PID Issues 3.4 RC1

-

-

Sorry I have not uploaded a photo yet - been a bit busy- only got the printer fully assembled again this evening - weird thing now is the temperature stays about 10 to 15 degrees HOTTER than requested.

Did a tuning with 200C and PWM of 0.8 and this was the result:

M307 H1 R2.723 K0.545:0.322 D10.96 E1.35 S0.80 B0 V24.1

Rgds

Tinus -

That dead time of 10 seconds seems unusually high for an E3D V6 style hotend.

-

@phaedrux That's the 'D' parameter in the line? To what do you suggest should I decrease it?

-

It means it's taking 10 seconds for the sensor to register a change in temp between the time heat was requested and when it's detected. For my V6 it's closer to 2 seconds. So I wonder if there is something off with assembly causing that.

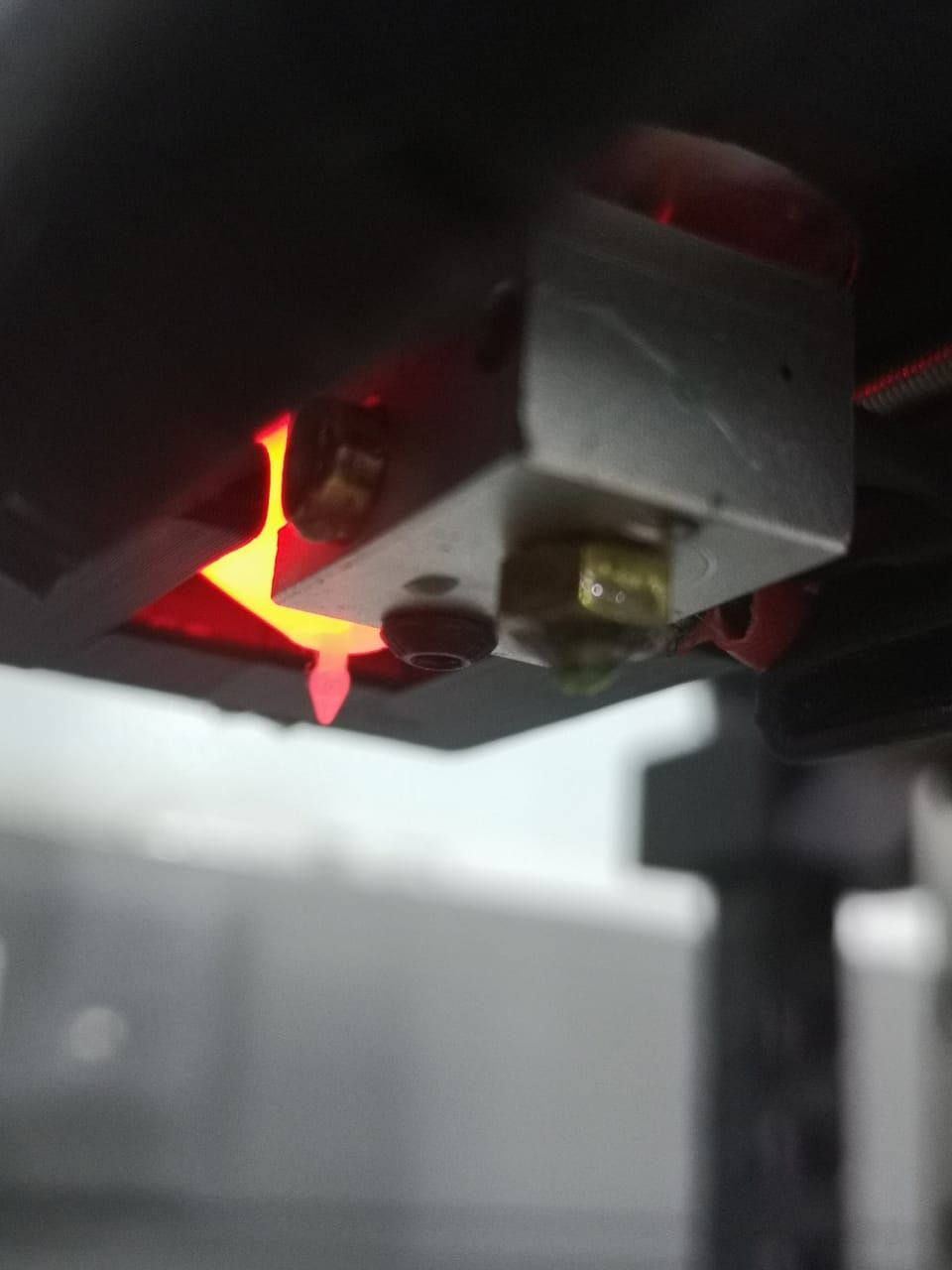

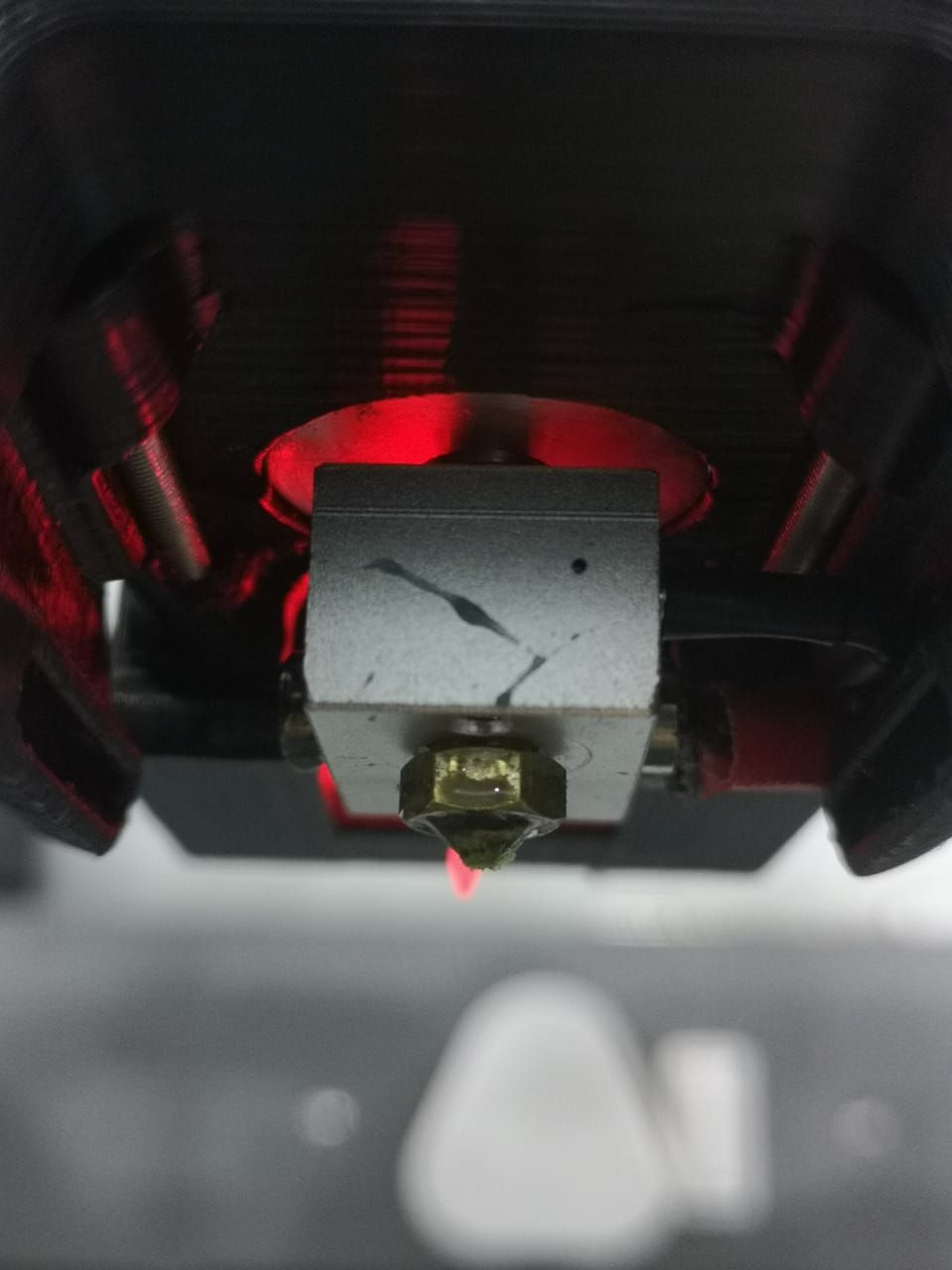

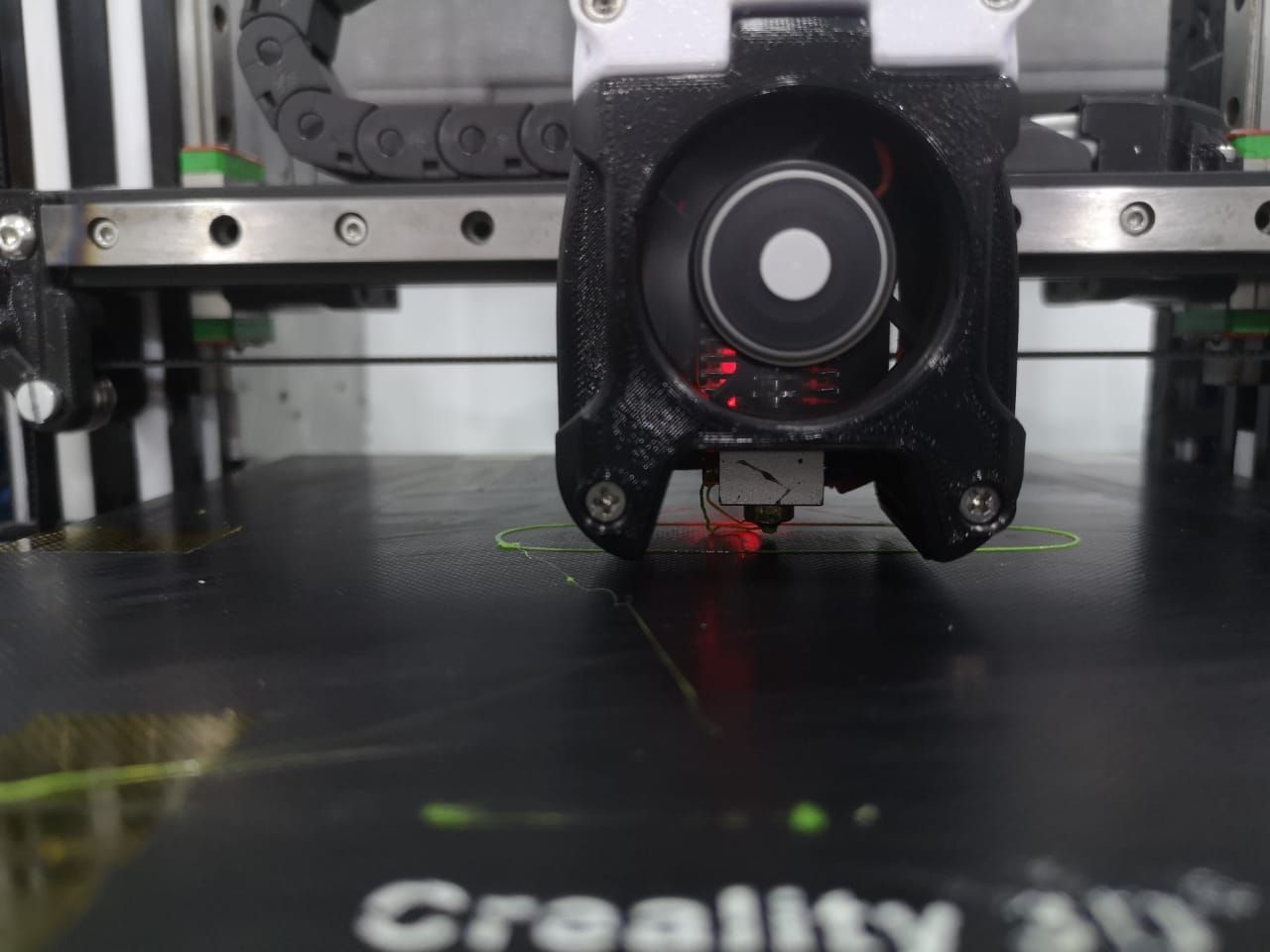

Hence the request for photos to see what is happening or if it's an unusual design etc.

