Temperatures totally wrong 3.4 RC

-

@hernicz said in Temperatures totally wrong 3.4 RC:

@thedragonlord PID Tune your heater (H) instead of your tool (T). If you PID tune your heater it will not tune with the fan, therefore it will not (over)compensate it.

You can also remove the values for fan compensation in your present PID values.

I'll give it a try, thanks

-

@hernicz said in Temperatures totally wrong 3.4 RC:

@thedragonlord PID Tune your heater (H) instead of your tool (T). If you PID tune your heater it will not tune with the fan, therefore it will not (over)compensate it.

You can also remove the values for fan compensation in your present PID values.

It works thanks!

-

@thedragonlord You're welcome.

-

@thedragonlord Can you post the details of the heater settings that did not work along with the ones you have now that do work, DC42 may find them of interest. Do your new settings give a constant temperature during a print? Can you also confirm what version of RRF you are now running.

-

@thedragonlord as @gloomyandy said if the tuning is overcompensating for the fan, it would be good to understand why.

When tuning, does the cooling fan run at 100%?

Does the part cooling fan run at 100% when printing?

When each tool is parked parked, could the hot end fan be having an effect on nozzle cooling?

When each tool is parked, does the cooling fan continue to run?

When you reverted to RRF 3.3 and temperatures were stable, what M307 commands were used?

As requested before, please post your tool change macros so we can see what is going on. A sample Gcode file, or snippet of the commands sent at tool change, would also help.Ian

-

@droftarts said in Temperatures totally wrong 3.4 RC:

@thedragonlord as @gloomyandy said if the tuning is overcompensating for the fan, it would be good to understand why.

When tuning, does the cooling fan run at 100%?

Does the part cooling fan run at 100% when printing?

When each tool is parked parked, could the hot end fan be having an effect on nozzle cooling?

When each tool is parked, does the cooling fan continue to run?

When you reverted to RRF 3.3 and temperatures were stable, what M307 commands were used?

As requested before, please post your tool change macros so we can see what is going on. A sample Gcode file, or snippet of the commands sent at tool change, would also help.Ian

As I told before it's not related to a tool change because it doesn't work even with a single heater on. The fan isa always 100% in the tuning and during the print

-

@gloomyandy I wrote a post more than a month ago (maybe 2) about this. PID tuning is even worse when I did it with copper heatblock.

There might be some fix values in the PID tuning process or the heating control that totally sends temp off the chart.

I mean even if it's over target temp it still tries to compensate the part cooling fan by raising temperature, triggering heater fault after a while.

If you have a copper heatblock, at initial heatup it way overshots temp. The purpose of PID is to precisely reach target temp and sustain it in a changing environment. But when you use copper, heatup just doesn't slow down. It's like PID is hardcoded to aluminium heatblock.

I even tried manually adjusting the values with no luck, but even like this PID was far better than bang-bang.

-

@thedragonlord okay. Can you at least post the M307 you were using in 3.3? Then we might be able to reproduce the issue.

For now I’ll update the M303 instructions to say that if the feedforward isn’t working for the user, to tune heaters rather than tools, as @Hernicz suggests.

Without sufficient data and information to be able to understand the cause of issues and to reproduce them, it’s very difficult to resolve them.

Ian

-

@hernicz said in Temperatures totally wrong 3.4 RC:

If you have a copper heatblock, at initial heatup it way overshots temp. The purpose of PID is to precisely reach target temp and sustain it in a changing environment. But when you use copper, heatup just doesn't slow down. It's like PID is hardcoded to aluminium heatblock.

This is not true in my experience. I had E3D v6 copper block (with copper nozzle and titanium heatbreak) in my delta from new and had no problems with a number of v3.4 betas and RC1 & 2 on a MB6HC. All tuned fine (as tools, not heaters) and worked fine when tuned. So it's not the case that something fundamental in the tuning cannot accomodate a copper block.

I'm now using a Revo, so the concept of block dissapears somewhat, since there's heater - nozzle assembly without discrete block. FWIW, that has tuned fine too.

-

@hernicz this post? https://forum.duet3d.com/topic/26830/issues-with-pid-tuning-rrf-3-4-0-b7/

I’ll try and get @dc42 to look at all threads where PID tuning is an issue. If you spot more, please post them here. Maybe if they’re taken all together there may be a common issue that he can look at.

