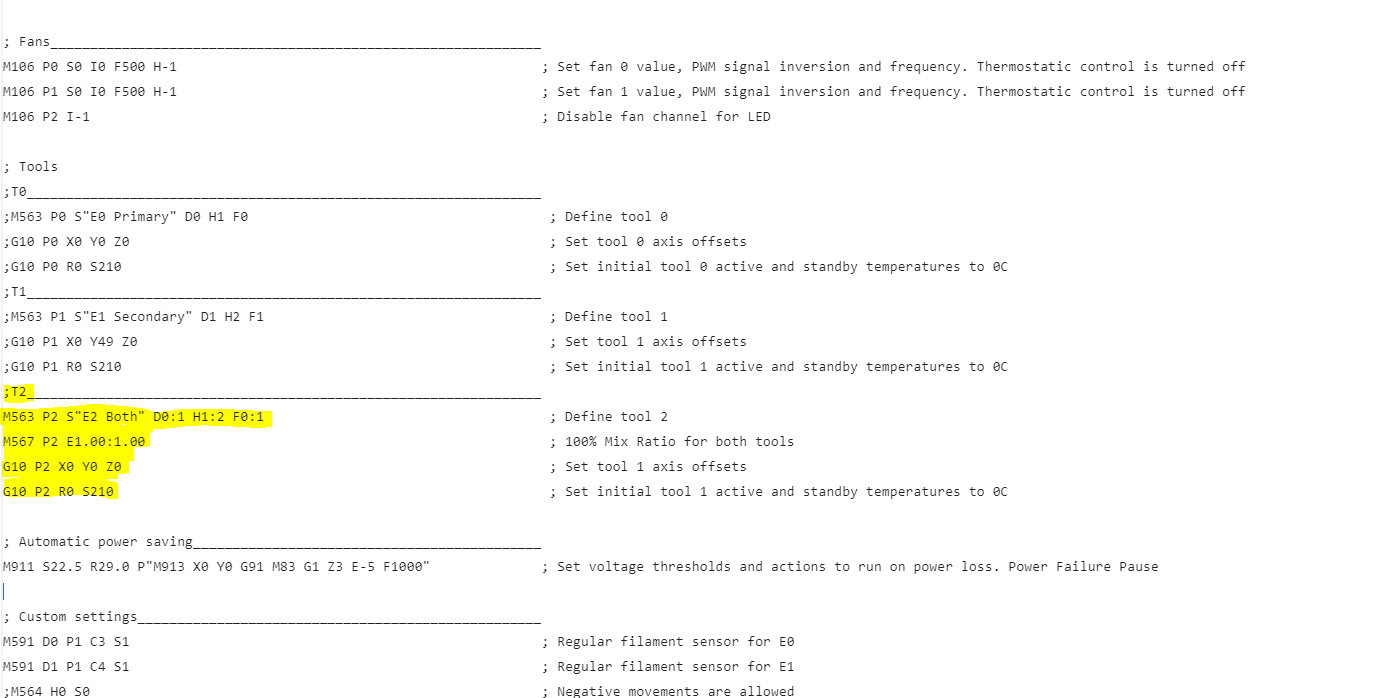

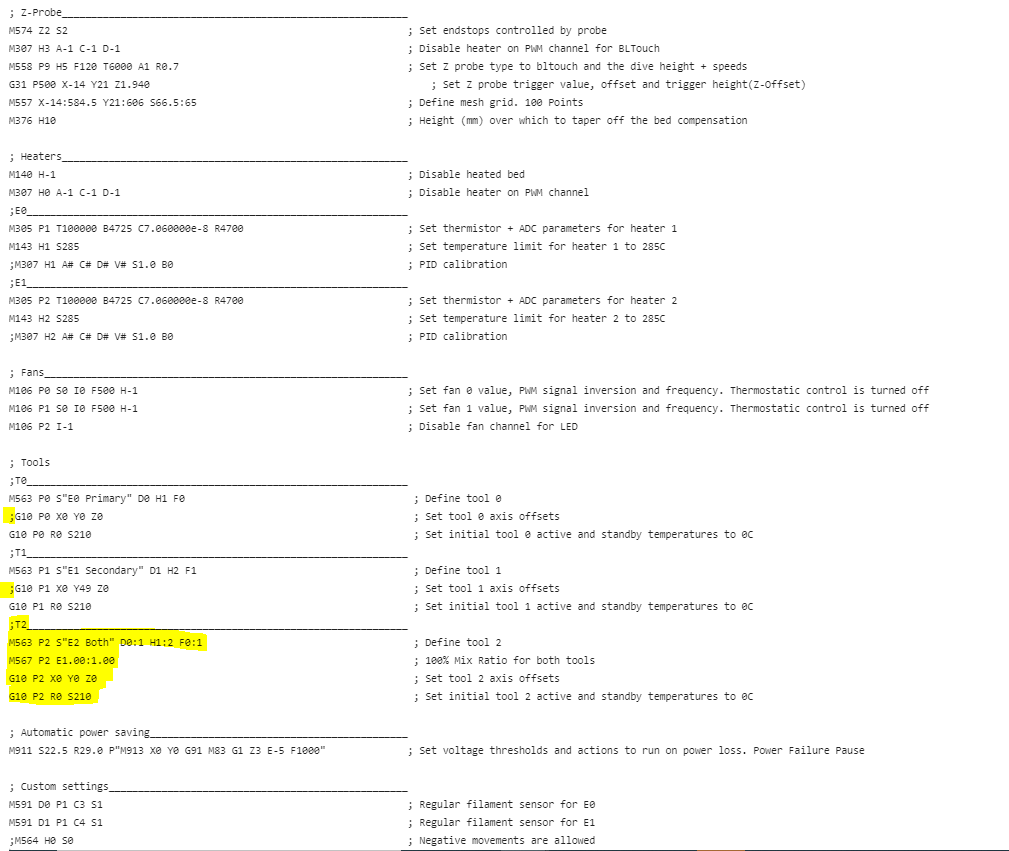

This is what i've got now.

