3.3 to 3.4 on Duet2Ethernet DWC Reconnecting/crashing

-

I recently upgraded from 3.3 to 3.4 on my Duet2Ethernet (with Duex)

First thing I noticed is the MAC address for the machine changed, my DHCP IP for it went somewhere else, I found the new MAC and got the right IP assigned. This is the first time I've seen such a behavior from an upgrade, this normal?(This was resolved below)Second, I am seeing a rash of reconnections/disconnections/connection issues when working with DWC since the upgrade. During a print it will especially disconnect me and reconnect me. I am using Edge (chromium) on Win 11, and on my iPhone 13Pro with Safari, both disconnect/reconnect rapidly. Nothing changed with the network wiring or configuration of the Printer. This printer specifically runs most days and on 3.3 was flawless.

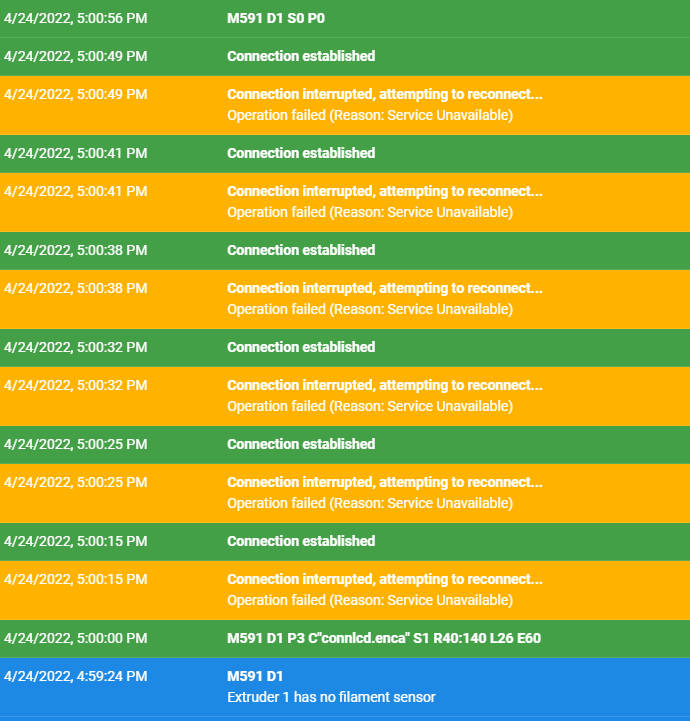

Here is an image during a run. I'll post 122 during a run to show the diag.

-

@clegg78 ```

3/21/2022, 3:16:32 PM Connection established

3/21/2022, 3:16:32 PM Connection interrupted, attempting to reconnect...

Operation failed (Reason: Service Unavailable)

3/21/2022, 3:16:13 PM Connection established

3/21/2022, 3:16:13 PM Connection interrupted, attempting to reconnect...

Operation failed (Reason: Service Unavailable)

3/21/2022, 3:16:07 PM === Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.0 (2022-03-15 18:58:31) running on Duet Ethernet 1.02 or later + DueX5

Board ID: 08DGM-917NK-F23T0-6J1F6-3SD6T-1GBWD

Used output buffers: 3 of 24 (24 max)

=== RTOS ===

Static ram: 23868

Dynamic ram: 74068 of which 0 recycled

Never used RAM 10304, free system stack 96 words

Tasks: NETWORK(ready,211.9%,196) HEAT(notifyWait,0.5%,307) Move(notifyWait,6.4%,283) DUEX(notifyWait,0.0%,24) MAIN(running,101.6%,421) IDLE(ready,0.3%,30), total 320.6%

Owned mutexes:

=== Platform ===

Last reset 04:23:41 ago, cause: power up

Last software reset at 2022-03-20 18:52, reason: User, GCodes spinning, available RAM 11924, slot 2

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x0c

Aux0 errors 0,0,0

Step timer max interval 0

MCU temperature: min 27.3, current 45.1, max 45.9

Supply voltage: min 23.8, current 23.9, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 99/1, heap memory allocated/used/recyclable 2048/144/132, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min 12