Ian

-

@droftarts said in Temperatures totally wrong 3.4 RC:

@thedragonlord okay. Can you at least post the M307 you were using in 3.3? Then we might be able to reproduce the issue.

For now I’ll update the M303 instructions to say that if the feedforward isn’t working for the user, to tune heaters rather than tools, as @Hernicz suggests.

Without sufficient data and information to be able to understand the cause of issues and to reproduce them, it’s very difficult to resolve them.

Ian

I've been not using 3.3 but 3.4 beta 6 but unfortunately I have no backup for the files...

-

@thedragonlord in the 3rd post in this thread, when running RC1, your M307 was

M307 H1 R2.033 K0.194:0.179 D6.99 E1.35 S1.00 B0 V23.9 M307 H2 R1.889 K0.191:0.164 D8.45 E1.35 S1.00 B0 V23.9That’s the format for 3.4beta7 and later. Are you are using these in 3.4beta6? If you’ve retuned and it’s working, please post what you’re currently using in beta6. Then we can at least compare the computed PID values for each method, to see where it differs.

If you’re now on RC2 and you retuned just the heater not tool (as it would seem from your other posts), and it’s working, post that, so again we can compare the PID with the non working tune.

Ian

-

@droftarts Yes, that's it.

-

@achrn I also have 50W heater running at 30V, but Voltage was taken to account.

I'm not the only one with this issue. Are you running on SBC or standalone?

-

@hernicz SBC

I'm not claiming you're not having problems, I'm saying the assertions that "If you have a copper heatblock, at initial heatup it way overshots temp" and "when you use copper, heatup just doesn't slow down" are not universally true.

I don't understand why voltage is relevant, if you tune at (near) the voltage you run at (and if you don't, then I think you should).

-

@achrn I mean after tuning the copper heatblock, heating up from room temp overshot it until triggered a heater fault. Like it didn't know when to slow down heating to reach target temp. It seems like PID tuning doesn't tune for heat up from ambient, only to hold target (yet it cannot even do that if you calibrate tool with cooling fan)

It may not be universally true, but I don't think any PID tuned heater should behave like this. The whole point of PID tuning is to eliminate this (and have a steady target temp).

I had a copper volcano heatblock with a 50W heater and copper nozzle. I don't have issues with aluminium heatblock.

SBC as well. Voltage is just additional info, may not be relevant.