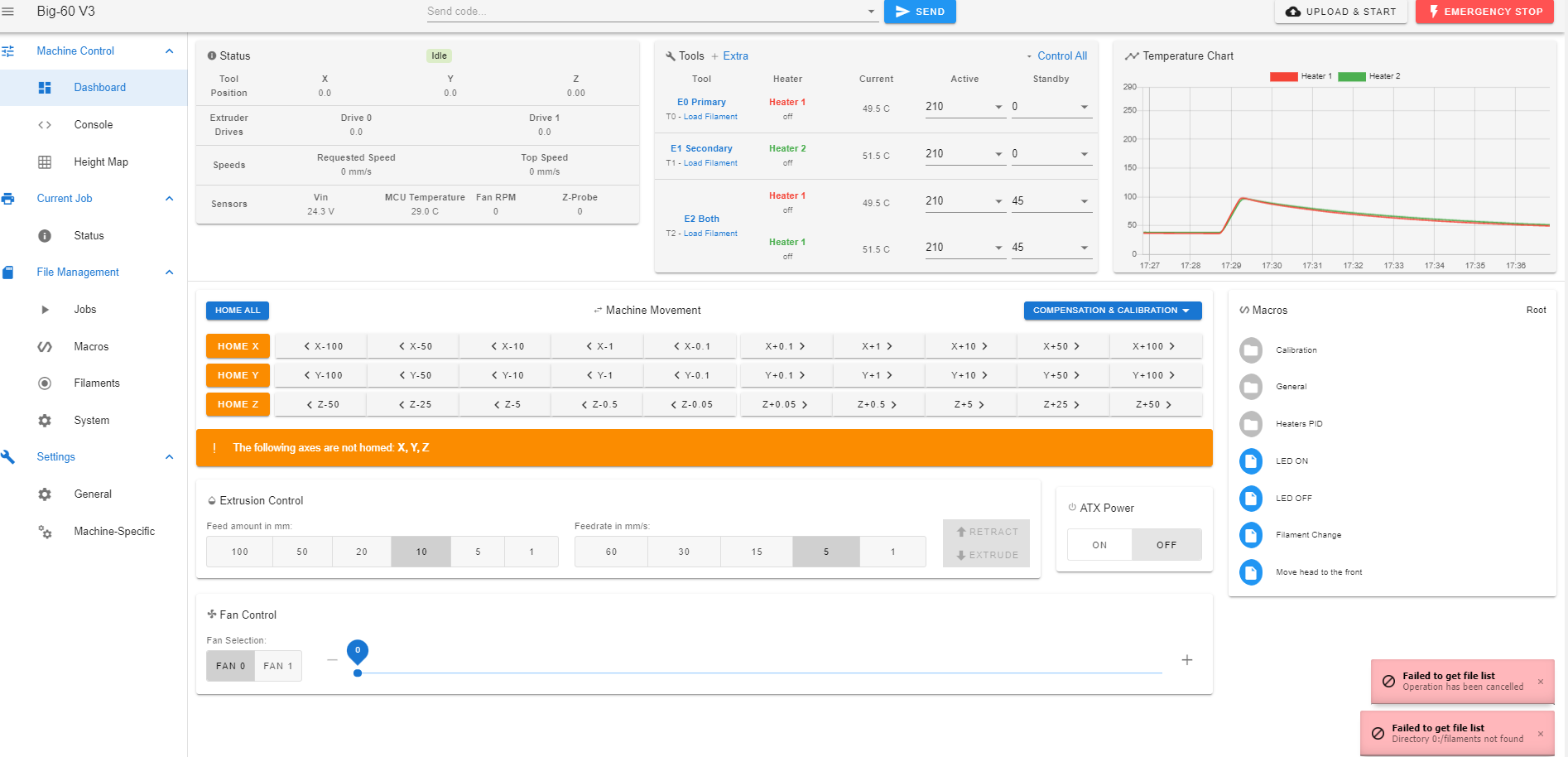

WebControl is showing this.

Should be working for a test. I can test tomorrow.

I have a simple hollow box test in cura which will drive the main gantry and hopefully copy to the secondary gantry. cura thinks it is only printing one object and the machine should drive both extruders. Do you think this configuration would do that? -

@djthuma said in Dual Extruders at the same time:

This is what i've got now.....................

...................... Should be working for a test. I can test tomorrow.

I have a simple hollow box test in cura which will drive the main gantry and hopefully copy to the secondary gantry. cura thinks it is only printing one object and the