Is the hot block in direct contact with the cold end heatsink or something? Or the heater cartridge or sensor not firmly secured?

-

@phaedrux Everything is firmly secured - did double check it

The only thing that may be a little weird is the gap between the nozzle and the heat block, may be a tad big.... but that should not be an issue, should it?

-

Maybe? We're looking for anything non-standard, so...

-

@phaedrux

Have you done a PID autotune with2.4rc13.4rc1?

I'm getting D values in the 10 second range with my E3D V6 as well.

As you probably know I've been experiencing issues with wild temperature fluctuations with later releases. -

@owend you mean 3.4rc1?

-

@reefwarrior Yes. My fingers are dyslexic

-

Not wanting to hijack this thread......

A search reveals that in November 2021 in V3.4.0b6 , I was getting PID results ofM307 H1 B0 R1.594 C358.1:217.5 D6.05 S1.00 V24.3With same hardware in 3.4rc1

M307 H1 R2.848 K0.325:0.197 D10.51 E1.35 S1.00 B0 V24.3Different algorithm of course, but I wouldn't have thought the dead time would change that much as a result and it may explain the over shoots I now get.

-

@owend I will try a different firmware version tomorrow, however 3.4 is needed to keep my mini12864 up and running. My overshoot is typically 10 to 15 degrees at the moment...

-

@reefwarrior said in PID Issues 3.4 RC1:

@owend I will try a different firmware version tomorrow, however 3.4 is needed to keep my mini12864 up and running. My overshoot is typically 10 to 15 degrees at the moment...

Overshoot is typically caused by the R parameter being too high. It appears to have increased significantly from earlier. Try reducing it.

-

-

Also:

M307 H1 R2.0 K0.545:0.322 D10.96 E1.35 S0.80 B0 V24.1 ;V3.4RC1

M307 H1 B0 R2.788 C90.8:60.3 D10.93 S0.80 V24.1 ;V3.3 -

My layer 1 printed perfectly. Just after beginning on layer two, temperature exceeded by 15 degrees; and cause a heater fault.

-

@reefwarrior Does the part cooling fan turn on for layer two? It seems as if the firmware is anticipating a drop in temperature from the cooling and and tries to compensate.

Do you have a nozzle sock to test with?

Also it seems like your heatsink fan may be acting to cool the hot block as well.

-

@phaedrux Hi. Yeah tested with a sock too. Same result. Hot end fan is isolated from heat block - there is like a round 'O' of plastic (like a divider) between the heat block and the fins.

Also what is the approximate time of a PID cycle with defaults? I quite frequently have 30+ minutes. I even swapped out the board this morning. Same result!

-

Also changed hot end fans. No difference.

-

@reefwarrior with cooling like that and no silicone sock over the heater block, you are certain to get a big temperature drop when the part cooling fan turns on. So I suggest you add a silicone sock, then re-run heater tuning for that tool. By running it for the tool (i.e. using the T parameter in the M303 command instead of the H parameter), it will tune with the fan both on and off, and help correct for the cooling effect of the fan.

Heater tuning on hot ends normally finishes fairly quickly. Heater tuning on bed heaters can take a long time, especially if the bed has high thermal mass so it cools down very slowly.

If the problem persists, please post a screen shot of the hot end temperature plot in DWC, from just before the first layer ends up until the heater fault.

As a last resort you can increase the allowed temperature variation using the M570 command; however if you get a temperature drop exceeding 15C when the fan turns on, that is likely to cause you extrusion problems.