Heater and other problems after v2 to V3.3 upgrade

-

Hi all,

Looking for some support after an extremely frustrating day.

I have a home built Delta connected to a Duet2 Ethernet, PanelDuo, PT100 RTD board.

This morning after a largely unsuccessful print (other issues related to filament) I decided to finally update from the existing v2.something to v3.

read the install guide, updated the single .bin file for v3.0 and then started looking at the crazy list of config changes.Problems:

Heaters (1 x bed on 0, 2 x nozzle on 1 and 2) not working, sensors not seen - if I activate the bed heater, it generates an error "Error: Temperature reading fault on heater 0: sensor open circuit"

temperature on both operating heaters is -273.1C

Bed appears to heat on startup, although the sensor is apparently ignored.

Reading the config file for syntax errors produces a string of problems (below)Any aid gladly received.

Simon; Configuration file for Duet WiFi (firmware version 1.20 or newer)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Tue Apr 17 2018 23:13:51 GMT+0200 (Romance Daylight Time); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; manualo calibration 25-03-20

M665 R173.334 L334.238 B125 H303.804 X0.016 Y0 Z 0.000 ; Set delta radius, diagonal rod length, ;**Probe too high, reduce numberM666 X0.80 Y0.60 Z-0.5 A0.0 B0.0 ; Put your endstop adjustments here, or let auto calibration find them

; Network

M550 P"Kossel" ; Set machine name

M552 P192.168.1.58 S1; IP address (0 = use DHCP);*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S0 ; Drive 3 goes backwards - extruder 1

M569 P4 S0 ; Drive 4 goes backwards - extruder 2

M584 X0 Y1 Z2 E3 E4 ; set drive mappingM350 X16 Y16 Z16 E16:16 I1 ; Configure microstepping with interpolation

M92 X100 Y100 Z100 E450:830 ; Set steps per mm

M566 X1200 Y1200 Z1200 E1200:1200 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000 Y18000 Z18000 E12000:12000 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z1000 E1000:1000 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E1000:800 I30 ; Set motor currents (mA) and motor idle factor in per cent ***SD changed from 800-1000 for Nylon E0 feed

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

;M574 X2 Y2 Z2 S1 ; Set active high endstops Old code

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstop; Z-Probe

M558 P1 H2 F120 T6000 ; Set Z probe type to unmodulated and the dive height + speeds

G31 P499 X0 Y22 Z2.103 ; Set Z probe trigger value, offset and trigger height Z1.93

M557 R100 S20 ; Define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T4700 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limitM140 H0 ; map heated bed to heater 0

M143 H0 S100 ; set temperature limit for heater 0 to 100C;M305 P1 X200 S"Left" ; PT100 daughter board, channel PD1 = Head 1 *** remove this for LH head ***

;M305 P2 X201 S"Right" ; PT100 daughter board, channel PD2 = Head 2 old codeM308 S1 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 1

M143 H2 S280 ; Set temperature limit for heater 2 to 280C;M307 H1 A375.1, C178.5, D4.1 S1 ; original PID parameters for heater 1 not used

M307 H1 A403.4, C180.0, D5.5 S1 ; PID parameters for heater 1 *** remove this for LH head ***

M307 H2 A499.6, C216.2, D5.1 S1 ; PID parameters for heater 2, autotuned 1/9/19; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H-1

M950 F2 C"fan2" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P2 S1 H-1 ; set fan 0 value. Thermostatic control is turned off; Tools

;M563 P0 D0 H1 S" Single" ; Define tool 0 *** remove this for LH head ***

;G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets *** remove this for LH head ***

;G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C *** remove this for LH head ***

M563 P1 D1 H0 H2 S"Double" ; Define tool 1

G10 P1 X0 Y0 Z0 ; Set tool 1 axis offsets 18mm between nozzles, symmetric about zero (either here or in Cura, not both!!)

G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C; Automatic saving after power loss is not enabled

; Custom settings are not configured

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

Error: GCodes: Attempt to read a GCode unsigned array that is too long: M350 X16 Y16 Z16 E16:16 I1

Error: GCodes: Attempt to read a GCode float array that is too long: M92 X100 Y100 Z100 E450:830

Error: GCodes: Attempt to read a GCode float array that is too long: M566 X1200 Y1200 Z1200 E1200:1200

Error: GCodes: Attempt to read a GCode float array that is too long: M203 X18000 Y18000 Z18000 E12000:12000

Error: GCodes: Attempt to read a GCode float array that is too long: M201 X1000 Y1000 Z1000 E1000:1000

Error: GCodes: Attempt to read a GCode float array that is too long: M906 X1000 Y1000 Z1000 E1000:800 I30

Error: M558: Missing Z probe pin name(s)

Error: G31: Invalid Z probe index

Warning: M307: heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 365C.Warning: M950: Sensor number 2 has not been defined

Error: M307: Heater 1 not found

Warning: M307: heater 2 appears to be over-powered. If left on at full power, its temperature is predicted to reach 524C.Error: M563: Tool creation: bad drive number

Error: G10: Attempt to set/report offsets and temperatures for non-existent tool: 1

Error: G10: Attempt to set/report offsets and temperatures for non-existent tool: 1 -

I think you need to regenerate your config.g (and others) using the RRF configuration since RRF3.x uses different GCODE for its configuration.

https://configtool.reprapfirmware.org/Start

For those GCODE errors, go to the GCODE Wiki and look at each one.