machine should drive both extruders. Do you think this configuration would do that?I would think that should work. Before you try a print, select Tool 2, heat it to print temperature, then extrude (say) 50 mm of filament. If you use the extrusion control of DWC, with tool 2 active, you should see options to use either extruder 0 or extruder 1 or "Mix". Using "Mix" should extrude filaments from both hot ends.

-

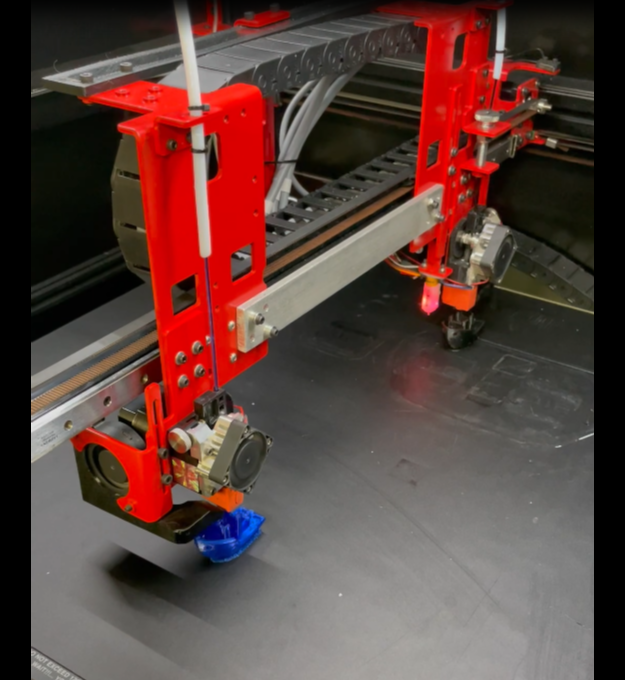

Got it working! The first test were some classic benchys. They actually came out at a great quality, even the slave gantry!

Here is the config file adjustment! I created a third tool that runs both of the extruders and heats them up to the same temperatures.