Driver 1: standstill, SG min 0

Driver 2: standstill, SG min 0

Driver 3: standstill, SG min 0

Driver 4: ok, SG min 0

Driver 5: ok, SG min 15

Driver 6: standstill, SG min 40

Driver 7: standstill, SG min 18

Driver 8: standstill, SG min n/a

Driver 9: standstill, SG min n/a

Driver 10:

Driver 11:

Date/time: 2022-03-21 15:16:03

Cache data hit count 4294967295

Slowest loop: 448.88ms; fastest: 0.12ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 8

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 6.3ms, write time 11.4ms, max retries 0

=== Move ===

DMs created 83, segments created 41, maxWait 4289859ms, bed compensation in use: mesh, comp offset 0.000

=== MainDDARing ===

Scheduled moves 943, completed 936, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 2], CDDA state 3

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

Heater 0 is on, I-accum = 0.1

Heater 2 is on, I-accum = 0.4

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== Filament sensors ===

Extruder 0: pos 322.03, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0

Extruder 1: pos 30.23, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0

=== DueX ===

Read count 1, 0.00 reads/min

=== Network ===

Slowest loop: 606.56ms; fastest: 0.02ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8

Interface state active, link 100Mbps full duplex -

https://github.com/Duet3D/RepRapFirmware/wiki/Changelog-RRF-3.x#reprapfirmware-340

[Duet 3 MB6HC in standalone mode] [Duet 3 Mini Ethernet in standalone mode] The default MAC address will change in this release. This means that your router is likely to assign it a different IP address from the previous one. If you have a DHCP address reservation for the Duet configured in your router, you will need to update it for the new MAC address.

The change log indicates that it would apply to the Duet 3, but perhaps it also effects the Duet2. I'll try to confirm.

-

How did you update to 3.4? Did you upload the full zip file? Is DWC also updated?

-

@phaedrux Yeah full zip file upload. I am tempted to try it again. And thanks for the note on the MAC change, I kind of skipped over the Duet 3 notes since this is a 2. DWC looks like its updated, looks different and says its 3.4 so I am guessing it is is updated.

You can see in the log above the "Operation failed (Reason: Service Unavailable)" is noted, that is what I have been seeing.

-

@clegg78 said in 3.3 to 3.4 on Duet2Ethernet MAC Change? DWC issues?:

"Operation failed (Reason: Service Unavailable)"

Can you share your config.g and the results of M98 P"config.g" please?

