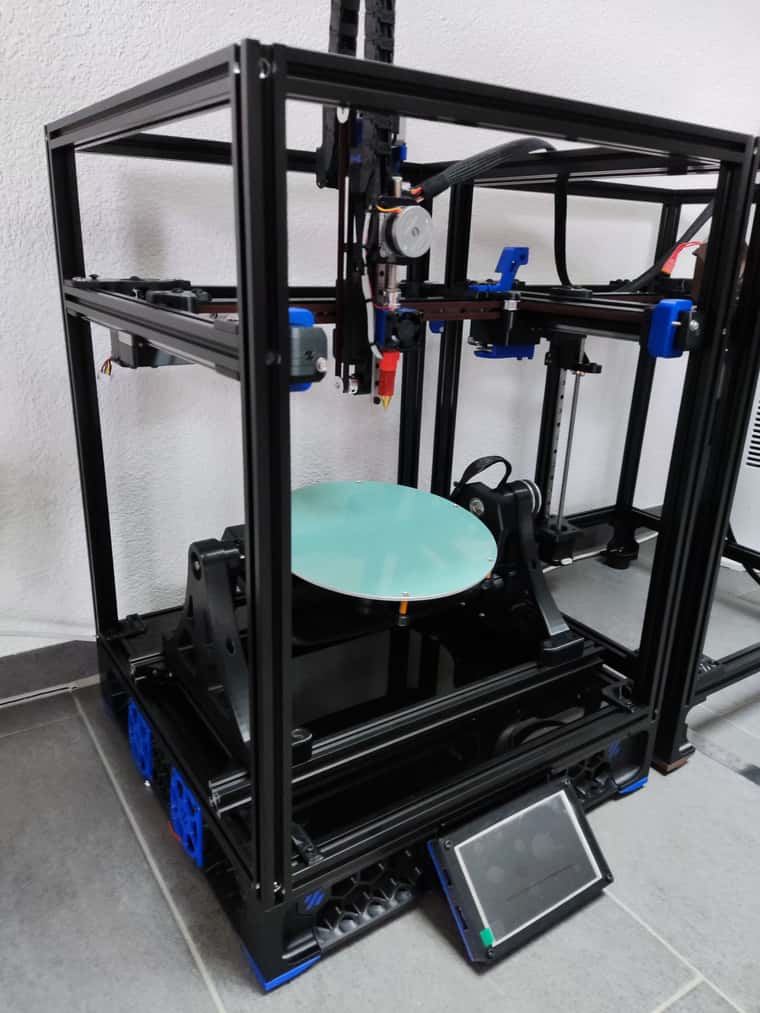

5axis Voron Trident mod with Duet6hc

-

Hello Everybody

I recently build a 5 axis conversion of open source printer Voron Trident 250 as a base and designed the 5 axis module with new printhead what is also Z axis.

Project 5 axis Voron Trident.pdf

If you would like to see it in a movement and indicator clock testing here is my

YouTube channel

https://www.youtube.com/channel/UCL7oZxzQpKNU-jJnElbkT3wNow I am already testing some full 5 axis printing still work in a progress

-

@Mafco77

Hi, the rotary base looks really sturdy and well designed.

But the z-axis looks quite wobbly and top-heavy. The x-beam is only 2020 extrusion?

I guess, you've chosen that z-design because you ran out of stepper drivers?If you encounter problems, you could go for a beefier x-beam and two linear rails. Even better would be a second passive gantry on the top frame coupled to the driven gantry with an 'anti racking' wire mod.

-

@o_lampe Thank you for your email.

To the consideration of the z axis,

the trident has very sturdy xycore mechanisms and whole hotend with extruder and z axis weight about 611g.

Also with 5 axis movement there will be no need for rapid movement of X and y axis.

When I tested printing with normal 3 axis slicer it may look wobbly but the prints came out nice.

I am using in this way the 6hc board with a full potential with stepper motors.

When I have been designing the hotend from mainly used parts what I had lying around so that is the result of it.

But in the future if the problem become with the stability, is already on my mind to design a new version of the z axis mechanism with two linear rails and lead screw for the z axis stepper motor and maybe liquid cooling for the hotend.

The main goal is to make the hotend available for maximum movement and reach around the rotary bed.