-

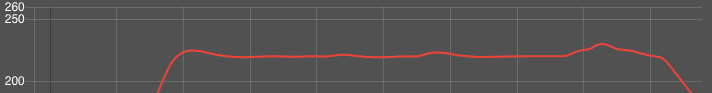

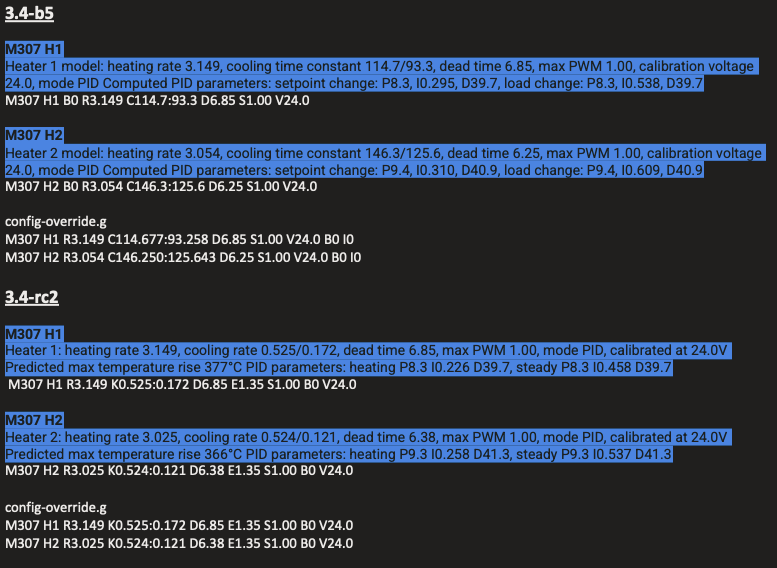

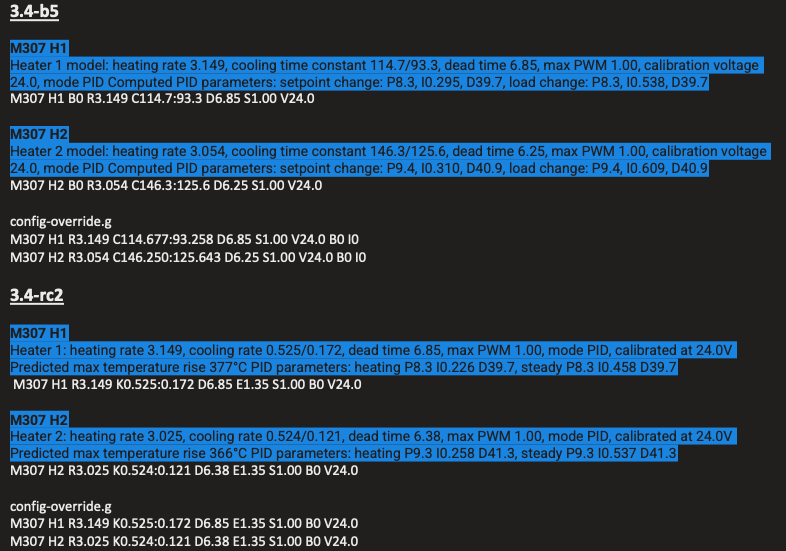

I wrote down my values.

What can I do to get rid of these fluctuations?

code_text ```3.4-b5 M307 H1 Heater 1 model: heating rate 3.149, cooling time constant 114.7/93.3, dead time 6.85, max PWM 1.00, calibration voltage 24.0, mode PID Computed PID parameters: setpoint change: P8.3, I0.295, D39.7, load change: P8.3, I0.538, D39.7 M307 H1 B0 R3.149 C114.7:93.3 D6.85 S1.00 V24.0 M307 H2 Heater 2 model: heating rate 3.054, cooling time constant 146.3/125.6, dead time 6.25, max PWM 1.00, calibration voltage 24.0, mode PID Computed PID parameters: setpoint change: P9.4, I0.310, D40.9, load change: P9.4, I0.609, D40.9 M307 H2 B0 R3.054 C146.3:125.6 D6.25 S1.00 V24.0 config-override.g M307 H1 R3.149 C114.677:93.258 D6.85 S1.00 V24.0 B0 I0 M307 H2 R3.054 C146.250:125.643 D6.25 S1.00 V24.0 B0 I0 3.4-rc2 M307 H1 Heater 1: heating rate 3.149, cooling rate 0.525/0.172, dead time 6.85, max PWM 1.00, mode PID, calibrated at 24.0V Predicted max temperature rise 377°C PID parameters: heating P8.3 I0.226 D39.7, steady P8.3 I0.458 D39.7 M307 H1 R3.149 K0.525:0.172 D6.85 E1.35 S1.00 B0 V24.0 M307 H2 Heater 2: heating rate 3.025, cooling rate 0.524/0.121, dead time 6.38, max PWM 1.00, mode PID, calibrated at 24.0V Predicted max temperature rise 366°C PID parameters: heating P9.3 I0.258 D41.3, steady P9.3 I0.537 D41.3 M307 H2 R3.025 K0.524:0.121 D6.38 E1.35 S1.00 B0 V24.0 config-override.g M307 H1 R3.149 K0.525:0.172 D6.85 E1.35 S1.00 B0 V24.0 M307 H2 R3.025 K0.524:0.121 D6.38 E1.35 S1.00 B0 V24.0 -

-

@Hernicz

M307 H1 R3.149 K0.525:0.172 D6.85 E1.35 S1.00 B0 V24.0you mean like that?

M307 H1 R3.149 D6.85 E1.35 S1.00 B0 V24.0

-

@jensus11 said in Temperatures totally wrong 3.4 RC:

@Hernicz

M307 H1 R3.149 K0.525:0.172 D6.85 E1.35 S1.00 B0 V24.0

you mean like that?

M307 H1 R3.149 D6.85 E1.35 S1.00 B0 V24.0No, leave in the first K parameter, so like:

M307 H1 R3.149 K0.525 D6.85 E1.35 S1.00 B0 V24.0Ian