duet wifi + duex5 RRF 3.3 I have engines that lose my pace

-

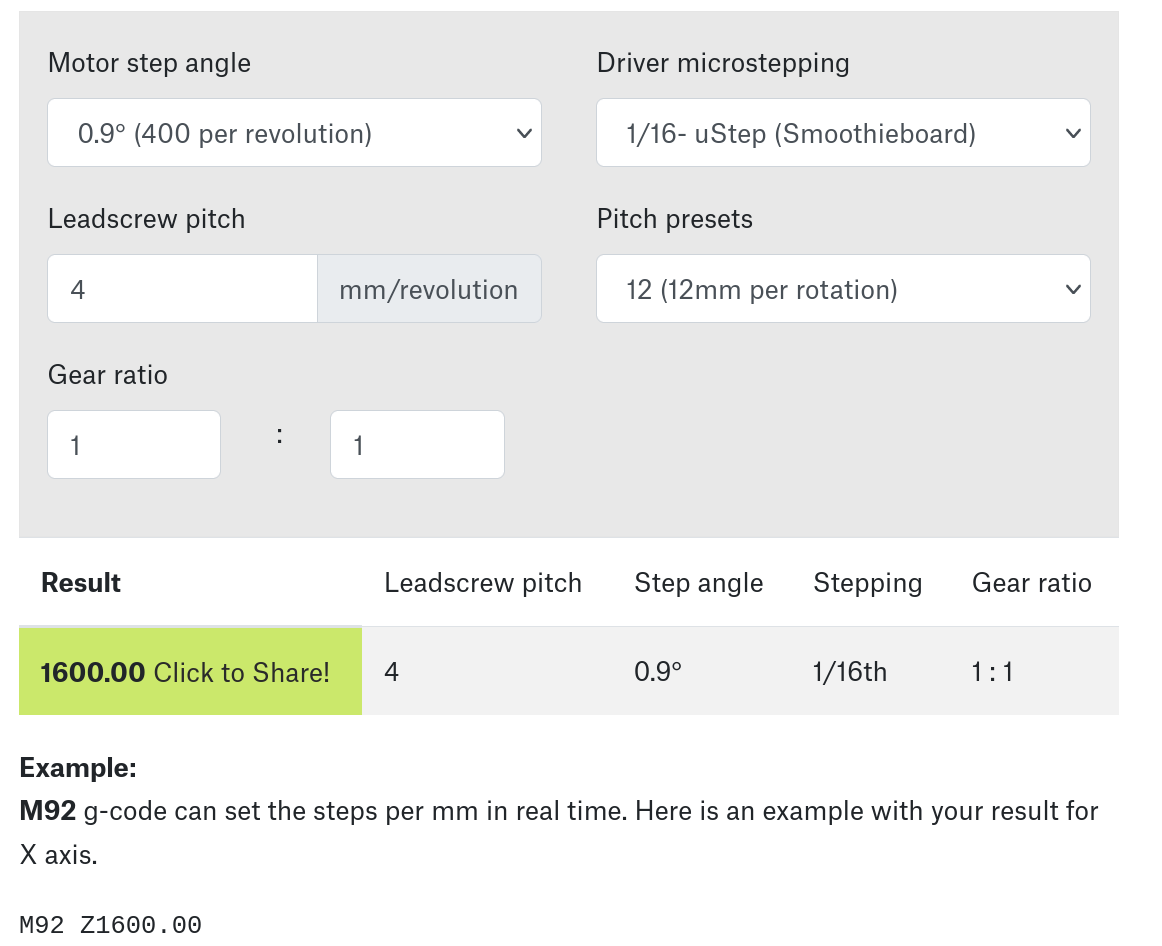

@paolozampini1973 yes, you can use the reprap calculator to calculate the right values(see https://blog.prusaprinters.org/calculator_3416/#stepspermmlead).

Note: I haven't used ballscrews nor external stepper drivers myself, but this is what I understand:

With a 1204 you put in 4mm pitch, and since you set your DM860 to 400 steps/revolution, it would look like this:

-

@oliof But I also have the dm 860h external drivers 400 steps X+ Y ENGINE 1.8

-

@oliof I want to specify that the machine that is the printer is very accurate on the Print there is an error of MAX 0.02 ALL AXIS

-

@paolozampini1973 since X and Y are driven with the same SF1204 and DM860H, the same calculation applies.

With 400 steps/revolution at full steps you would do 100 steps per millimeter so 0.01mm already. With 16x microsteps for smoothing, you would do 0.01/16 = 0.000625 mm per microstep. positional error on full steps is usually 5% (this is a stepper limitation), it can be higher on microsteps but will be within the 5% margin whenever a full step is happening. So you already have double the required precision on a full-step setup, and even within the 5% error margin there will be a lot of headspace to reach 0.02.

So the mechanical system will not limit you here. Inertia, ringing, and the behavior of the plastics during heating and cooling will be what will get you above that in practice. With high levels of part and filament specific tuning you may achieve your goal, let us know how it goes (-:

-

@oliof M350 X 16 M92 ? Yes I agree what you say Thanks Can you do the calculation please

-

@paolozampini1973 if the X axis has the same DM860, the same SF1204 and the same settings, and you set it to 16 microsteps with interpolation, then the step value in M92 will be the same as for Z. Otherwise use the reprap calculator I linked above to figure out the numbers.

-

@oliof Thanks for the support Anyway I did as you told me but I also lowered the acceleration to 1000 but I did not solve the problem As soon as I solve the problem I will let you know thanks If you have any other ideas let me know Consider that accelerations to a thousand are never Mass is very low these problems he did not give me before I meanwhile do this job and I have not been able to understand yet what the problem is

-

@paolozampini1973 if the printer is slower than expected, you can run the GCodes that limit acceleration and speed without parameters in the Console to check what they are set to.

Slicers using "Machine Limits" or "Acceleration Control" may set values that dynamically change the device speed. So it's worth checking whether that happened

-

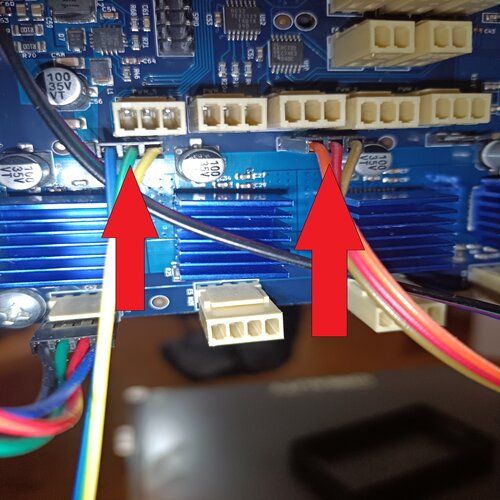

@oliof Good evening someone can tell me if taking the signal Where are the red arrows is the correct mode because I have connected the Y axis is that arrow on the left is the x axis arrow on the right you have the external drivers everything works only that it is a loss of pace and I believe the fact that the signals as I took them Maybe it's wrong Can somebody tell me if it's wrong OR is it correct thank you

-

@paolozampini1973 sorry, I am only marginally acquainted with running external stepper drivers, so I am afraid my support would be limited in reading documentation for you. I would start at https://docs.duet3d.com/en/User_manual/Connecting_hardware/Motors_connecting_external but I suggest you do it yourself so I don't add errors by misunderstanding it and misrepresenting it to you.

-

@oliof Thanks for your answer