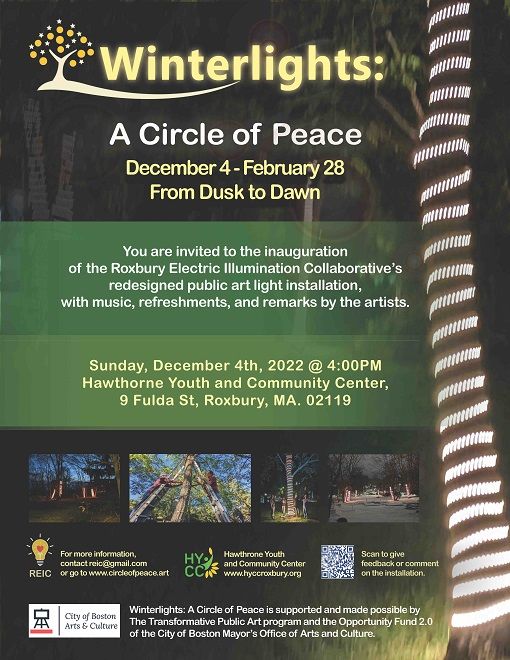

I've been helping some artists improve their LED control for "Breathing trees" here in Massachusetts by replacing a string of individually-controlled RGBW LEDs with a simple string of 12 Volt LEDs and a variable-voltage, Arduino-controlled power supply.

It's working wonderfully and I built them nine controller boards that plug into Arduinos and they are able to change the Arduino code, upload and design breathing patterns by themselves which is an awesome thing for the artists to be able to do.

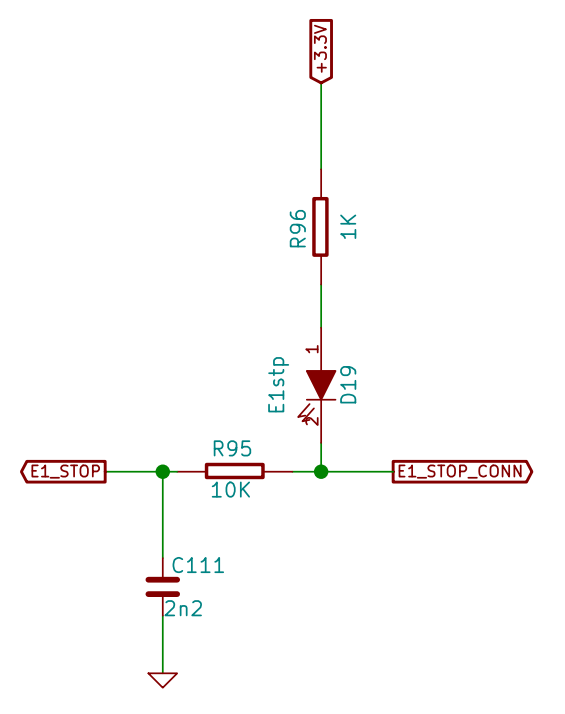

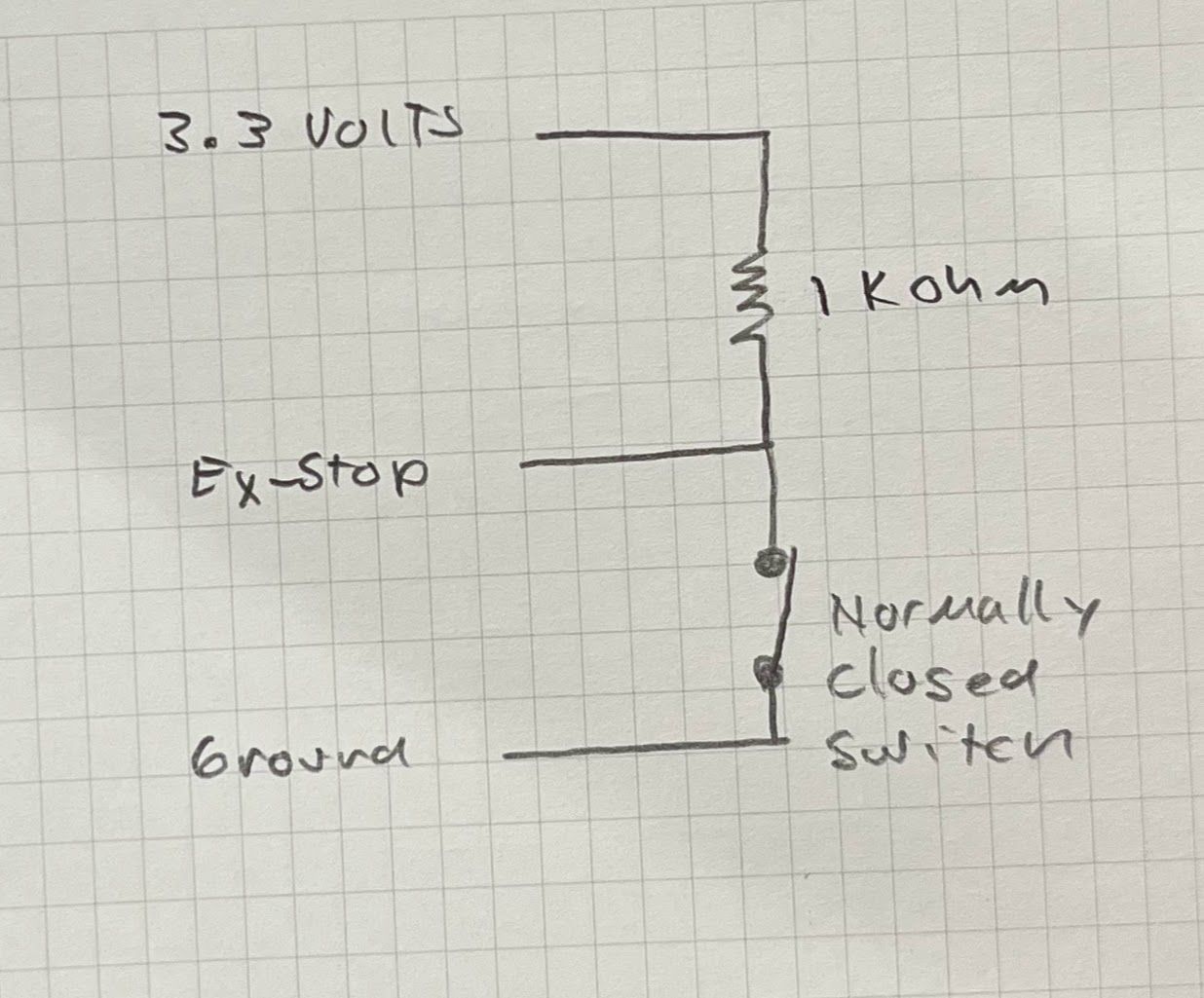

They are documenting everything and hoping to teach other artists how to control very dim LEDs without flickering for outdoor/dark use, so I'm sketching a schematic and documenting things.

I dug around to credit the people who did the original work I copied and guess what????

The original circuit I used as inspiration was from the good old @dc42 !!!

So, thanks Dave, your ideas spread far and wide and hopefully will be all the rage in artist/maker spaces in the future.

I'll add a link in the schematic to your posting so people can reference the original design.