-

@phaedrux

Yeah absolutely:; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"JK3D.us IDEXRig v3.4.0" ; set printer name M929 P"eventlog.txt" S1 ; Set event log M575 P1 S1 B57600 ; Enable Panel Due Port. M555 P2 ; Set firmware compatibility to look like Marlin G21 ; Work in millimetres ; Network M552 S1 ; DHCP ;M552 P192.168.50.45 S1 ; enable network and set IP address ;M553 P255.255.255.0 ; set netmask ;M554 P192.168.50.1 ; set gateway M586 P0 S1 ; enable HTTP M586 P1 S0 ; enable FTP M586 P2 S0 ; disable Telnet ;##########Motor/Movement/Build Area############## ; Movement section M569 P0 S0; Drive 0 goes backwards(change to S0 to reverse it) -X M569 P1 S1 ; Drive 1 goes forwards ZL M569 P2 S1 ; Drive 2 goes forwards ZR M569 P3 S0 ; Drive 3 goes backwards E0 M569 P4 S1 ; Drive 4 goes forwards E1 M569 P5 S1 ; Drive 5 goes forwards U M569 P6 S1 ; Drive 6 goes backwards Y M569 P7 S0 ; Drive 7 goes forwards Y ;M569 P8 S1 ; Drive 8 goes forwards ;M569 P9 S1 ; Drive 9 goes forwards ; Motor Assignments M584 X0 Y6:7 Z1:2 U5 E3:4 ; U Axis for second X stepper, dual X and Dual Y and dualZ M350 Z16 I1; M350 X16 Y16 U16 I1; Configure microstepping with interpolation M92 X200.00 U200.00 Y200.00 Z1600 E809.00:395.2 ; set steps per mm (Updated for Hemera - 409 is stock) ; FEEDRATE CONVERSIONS ; 20mm/s = F1200 ; 70mm/s = F4200 ; 120mm/s = F7200 ;200mm/s = 12000 M201 X2000 Y2000 U2000 Z500 E7000:7000; Accelerations (mm/s^2) M203 X18000 Y18000 U18000 Z1800 E15000:15000 ; Maximum speeds (mm/min) M205 X15 Y15 U15 Z10 E50:50 ; Maximum jerk speeds mm/sec (Lowered to 13 for X and U in testing was 15 to check for skipped steps) M566 P1 ; Set Jerk Policy to 1 M204 P3000 T4000 ; Set printing and travel accelerations M906 X1200 Y1400 U1200 Z1200 E900:900 I15; Set motor currents (mA) and motor idle factor in percent (Raised X and U to 1100 for testing to overcome skippe steps) M84 S240 ; Set idle timeout ; Home to the Min of X, Max of Y, Max of U set that to get the center zero. Use the non home axis as travel limits. M208 X152.5 Y180.4 U203.59 Z300 ; Set axis maxima (adjust to suit your machine) Add U+ to move alignment to the left. M208 X-200 Y-189.5 U-152.5 Z0 S1 ; Set axis minimum (adjust to make X=0 and Y=0 the CENTER of the bed) X Changed to 200 -3mm between the X and U wit the U being 3mm further back, so add -3 to the Y number ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 U2 S1 P"e0stop" ; configure active-high endstop for High end on U via pin e0Endstop ;M574 Z2 S1 P"zstop" ; configure active-high endstop for low end on Y via pin zstop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ;Motor Stall Detection M915 X Y U F0 R2 S15 M915 Z F0 R2 S30 ;Code to calibrate the lead screws M671 X-265:265 Y0:0 S1 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis Max correction of 1 ; #######Z-Probe####### M950 S0 C"duex.pwm1" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H2.5 F70 T7500 A10 R0.5 S0.004 ; set Z probe type to bltouch and the dive height + speeds G31 P25 X16 Y28 Z1.67 ; Set Z probe trigger value (Higher the number the closer to the nozzle) Increased from 1.66 to 69 on 9/22 M557 X-145:145 Y-145:145 S48.3 ; define mesh grid M376 H8 ; Taper off compensation over 10mm of height M564 S0 ; Allow moving out of range. ; ##########Heaters/Sensors################### ;BED HEADTER M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat"T0 Q10 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S135 ; set temperature limit for heater 0 to 135C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 ;E0 ;V6 Thermistor Cartridge E0 ;M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp ;V7 Beta Thermistor E0 ;M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp ;V6 PT1000 M308 S1 P"e0temp" Y"pt1000" ; temp Sensor for V6 E0 with PT1000 M950 H1 C"e0heat" T1 Q100 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S400 ; set temperature limit for heater 1 to 400C - Copper Block,NozzleX, Ti Heatbreak, 40W Precision Heater. ; V7 300C Max temp ;M143 H1 S315 ; set temperature limit for heater 1 to 300C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ;E1 ;V6 Thermistor Cartridge E1 ;M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin e1temp ;V6 E1 PT1000 M308 S2 P"e1temp" Y"pt1000" ; temp Sensor for V6 E0 with PT1000 M950 H2 C"e1heat" T2 Q100 ; create nozzle heater output on e1heat and map it to sensor 2 ;M143 H2 S285 ; set temperature limit for heater 2 to 285C ;V7 300C Max temp M143 H2 S325 ; set temperature limit for heater 2 to 300C M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ;PT1000 calibration sensor ;M308 S8 P"duex.e5temp" Y"pt1000" A"Calibration"; sensor 8 (disabled for when not being used) ;Virtual Sensors M308 S3 P"mcu-temp" Y"mcu-temp" A"MCU" ; set virtual heater for MCU M308 S4 P"drivers" Y"drivers" A"Driver" ; set virtual heater for stepper drivers ;DHT Sensor M308 S5 P"duex.cs6" Y"dht22" A"Chamber Temp" M308 S6 P"S5.1" Y"dhthumidity" A"Chamber Humidity" ; ##########Fans############# M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 C"E0 Part Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 C"E1 Part Fan" S0 H-1 ; set fan 1 name and value. Thermostatic control is turned off M950 F2 C"fan2" Q1 ; create fan 2 on pin fan2 and set its frequency M106 P2 C"System Board Fans" S0 H3:4 T44:55 L50 X255 ; set fan 2 name and value. Thermostatic control is turned on M950 F3 C"duex.fan3" Q500 ; create fan 3 on pin duex.fan3 and set its frequency M106 P3 C"E0 HE Fan" S1 H1 T80 L0 X255 ; set fan 3 name and value. Thermostatic control is turned on M950 F4 C"duex.fan4" Q500 ; create fan 4 on pin duex.fan4 and set its frequency M106 P4 C"E1 HE Fan" S1 H2 T80 L0 X255 ; set fan 4 name and value. Thermostatic control is turned on M950 F5 C"duex.fan5" Q500 ; create fan 5 on pin duex.fan5 and set its frequency ;#####LEDS########### M106 P5 C"Pause LED" S0 H-1 ; set fan 5 name and value. Thermostatic control is turned off M950 F6 C"duex.fan6" Q500 ; create fan 6 on pin duex.fan6 and set its frequency M106 P6 C"E0 LED" S0 H-1 ; set fan 6 name and value. Thermostatic control is turned off M950 F7 C"duex.fan7" Q500 ; create fan 7 on pin duex.fan7 and set its frequency M106 P7 C"E1 LED" S0 H-1 ; set fan 7 name and value. Thermostatic control is turned off M950 F8 C"duex.fan8" Q500 ; create fan 8 on pin duex.fan8 and set its frequency ;M106 P8 C"Bed LED" S0 H-1 ; ###Commented out, no longer bed fan####set fan 8 name and value. Thermostatic control is turned off (### Going to bereplaced with chamber fan script) ;##### 24v Duex Heaters as Fan outputs ;M950 H3 C"duex.e3heat" Q500 T8 ;M141 H3 P0; Set chamber heater Not needed right now ;M106 P9 C"DummyHeater" S255 H-1 ;M950 F10 C"duex.e4heat" Q500 ;M106 P10 C"HeaterLED2" S255 H-1 ;M950 F11 C"duex.e5heat" Q500 ;M106 P11 C"HeaterLED3" S255 H-1 ;M950 F12 C"duex.e6heat" Q500 ;M106 P12 C"HeaterLED4" S255 H-1 ;############Call Chamber Fans########## M98 P"/macros/jobscripts/ChamberFan.g" ;############Call Filament Sensor Configurations######## M98 P"/macros/jobscripts/FilamentSensor.g" ;############Call Pressure Advance ######## M98 P"/macros/jobscripts/PressureAdvance.g" ;############Call InputShaping ######## M98 P"/macros/jobscripts/InputShaping.g" ;########Cold Extrusion Limit########## M302 S185 R185 ;Filament settings M404 N1.75 D0.4 ;############Extend TEMPERATURE FAULT WARNINGS - ONLY FOR Nozzle/Tool changes ;M570 H1 P90 T80 ;Heater 1 (E0) Extended Fault Warnings ;M570 H2 P90 T80 ;Heater 2 (E1) extended fault warnings ;Disable heater warnings for ;###TOOL DEFINITIONS#### ; Tool 0 X - Left hand Extruder M563 P0 D0 H1 F0 X0 S"Left Titan Aero" ; tool 0 uses extruder 0 and heater 1 and maps X to X, use fan 2 as the print cooling fan G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets ;G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ;Tool 1 U - Right hand Extruder Hemera M563 P1 D1 H2 X3 F1 S"Right Hemera" ; tool 1 uses extruder 1 and heater 2 and maps X to U, use fan 1 as the print cooling fan G10 P1 X0 Y-5.38 Z0 ; Set initial tool 1 active and standby temperatures to 0C (Higher the negative number the futher back in the Y the U axis alings) ;G10 P1 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Duplication Tool 2 M563 P2 D0:1 H1:2 X0:3 F0:1 S"Dual Duplication Print" ; tool 2 uses both extruders and hot end heaters, maps X to both X and U, and uses both print cooling fans G10 P2 X76 Y0 U-76 Z0 ; set tool offsets and temperatures for tool 2 ;G10 P2 R0 S0 M567 P2 E1:1 ; set mix ratio 100% on both extruders ; Mirror Tool 3 M563 P3 D0:1 H1:2 X0:3 F0:1 S"Dual Mirror Print" ; tool 2 uses both extruders and hot end heaters, maps X to both X and U, and uses both print cooling fans G10 P3 X85 Y0 U-85 Z0 ; set tool offsets and temperatures for tool 2 (+10mm offset for clearance due to the mirroring movements) ;G10 P3 R0 S0 M567 P3 E1:1 ; set mix ratio 100% on both extruders ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory -

@clegg78 said in 3.3 to 3.4 on Duet2Ethernet MAC Change? DWC issues?:

M929 P"eventlog.txt" S1 ; Set event log

Can you try with logging disabled? It can be quite resource intensive.

@clegg78 said in 3.3 to 3.4 on Duet2Ethernet MAC Change? DWC issues?:

MCU temperature: min 27.3, current 45.1, max 45.9

Is your board actively cooled?

-

@phaedrux Sorry I thought I replied - yes the board is actively cooled, it has a air channel with constant airflow (and thermostatically controlled fans that keep the MCU from going above 45C or so. )

I can disable the eventlog and try, not much goes in there other than the start/stop of the prints it seems.

Everything on this printer was relatively error free until 3.4.0 upgrade caused this pretty chaotic DWC stability issue. I've noticed it from multiple PCs and sometimes DWC wont even come up on mobile devices for some weird reason.

-

Update on some testing @Phaedrux @dc42

I disabled both my filament sensors for some testing (Duet Rotating magnet sensors v1.7). 2x of them.

If I enable either of them, DWC constantly reconnects. if I enable both, it gets crazy.

If both are disabled the DWC instance is stable. You can see the sequence here, the system is stable, I enable one of the sensors, and DWC starts dropping and reconnecting.

My Tool 0 sensor: M591 D0 P3 C"e1_stop" S1 R40:140 L26 E60

My Tool 1 sensor: M591 D1 P3 C"connlcd.enca" S1 R40:140 L26 E60

This is crazy repeatable as well.

-

Interesting. Would you be able to downgrade to 3.3 and see if the behaviour is definitely isolated to 3.4?

https://github.com/Duet3D/RepRapFirmware/releases/download/3.3/Duet2and3Firmware-3.3.zip

-

@phaedrux I am in the middle of a large set of production runs on the machine and I am not sure I have my 3.3 config saved (I should, but I need to find it) if I can get a gap I will test, but I had none of these issues before upgrading.

-

@clegg78 it could be that the object model has grown too large for the output buffers. Please provide your config.g file so that I can investigate this.

-

@dc42 Here is my config:

