Duet3 6HC + load cell + amp

-

Hi,

I'd like to use a load cell + amp (e.g. the HX711/INA333/ADS1242, any amp will do, it's gonna have low requirements) to have an ongoing measurement of my filament spools' weight so I can see how much I have left.

I've seen people reference using a load cell for a Z-probe, so I assume it's possible?

My question is how do I connect it up?

I can't find anyone who's done it provide actual directions...

I'd really like to set it up as a sensor (i.e. using the M308 command) so it can be graphed on the DWS temp graph (like you can with filament humidity for example)Many thanks for any help with this.

-

Something like this should do for spool weight measuring; 2KG full scale so about right for a 1Kg spool and supports:

https://www.amazon.co.uk/Weight-Sensor-Weighing-Arduino-Raspberry-Black/dp/B07G2QVVH3Interfacing or display is another matter; I did not know about such as the humidity graph?

-

https://forum.duet3d.com/post/241194

https://forum.duet3d.com/post/253602Both have the mechanics of how to do it with a printer that has a Pi in the system. They don't graph, only display a current value.

I don't think graph will be terribly useful - it will sawtooth its way down all the time a print is running.

-

@rjenkinsgb Aye, the hardware is not the issue, it's just interfacing with the duet I need help with

You can connect a humidity (and temp) sensor for your filament and display values in graph per here: https://duet3d.dozuki.com/Wiki/Connecting_Digital_Humidity_and_Temperature_(DHT)_sensors

-

@achrn thanks, they're excellent

however they both use the pi as the processor

I was wondering if it's possible to connect directly to the duet

I may need to end up using the pi, but I'd prefer to use the duet if possible. I should've been more explicit in my question, apologies!

-

It looks like the M308 "linear-analog" option may do the trick?

That has scaling values in the setup to calibrate the displayed range, which presumably would be the empty spool and full spool output levels from the load cell amp to suit 0 and 1000 grams, or 0-100% depending how it works.

On the 6HC, it appears the inputs on IO3 to IO7 inclusive are analog capable, so should be usable in this manner?

https://duet3d.dozuki.com/Wiki/M308

https://duet3d.dozuki.com/Wiki/Duet_3_Mainboard_6HC_Hardware_Overview#Section_IO

-

@jhalewood I haven't seen anyone publish about using an analogue amp on a bridge load cell to feed an ananlogue signal direct to the Duet.

You could be first! Blaze a trail!I agree the INA333 looks plausible for that (from a quick glance at the data sheet).

-

@jhalewood we've done something similar before. In outline:

- Use an op amp in the voltage follower configuration, fed from the thermistor reference voltage Vref, to power the load cell bridge.

- Use a INA333 to amplify the output from the load cell.

- Use an op amp in the non-inverting configuration to buffer the output from the INA333 and to provide additional amplification

- Feed the output of that op amp into a Duet thermistor input

- Configure it as a linear analog sensor in M308.

If using Duet 3 then you can gain a little extra accuracy by connecting the reference terminal of the INA333 to Vssa instead of to ground.

-

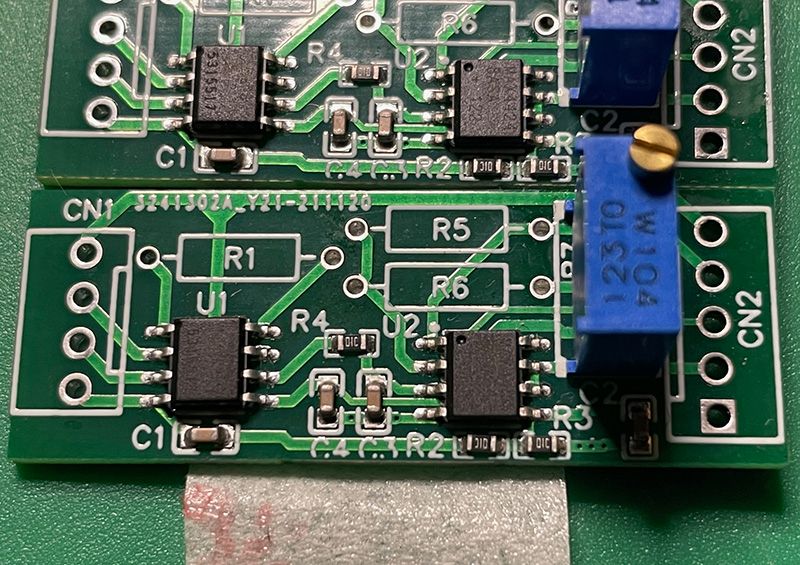

@jhalewood

If you are in the UK, one of these may be suitable, to save some construction?

I did a small batch to test a concept in a robotics project, but I don't need them all.

They have an AD623 instrumentation amp for the load cell input followed by a MAX44248 precision opamp in non-inverting configuration for extra gain & gain trimming.

The positions for conventional resistors set the AD623 gain and the gain range of the second stage.

The reference for both stages is from one of the connections.

-

@rjenkinsgb Thanks mate, very kind, but I'm not in UK

One of your colonies... -

undefined droftarts referenced this topic

undefined droftarts referenced this topic