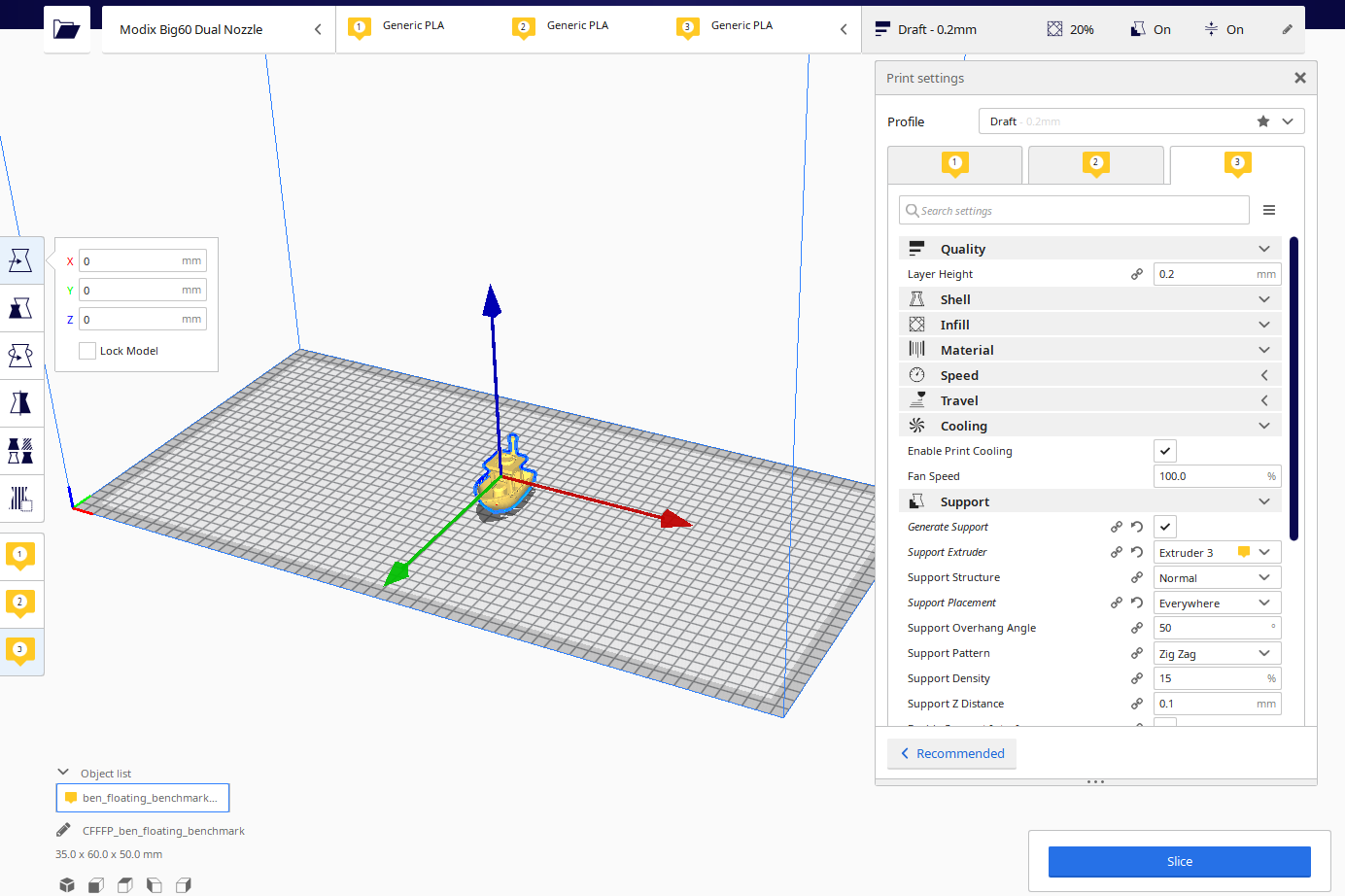

Lastly, I had to create a cura profile that would work. Basically, I created a third tool in cura and cut the y-axis in half for the offset of the second tool head.

The machine thinks it is only creating one object, but actually outputting two!

-

@djthuma Glad that worked out for you - I thought it would.