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"JK3D.us IDEXRig v3.4.0" ; set printer name M929 P"eventlog2.txt" S1 ; Set event log M575 P1 S1 B57600 ; Enable Panel Due Port. M555 P2 ; Set firmware compatibility to look like Marlin G21 ; Work in millimetres ; Network M552 S1 ; DHCP ;M552 P192.168.50.45 S1 ; enable network and set IP address ;M553 P255.255.255.0 ; set netmask ;M554 P192.168.50.1 ; set gateway M586 P0 S1 ; enable HTTP M586 P1 S0 ; enable FTP M586 P2 S0 ; disable Telnet ;##########Motor/Movement/Build Area############## ; Movement section M569 P0 S0; Drive 0 goes backwards(change to S0 to reverse it) -X M569 P1 S1 ; Drive 1 goes forwards ZL M569 P2 S1 ; Drive 2 goes forwards ZR M569 P3 S0 ; Drive 3 goes backwards E0 M569 P4 S1 ; Drive 4 goes forwards E1 M569 P5 S1 ; Drive 5 goes forwards U M569 P6 S1 ; Drive 6 goes backwards Y M569 P7 S0 ; Drive 7 goes forwards Y ;M569 P8 S1 ; Drive 8 goes forwards ;M569 P9 S1 ; Drive 9 goes forwards ; Motor Assignments M584 X0 Y6:7 Z1:2 U5 E3:4 ; U Axis for second X stepper, dual X and Dual Y and dualZ M350 Z16 I1; M350 X16 Y16 U16 I1; Configure microstepping with interpolation M92 X200.00 U200.00 Y200.00 Z1600 E809.00:395.2 ; set steps per mm (Updated for Hemera - 409 is stock) ; FEEDRATE CONVERSIONS ; 20mm/s = F1200 ; 70mm/s = F4200 ; 120mm/s = F7200 ;200mm/s = 12000 M201 X2000 Y1800 U2000 Z500 E7000:7000; Accelerations (mm/s^2) M203 X18000 Y18000 U18000 Z1800 E15000:15000 ; Maximum speeds (mm/min) M205 X15 Y13 U15 Z10 E50:50 ; Maximum jerk speeds mm/sec (Lowered to 13 for X and U in testing was 15 to check for skipped steps) M566 P1 ; Set Jerk Policy to 1 M204 P3000 T4000 ; Set printing and travel accelerations M906 X1200 Y1400 U1200 Z1200 E900:900 I15; Set motor currents (mA) and motor idle factor in percent (Raised X and U to 1100 for testing to overcome skippe steps) M84 S240 ; Set idle timeout ; Home to the Min of X, Max of Y, Max of U set that to get the center zero. Use the non home axis as travel limits. M208 X152.5 Y180.4 U203.45 Z300 ; Set axis maxima (adjust to suit your machine) Add U+ to move alignment to the left. Moved to .45 from .59 after machine warmed M208 X-200 Y-189.5 U-152.5 Z0 S1 ; Set axis minimum (adjust to make X=0 and Y=0 the CENTER of the bed) X Changed to 200 -3mm between the X and U wit the U being 3mm further back, so add -3 to the Y number ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 U2 S1 P"e0stop" ; configure active-high endstop for High end on U via pin e0Endstop ;M574 Z2 S1 P"zstop" ; configure active-high endstop for low end on Y via pin zstop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ;Motor Stall Detection M915 X Y U F0 R2 S15 M915 Z F0 R2 S30 ;Code to calibrate the lead screws M671 X-265:265 Y0:0 S1 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis Max correction of 1 ; #######Z-Probe####### M950 S0 C"duex.pwm1" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H2.5 F70 T7500 A10 R0.5 S0.004 ; set Z probe type to bltouch and the dive height + speeds G31 P25 X16 Y28 Z1.67 ; Set Z probe trigger value (Higher the number the closer to the nozzle) Increased from 1.66 to 69 on 9/22 M557 X-145:145 Y-145:145 S48.3 ; define mesh grid M376 H8 ; Taper off compensation over 10mm of height M564 S0 ; Allow moving out of range. ; ##########Heaters/Sensors################### ;BED HEADTER M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat"T0 Q10 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S135 ; set temperature limit for heater 0 to 135C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 ;E0 ;V6 Thermistor Cartridge E0 ;M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp ;V6 PT1000 M308 S1 P"e0temp" Y"pt1000" ; temp Sensor for V6 E0 with PT1000 M950 H1 C"e0heat" T1 Q100 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S400 ; set temperature limit for heater 1 to 400C - Copper Block,NozzleX, Ti Heatbreak, 40W Precision Heater. M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ;E1 ;V6 Thermistor Cartridge E1 ;M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin e1temp ;V6 E1 PT1000 M308 S2 P"e1temp" Y"pt1000" ; temp Sensor for V6 E0 with PT1000 M950 H2 C"e1heat" T2 Q100 ; create nozzle heater output on e1heat and map it to sensor 2 M143 H2 S400 ; set temperature limit for heater 2 to 400C M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ;PT1000 calibration sensor ;M308 S8 P"duex.e5temp" Y"pt1000" A"Calibration"; sensor 8 (disabled for when not being used) ;Virtual Sensors M308 S3 P"mcu-temp" Y"mcu-temp" A"MCU" ; set virtual heater for MCU M308 S4 P"drivers" Y"drivers" A"Driver" ; set virtual heater for stepper drivers ;DHT Sensor M308 S5 P"duex.cs6" Y"dht22" A"Chamber Temp" M308 S6 P"S5.1" Y"dhthumidity" A"Chamber Humidity" ; ##########Fans############# M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 C"E0 Part Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 C"E1 Part Fan" S0 H-1 ; set fan 1 name and value. Thermostatic control is turned off M950 F2 C"fan2" Q1 ; create fan 2 on pin fan2 and set its frequency M106 P2 C"System Board Fans" S0 H3:4 T44:55 L50 X255 ; set fan 2 name and value. Thermostatic control is turned on M950 F3 C"duex.fan3" Q500 ; create fan 3 on pin duex.fan3 and set its frequency M106 P3 C"E0 HE Fan" S1 H1 T80 L0 X255 ; set fan 3 name and value. Thermostatic control is turned on M950 F4 C"duex.fan4" Q500 ; create fan 4 on pin duex.fan4 and set its frequency M106 P4 C"E1 HE Fan" S1 H2 T80 L0 X255 ; set fan 4 name and value. Thermostatic control is turned on M950 F5 C"duex.fan5" Q500 ; create fan 5 on pin duex.fan5 and set its frequency ;#####LEDS########### M106 P5 C"Pause LED" S0 H-1 ; set fan 5 name and value. Thermostatic control is turned off M950 F6 C"duex.fan6" Q500 ; create fan 6 on pin duex.fan6 and set its frequency M106 P6 C"E0 LED" S0 H-1 ; set fan 6 name and value. Thermostatic control is turned off M950 F7 C"duex.fan7" Q500 ; create fan 7 on pin duex.fan7 and set its frequency M106 P7 C"E1 LED" S0 H-1 ; set fan 7 name and value. Thermostatic control is turned off M950 F8 C"duex.fan8" Q500 ; create fan 8 on pin duex.fan8 and set its frequency ;M106 P8 C"Bed LED" S0 H-1 ; ###Commented out, no longer bed fan####set fan 8 name and value. Thermostatic control is turned off (### Going to bereplaced with chamber fan script) ;##### 24v Duex Heaters as Fan outputs ;M950 H3 C"duex.e3heat" Q500 T8 ;M141 H3 P0; Set chamber heater Not needed right now ;M106 P9 C"DummyHeater" S255 H-1 ;M950 F10 C"duex.e4heat" Q500 ;M106 P10 C"HeaterLED2" S255 H-1 ;M950 F11 C"duex.e5heat" Q500 ;M106 P11 C"HeaterLED3" S255 H-1 ;M950 F12 C"duex.e6heat" Q500 ;M106 P12 C"HeaterLED4" S255 H-1 ;############Call Chamber Fans########## M98 P"/macros/jobscripts/ChamberFan.g" ;############Call Filament Sensor Configurations######## M98 P"/macros/jobscripts/FilamentSensor.g" ;############Call Pressure Advance ######## M98 P"/macros/jobscripts/PressureAdvance.g" ;############Call InputShaping ######## M98 P"/macros/jobscripts/InputShaping.g" ;########Cold Extrusion Limit########## M302 S185 R185 ;Filament settings M404 N1.75 D0.4 ;############Extend TEMPERATURE FAULT WARNINGS - ONLY FOR Nozzle/Tool changes ;M570 H1 P90 T80 ;Heater 1 (E0) Extended Fault Warnings ;M570 H2 P90 T80 ;Heater 2 (E1) extended fault warnings ;Disable heater warnings for ;###TOOL DEFINITIONS#### ; Tool 0 X - Left hand Extruder M563 P0 D0 H1 F0 X0 S"Left Titan Aero" ; tool 0 uses extruder 0 and heater 1 and maps X to X, use fan 2 as the print cooling fan G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets ;G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ;Tool 1 U - Right hand Extruder Hemera M563 P1 D1 H2 X3 F1 S"Right Hemera" ; tool 1 uses extruder 1 and heater 2 and maps X to U, use fan 1 as the print cooling fan G10 P1 X0 Y-5.38 Z0 ; Set initial tool 1 active and standby temperatures to 0C (Higher the negative number the futher back in the Y the U axis alings) ;G10 P1 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Duplication Tool 2 M563 P2 D0:1 H1:2 X0:3 F0:1 S"Dual Duplication Print" ; tool 2 uses both extruders and hot end heaters, maps X to both X and U, and uses both print cooling fans G10 P2 X76 Y0 U-76 Z0 ; set tool offsets and temperatures for tool 2 ;G10 P2 R0 S0 M567 P2 E1:1 ; set mix ratio 100% on both extruders ; Mirror Tool 3 M563 P3 D0:1 H1:2 X0:3 F0:1 S"Dual Mirror Print" ; tool 2 uses both extruders and hot end heaters, maps X to both X and U, and uses both print cooling fans G10 P3 X85 Y0 U-85 Z0 ; set tool offsets and temperatures for tool 2 (+10mm offset for clearance due to the mirroring movements) ;G10 P3 R0 S0 M567 P3 E1:1 ; set mix ratio 100% on both extruders ; Miscellaneous M501 ; load saved parameters from non-volatile memoryFilamentsensor.g:

M591 D0 P3 C"e1_stop" S1 R40:140 L26 E60 ; M591 D1 P3 C"connlcd.enca" S1 R40:140 L26 E60 ; -

@dc42 I upgraded to the 3.4.1 RC that is posted and it seems to have remedied a most of the disconnections! I am seeing the max Output buffers go to 26, but in general no (or many less) crashes or reconnections like was happening before.

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.1rc1 (2022-05-03 09:34:00) running on Duet Ethernet 1.02 or later + DueX5 Board ID: 08DGM-917NK-F23T0-6J1F6-3SD6T-1GBWD Used output buffers: 7 of 26 (26 max) === RTOS === Static ram: 23868 Dynamic ram: 74972 of which 0 recycled Never used RAM 9088, free system stack 96 words Tasks: NETWORK(ready,203.0%,218) HEAT(notifyWait,5.1%,307) Move(notifyWait,209.7%,283) DUEX(notifyWait,0.0%,24) MAIN(running,149.4%,425) IDLE(ready,0.1%,30), total 567.3% Owned mutexes: === Platform === Last reset 23:10:43 ago, cause: software Last software reset at 2022-05-14 14:04, reason: User, GCodes spinning, available RAM 9256, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x0c Aux0 errors 0,1,0 Step timer max interval 0 MCU temperature: min 42.8, current 45.7, max 46.8 Supply voltage: min 23.8, current 23.9, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/3, heap memory allocated/used/recyclable 2048/670/646, gc cycles 0 Events: 1 queued, 1 completed Driver 0: standstill, SG min 3 Driver 1: ok, SG min 0 Driver 2: ok, SG min 0 Driver 3: standstill, SG min 0 Driver 4: ok, SG min 0 Driver 5: ok, SG min 37 Driver 6: ok, SG min 9 Driver 7: ok, SG min 10 Driver 8: standstill, SG min n/a Driver 9: standstill, SG min n/a Driver 10: Driver 11: Date/time: 2022-05-15 13:15:30 Cache data hit count 4294967295 Slowest loop: 350.13ms; fastest: 0.14ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 8 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 22.2ms, write time 10.3ms, max retries 0 === Move === DMs created 83, segments created 54, maxWait 25947876ms, bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves 18853, completed 18813, hiccups 0, stepErrors 0, LaErrors 0, Underruns [356, 0, 0], CDDA state 3 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.0 Heater 2 is on, I-accum = 0.7 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is doing "G1 X-24.463 Y21.930 E0.0324" in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Filament sensors === Extruder 0: pos 2.11, errs: frame 1 parity 0 ovrun 0 pol 0 ovdue 0 Extruder 1: pos 328.01, errs: frame 0 parity 0 ovrun 0 pol 1 ovdue 0 === DueX === Read count 1, 0.00 reads/min === Network === Slowest loop: 161.96ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 Interface state active, link 100Mbps full duplex