I looked at the M201 error and you can no longer do E1000:1000 I suspect all the others are similar.But generating a new config using the RRF configurator is the right way to go.

SAVE YOUR OLD CONFIGS FIRST as a backup and to compare with when typing in things to the RRF configurator.

-

@simon0362 the "float array is too long" errors are reported because you need to declare the extruder driver numbers using M584.

-

@dc42 thanks David, I have just found that the correct syntax for M584 is "E3:4" and not as I had: "E3 E4".

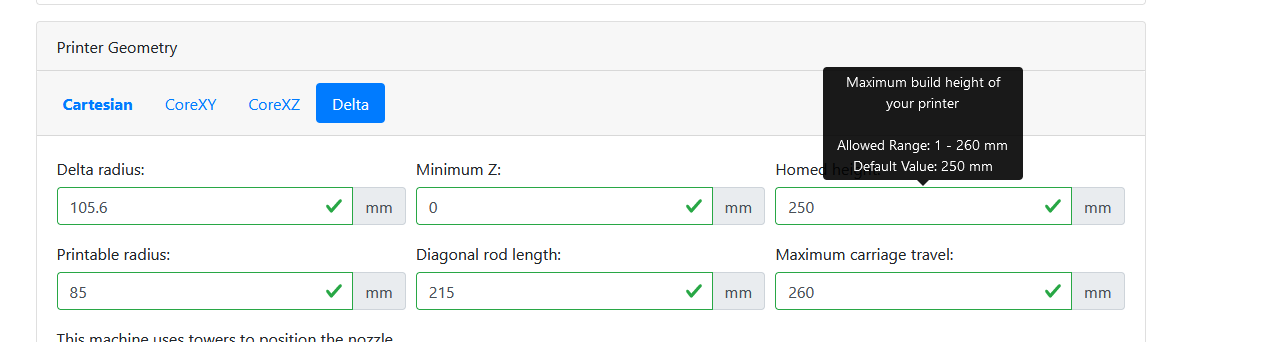

@alankilian, I regenerated a new config and then merged the two versions to attempt to maintain context - and I found the configurator to be unclear for some things and not let others happen (my bed height is 303mm, max allowed in theconfigurator is 250mm for instance)

still unclear why neither temperature sensor is reading and the bed is shown as 'unconnected"

-

@simon0362 said in Heater and other problems after v2 to V3.3 upgrade:

(my bed height is 303mm, max allowed in theconfigurator is 250mm for instance)

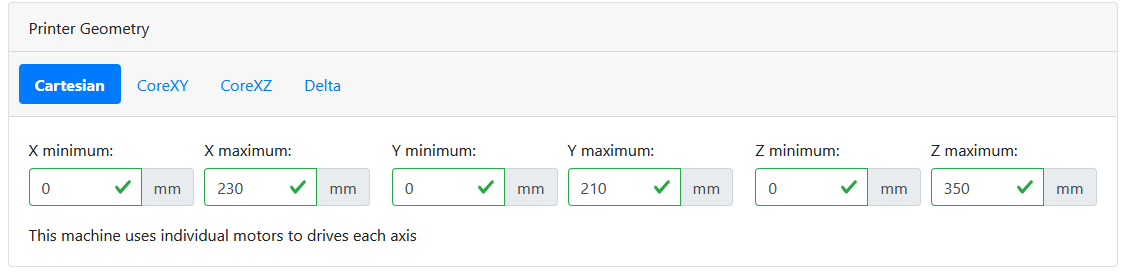

I was able to enter 350mm for Z in the configurator.

Where are you getting stuck?

-

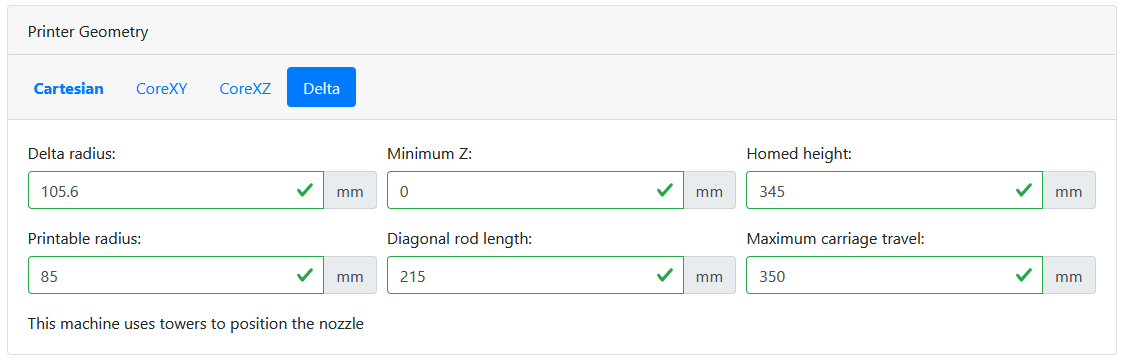

@alankilian set the configurator to Delta and as below:

-

Set "Maximum carriage travel" before setting "Homed height"

I got caught by that one also with my Delta.