I could use some help

-

@mac said in I could use some help:

@fcwilt no, they’ve always been where they are. We did have a discussion about high and low endstops, which led to setting the X and Y endstops as High in RRF.

I can change that if this visual info suggests all three endstops are in the low position.

I would prefer to do it by editing the config.g Instead of using RRF again.

Mac

Hi Mark,

I must have read some out of date information that I thought was NEW information and it just threw me for a bit.

There have been a lot of posts in this thread and I just wanted to verify that I was up to date.

Thanks for confirming that I am not losing my mind (at least not yet).

Frederick

-

@fcwilt you're very welcome. I was hoping to see a video link?

On the end-stops, should all of my endstops be low in rrf?

re: coding them low versus using rrf, can you comment?

Mac

-

@mac said in I could use some help:

@fcwilt you're very welcome. I was hoping to see a video link?

On the end-stops, should all of my endstops be low in rrf?

re: coding them low versus using rrf, can you comment?

Mac

Hi Mark,

Chores took up most of yesterday, the guests arrive today and I still have two things yet to do.

The endstops are physically fine where they are and the configuration is correct if you have changed the wiring from the NO pin to the NC pin.

Frederick

-

@fcwilt cool, enjoy your guests, Amazon is telling me the motors will arrive today.

-

@mac said in I could use some help:

@fcwilt cool, enjoy your guests, Amazon is telling me the motors will arrive today.

That is good news.

I hope their installation goes smoothly.

Frederick

-

@fcwilt installation? You mean I have to install them?????

-

@droftarts as Ian might say, and then he’d send a link to the documentation.

-

@fcwilt but I have read them.

-

Just thought I’d share this with you:

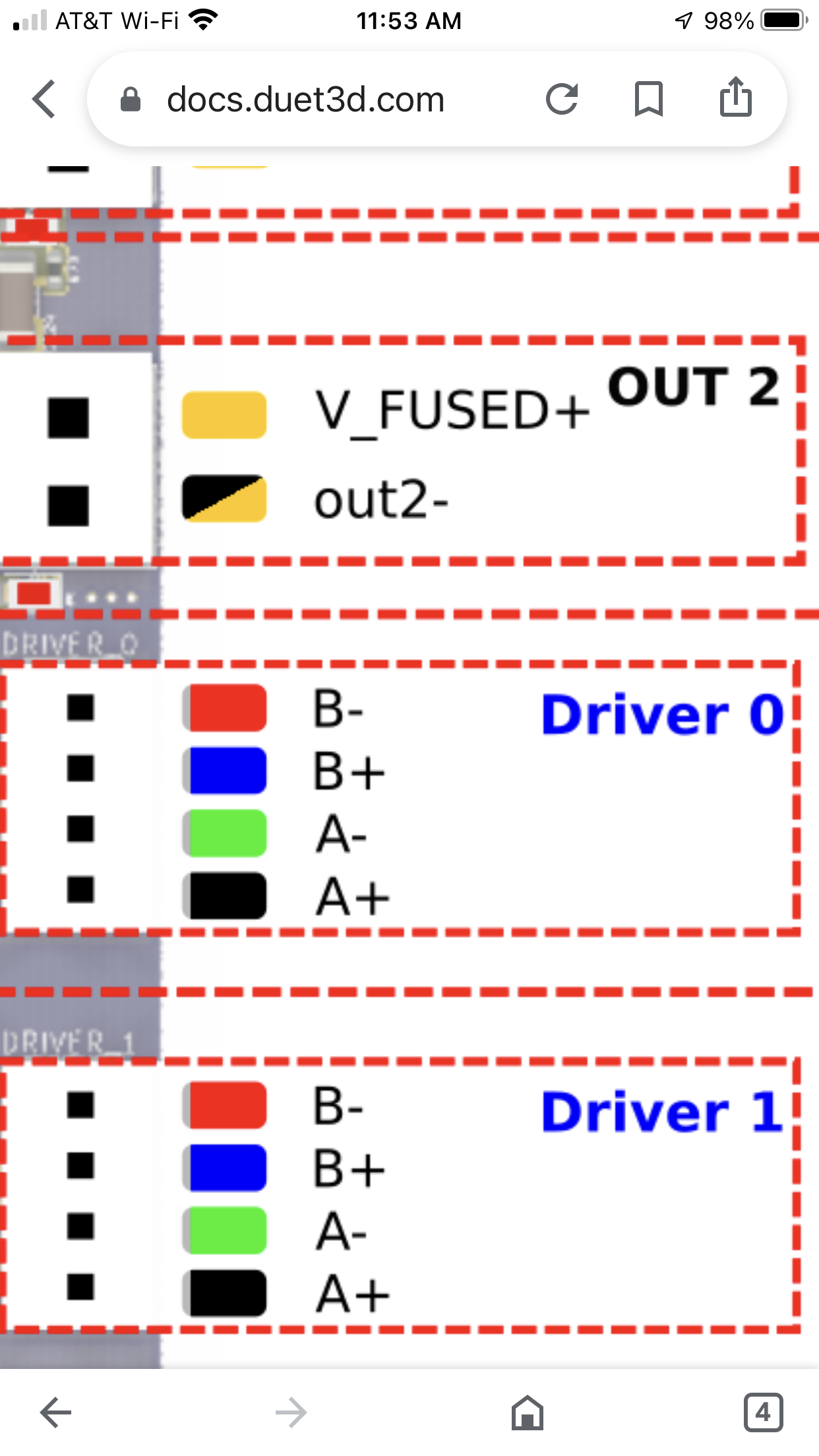

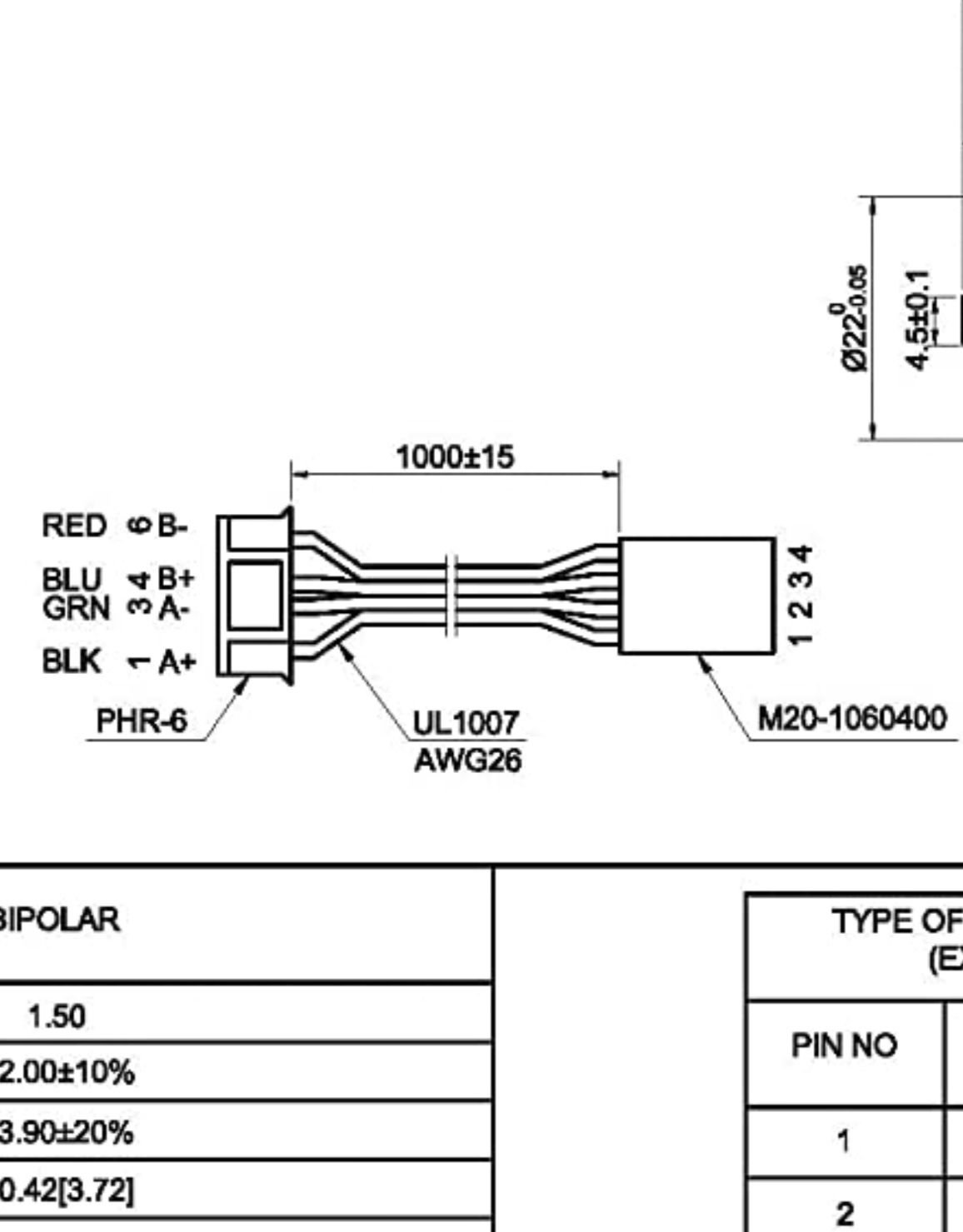

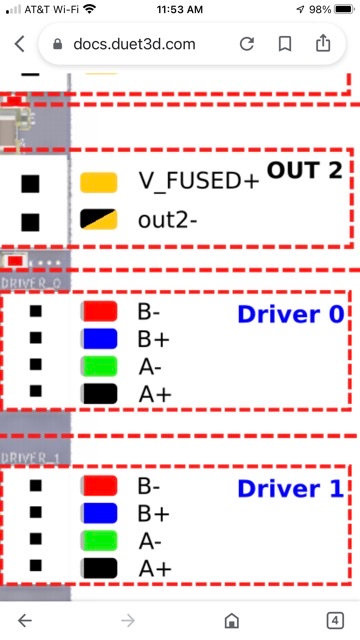

This is how the board of the Duet3D Mini 5+ is set up:

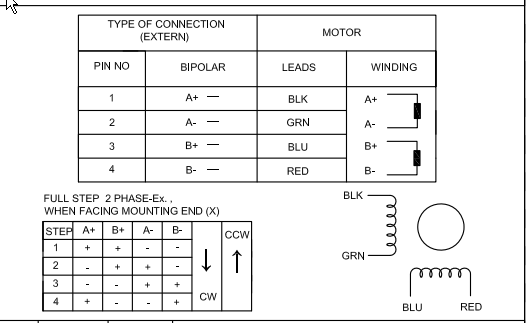

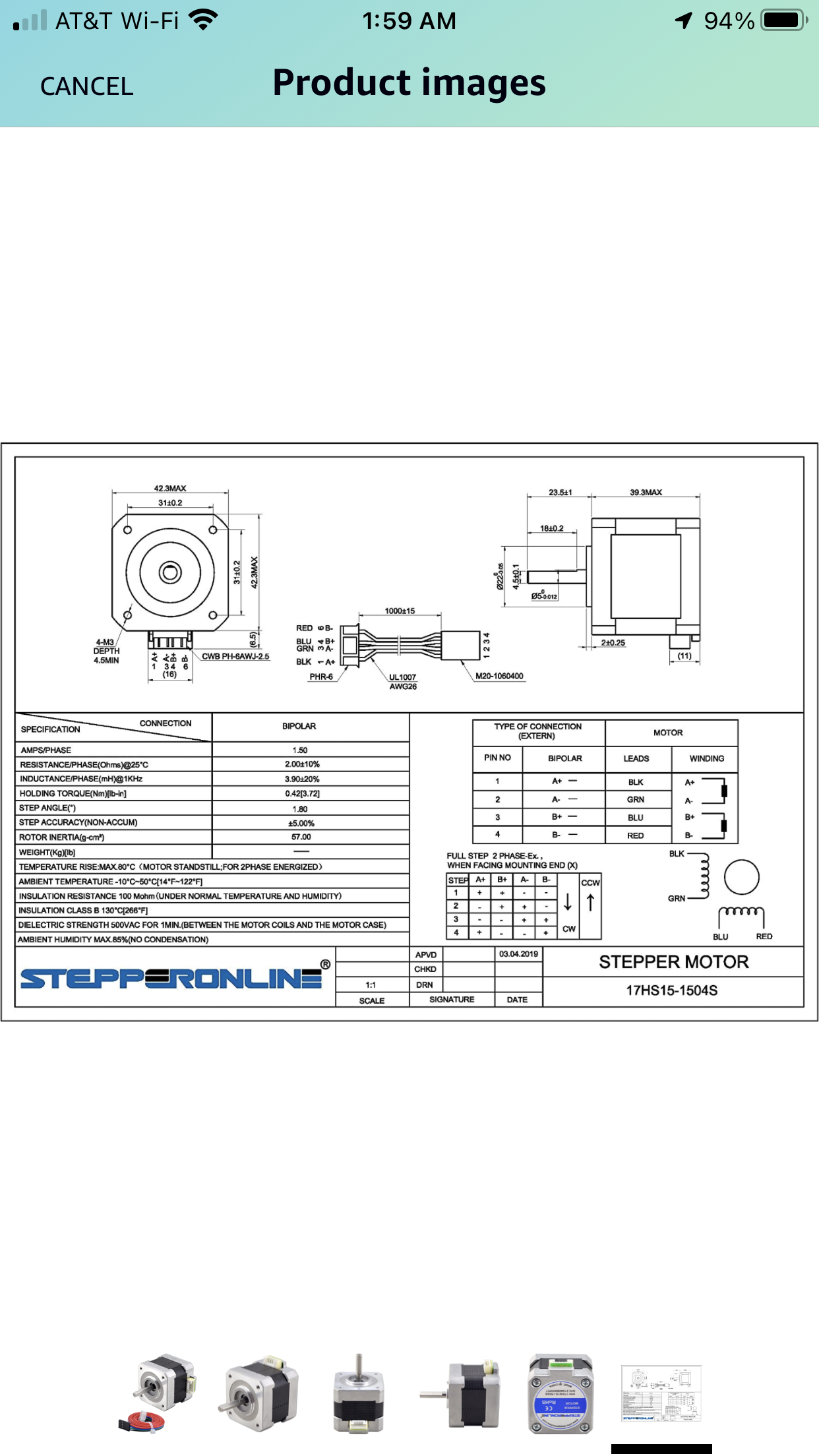

And this is how the motors I hope to install today are set up:

Talk about harmonious!

Mac

-

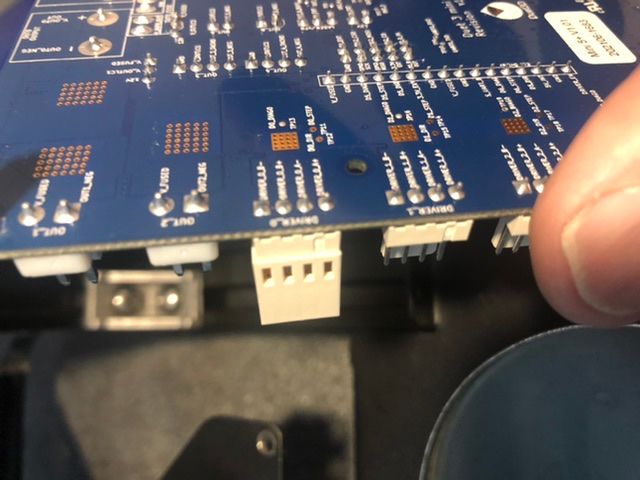

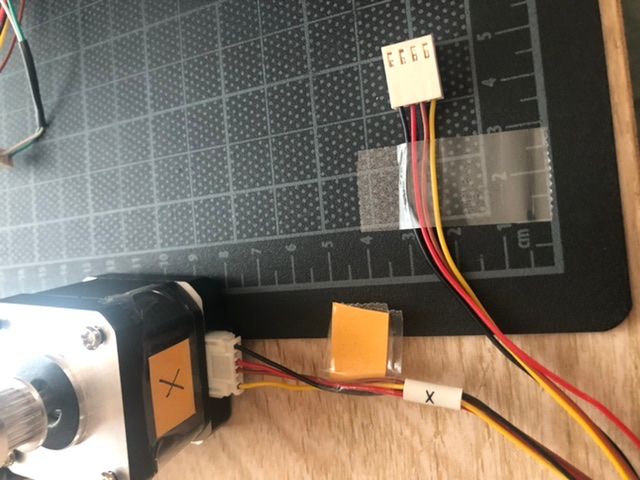

Here’s a series a pictures I’d like to share with you. They tell a story. I hope you’ll figure it out.

