Duet mini 5+ freezes and shuts off heaters

-

Possible back pressure issue. This filament may have a higher density than normal and require less extrusion.

-

I dropped extrusion down by 80%, retested print and failed.

Removed 0.4mm nozzle and added 0.6mm nozzle. Print successful. -

@Michael-Hathaway Extract from the Polymaker data sheet for their Polymide PA6-CF........ Quote...........

"Feeding system. PA6-CF is a very stiff filament so it is required to have a good set up to ensure good feeding. For example we recommend avoiding excessive bending in the filament guide system"

.......end of quote. I don't know if any of that is pertinent in your case.

What some other people have done when feeding form large reels is to use two extruders in a push-pull arrangement. The first one can have a powerful motor to pull the filament off the reel, the second can be "normal" size. Again, I don't know if that's a viable option for your set up. If you do decide to give it a go, you define the tool to use both extruders (e.g. D0:1) and set the mixing ratio to 1.00:1.00.

-

@deckingman I have actually solved this issue using large diameter ptfe tubing, there is zero drag now.

The issue seems to be forcing it through a small nozzle. I have a successful print with a 0.6mm nozzle, I will need to adjust the feed rate down in order to minimize the back pressure causing the reset.

-

@Michael-Hathaway said in Duet mini 5+ freezes and shuts off heaters:

@deckingman I have actually solved this issue using large diameter ptfe tubing, there is zero drag now.

The issue seems to be forcing it through a small nozzle. I have a successful print with a 0.6mm nozzle, I will need to adjust the feed rate down in order to minimize the back pressure causing the reset.

Ahh OK. Also for info, the data sheet I have from Polymaker has the following recommendations for a 0.4mm nozzle. Nozzle Temp 280 -300, Bed Temp 25 -50, Chamber Temp 25 to 50 with a note not to exceed 50 deg C for either the bed or chamber (no idea why they say that). Print speed 60mm/sec. Cooling Fan OFF.

I don't have any 0.4mm nozzles - only 0.5 and upwards and I've printed PA6-CF without any issues using 0.5mm (must be wear resistant nozzle of course). Then again, I'm not using a Duet mini - Just 6HCs as both main and expansion.

Further unrelated information - ref the hygroscopic nature ........ "if the filament has absorbed moisture, it can be dried at 80 deg C for 12 hours in a convection oven". Ref getting full advantage of the thermal and mechanical properties of printed objects, "anneal parts by putting them in an oven at 90 deg C for 2 hours".

-

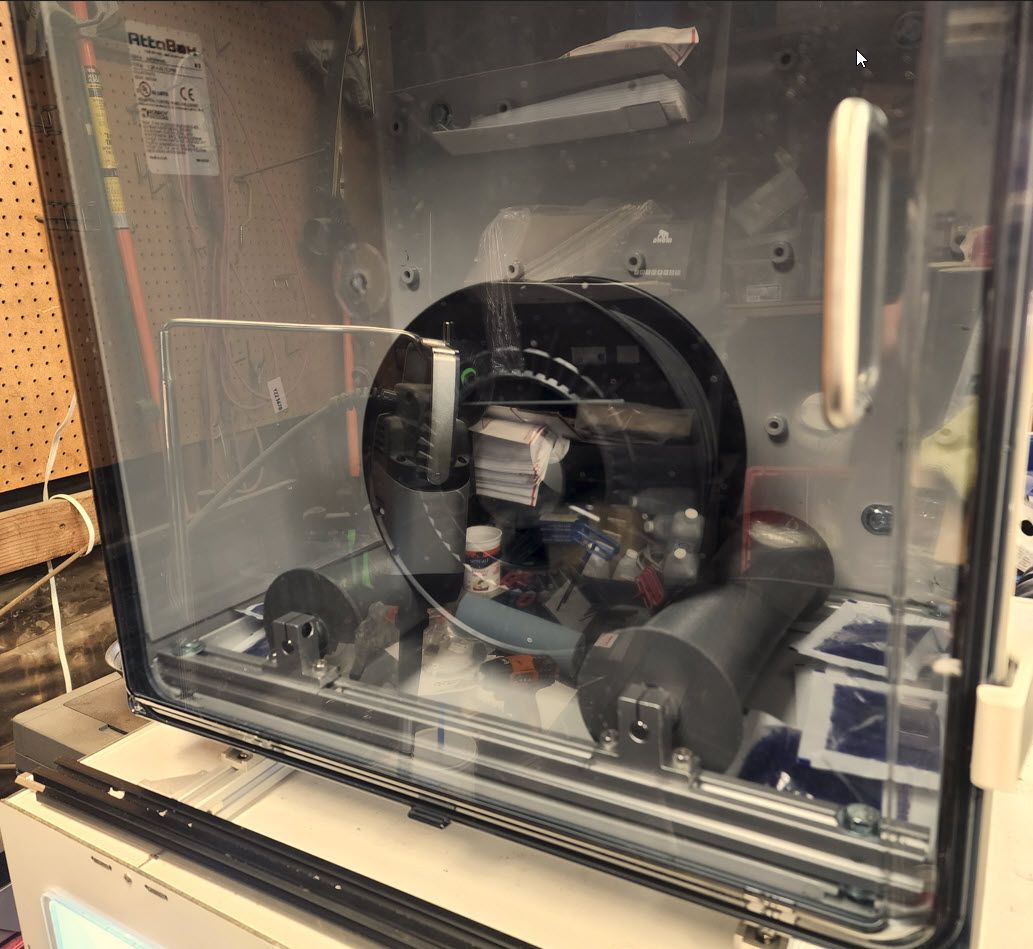

I went from concentric rollers to a center roller. This and the large tubing made the resistance nearly zero.

I am running the filament at 330C and 95C on the bed. I have a 0.5mm nozzle I can try also.

I have this one Duet mini board. All my other printers are Duet 6HC.As for dehydrating the filament, my routine is 7 days in the laboratory oven @ 90C and then into poly sealed bags and barrel storage. Then 8 hours in the oven prior to printing. The sealed container above keeps the RH at about 10%.

-

@deckingman Thank you for your input, really appreciated. I have been struggling with this for too long lol.

-

@Michael-Hathaway said in Duet mini 5+ freezes and shuts off heaters:

@deckingman Thank you for your input, really appreciated. I have been struggling with this for too long lol.

I don't think I've been much help - just supplying some more data points (and I haven't read the entire thread). It's curious that the mini5 has this issue. Given that Polymaker state not to exceed 50 deg for the bed and chamber for their PA6-CF (they don't give an explanation for this), I wonder if you reduce the bed temperature, if that would reduce the chamber temperature and help with your problem?

-

@deckingman Chamber temperature is not the problem. It wouldn't print with all the doors open. And the bed temp does not effect the chamber temperature as much as the hotend. The parts will not adhere to my Garolite at 50C and I normally run the bed at 106C.

The Duet mini must have lower settings for stepper loads which are triggering the reset. I wish I could adjust these higher. They seem too sensitive to me.

-

@Michael-Hathaway ah, OK - I guess I should have read the entire thread. It's curious that the board resets but without any driver error messages, yet the problem seems to be related to extruder driver load and is not (ambient) temperature related. It's also curious that it's extruder drivers and not one of the axis motors which one would normally expect to see higher loads. Perhaps it's somehow related to extruders running higher steps per mm than axis motors? Dunno - just idle speculation on my part. I guess the only people who could throw any light on this would be @dc42 or one of the other Duet guys.

-

@deckingman Yes, would much rather be able to adjust the parameters which are sensitive to the resets. If I lower the steps per millimeter, I run the risk of under extrusion. I manufacture automotive parts which are designed around a 0.4mm nozzle. Printing with a larger diameter nozzle would require altering the parts. And I can manually extrude from a 0.4mm nozzle at far greater speeds than those while printing, without any jamming or over driving the stepper. It is only while running a print program is there an issue.

The programming is open source, but I don't know where to make such changes. Help with this would be greatly appreciated.

-

@Michael-Hathaway Understood. But I wonder if you reduced the microstepping from say 16X to 8X for the extruder, if that would actually lead to a noticeable degredation in quality? Assuming you have a 3:1 geared extruder with around 400 steps per mm at 16X, then you,d still have 200 steps per mm at 8X which is still fairly fine grained control. Regardless of quality, it might be a useful exercise, just to see if it makes any difference to your problem. It might be another data point for the Duet guys, whether it helps or not. On the other hand, it might just be a waste of filament and PA6-CF isn't cheap.

If I get chance, I'll get hold of an 0.4mm nozzle and try a print on my machine using PA6-CF with that. I use two 6HCs, one as a main board and one as an expansion board driving the extruders. I've never had any problems like those that you are experiencing but I've never used a nozzle less that 0.5mm. -

@Michael-Hathaway said in Duet mini 5+ freezes and shuts off heaters:

The Duet mini must have lower settings for stepper loads which are triggering the reset. I wish I could adjust these higher. They seem too sensitive to me.

The only way in which the Duet 3 Mini responds to stepper loads is if you have stall detection enabled. You can set the stall detection threshold using M915.

Increased stepper loads will cause the board to draw more current, although it's hard to see how that could cause a reset, unless it causes the power supply voltage to drop.

In case noise is somehow being transferred to the reset line, you could connect a resistor with value e.g. 1K between the reset pin on the 12864 display socket and +3.3V.

-

I can confirm that stall detection is not enabled. However, it is responding to an overload. If I slow the extrusion down, it does not send a reset. But in doing so, I have under extrusion on my print.

I will try to install a 1K ohm resistor between the reset pin and +3.3V.

[edit] There is no voltage drop from the 350W or the 600W power supplies I tested.