-

@fcwilt @droftarts Do you see what I did wrong? With all 4 motors?

Mac

-

@mac said in I could use some help:

@fcwilt @droftarts Do you see what I did wrong? With all 4 motors?

Mac

No I don't.

Based on the diagram you posted the yellow/brown pair are connecting to one phase of the stepper and the red/black pair are connecting to the other phase.

And the connections to the Duet seem correct.

What do you think is wrong?

Frederick

-

@fcwilt this is why I’m not an electrical engineer. I decided to try shorting the two phases to make sure my “discovery” was correct. As you have indicated, post’s 1 and 3 (bottom and 3rd up) are a phase, and post’s 2 and 4 are the other phase. So that means red and yellow go together, and brown and black go together. Whew, my head is spinning!

Thanks for commenting. Your affirmation is helping, a lot.

Mac

-

@mac said in I could use some help:

@fcwilt this is why I’m not an electrical engineer. I decided to try shorting the two phases to make sure my “discovery” was correct. As you have indicated, post’s 1 and 3 (bottom and 3rd up) are a phase, and post’s 2 and 4 are the other phase. So that means red and yellow go together, and brown and black go together. Whew, my head is spinning!

Thanks for commenting. Your affirmation is helping, a lot.

Mac

On the Stepper and the Duet A+ and A- are one phase, B+ and B- are the other phase.

Frederick

-

@fcwilt it’s hard for me to understand this because what I always see is A+, A-, B+, B-. I don’t know which wire of each phase is minus, or plus for that matter. That’s what’s hanging me up on this issue. If it doesn’t water, (I’ve heard that), why is the wiring of the motors presented that way? Why does Duet3D label their pins that way? You know?

-

@mac said in I could use some help:

@fcwilt it’s hard for me to understand this because what I always see is A+, A-, B+, B-. I don’t know which wire of each phase is minus, or plus for that matter. That’s what’s hanging me up on this issue. If it doesn’t water, (I’ve heard that), why is the wiring of the motors presented that way? Why does Duet3D label their pins that way? You know?

Here is a fairly typical stepper diagram showing how applied signals translate into steps:

Down on the lower left, notice the chart that has STEP 1,2,3,4 in the left column.

Notice that for Step 1 the + and - symbols under the columns for A+, B+, A- and B-.

That tells you when you apply a positive voltage to A+ and B+ and the corresponding negative voltage to A- and B- the stepper will move to Step 1.

As the board changes the voltages applied to the coils, so they match the chart, the stepper will move from Step 1 to Step 2 to Step 3 to Step 4.

And while it may not be obvious if the polarity applied to one of the coils happens to be the opposite of what the chart calls for the only thing that happens is the stepper turns in the reverse direction.

So, as long as you connect the A terminals for the Duet to the one of the coils and the B terminals of the Duet to other coil you can control the direction of rotation with the S parameter of the M569 commands.

Frederick

-

@fcwilt it truly is a magic borne of human ingenuity.

The motors didn’t show up today. Bummer. I’m hope for mail on Sunday now.

So could you talk about 24volts versus 12 volts. I know the change would cost me, but what are the hardcore benefits?

Mac

-

@mac said in I could use some help:

@fcwilt it truly is a magic borne of human ingenuity.

The motors didn’t show up today. Bummer. I’m hope for mail on Sunday now.

So could you talk about 24volts versus 12 volts. I know the change would cost me, but what are the hardcore benefits?

Mac

I already addressed that question in my post of 30th June. Scroll up and read the last bit again. Essentially you could get more torque out of the motors and use more powerful heaters. But if 12V gives you enough torque and enough heater power for your printer, you'll not see any benefit.

-

@fcwilt the motors arrived at 8:55 PM.

What, exactly, does RRF want to know about these motors?

What line of the config.g file needs to be edited, and how should it appear with the correct info?

Mac

-

@mac Motor current is all. A good setting is about 85% of the rating. So around 1.2 to 1.3 amps (1200 to 1300 mA) for those motors which are rated at 1.5Amps.