-

A friend of mine from the Modix engineering team (who is also scratching his head over this issue), suggested adding the 1HCL expansion board just for the extruder. That way I could run the extruder at 1600-2100ma and just force the filament through the 0.4mm nozzle. The board sells for $88 dollars US and seems a tad bit extreme to solve this problem.

-

@Michael-Hathaway I agree, the EXP1HCL board is overkill in this situation.

I still think the most likely explanation is static discharge. Have you verified with a multimeter that there is continuity between the hot end metal work and a ground terminal on the Duet? Likewise, continuity between the extruder motor body and a ground terminal on the Duet?

Did you try adding the resistor?

-

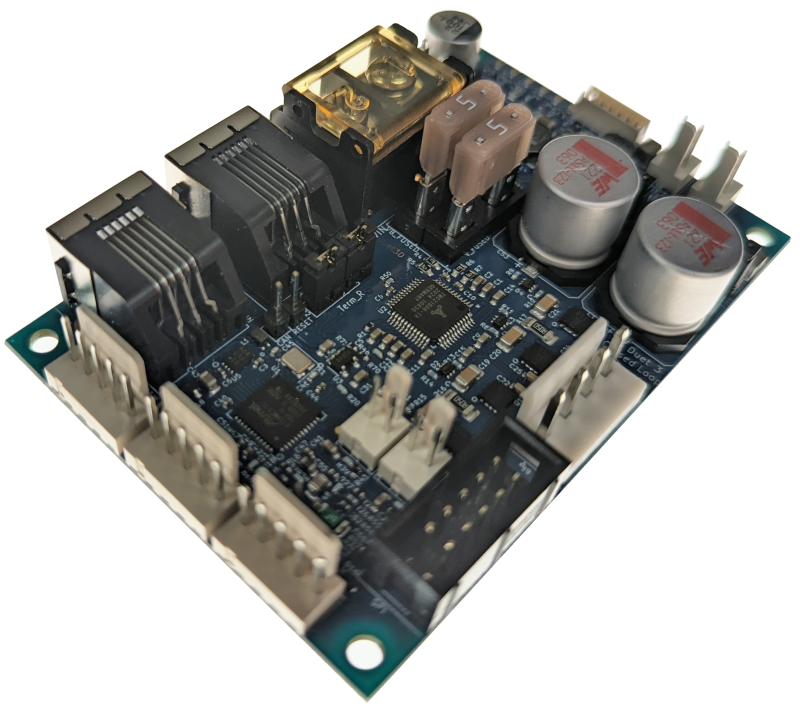

PS - I just checked the schematic. The microcontroller Reset signal is connected to the reset button, the 6-pin JST ZH programming connector next to it, pin 3 of the 12864_EXP3 connector, resistors R47 and R48, and capacitor C115. Are you certain that none of those components is touching anything, especially the pins of those two through-hole connectors on the underside of the board?

I am not aware of any mechanism whereby the processor can report that the last startup was due to the reset signal when it was actually caused by something else - except that static discharge can cause the processor to malfunction in numerous ways.

It's a long shot; but have you tried using driver 4 to drive the extruder motor instead of driver 3?

-

@dc42

I have confirmed continuity between hotend, extruder, D frame, Duet mini ground, power supply housing, power supply ground and earth ground.I have not tried resistor yet. I had to switch back to normal filament to fulfill an auto parts order. When complete, I will go back to testing.

"Reset signal is connected to the reset button, the 6-pin JST ZH programming connector next to it, pin 3 of the 12864_EXP3 connector, resistors R47 and R48, and capacitor C115. Are you certain that none of those components is touching anything, especially the pins of those two through-hole connectors on the underside of the board?"

Positively sure. The case is petg, the mount screws are isolated with nylon washers, the board is semi-loose, floating, not binding in anyway.

"It's a long shot; but have you tried using driver 4 to drive the extruder motor instead of driver 3?"

I can try this, however, I have the same problem across 3 different mini boards, my last one is brand new overnight shipped from Filastruder. So the issue is not related to a single board, but all of the boards I have tested.

One other thing I can try is enabling stall detection and cranking it to the maximum.

Most filaments will just grind at the extruder when there is a clog or restriction. But this particular High temperature nylon mixed with carbon fiber is solid, it doesn't grind.

I guess I could clamp down an extruder motor with vise grips and run a test print. If it resets, I will know there is some sort of stall detection set by default. I will watch for a voltage dip while doing this experiment.

Also, I want to thank you for your help with getting to the bottom of this.

-

My original resets were recorded as "cause: reset button". All resets currently are "Software reset"

-

@Michael-Hathaway said in Duet mini 5+ freezes and shuts off heaters:

My original resets were recorded as "cause: reset button". All resets currently are "Software reset"

In that case, please run M122 after the reset and post the result here.

Do you have the USB port connected to anything? Or any other connections to other equipment that is not powered by the Duet, not counting the Ethernet cable?