1HCL assisted open loop

-

Hey everyone,

What tuning/configuring do you need to do for the assisted open loop function? Do you need to still do the PID tuning each motor?

Cheers

Sam -

@samlogan87 we still need to document assisted open loop mode, however it needs little or no tuning. The I and D terms are not used. P should be set to about 200. V and A can be left as zero, however you may be able to get higher acceleration before steps are lost if you use a nonzero A term.

To see the effects of these terms, use the closed loop plug with a custom GCode command such as this:

G91 G1 H2 X40 F10000 G4 P50 G1 H2 X-40

By default the standstill motor current is set to 25% of the configured current, but you can change that using the M569.1 H parameter.

-

@dc42 Would it be possible to skip tuning or to perform mirrored tuning in this mode? I'm wondering as I have a rigid machine with a motor driving each side of the gantry.

Thanks -

@dc42 cool thank you. Will have a play. Finally got it running in closed loop last night and did a print, which came out quite nice.

Are you going to put something up about the V and A parameters and tuning them?

-

@dc42 One other thing, do you still need to do the positioning calibration with the assisted open loop

-

@samlogan87 said in 1HCL assisted open loop:

@dc42 One other thing, do you still need to do the positioning calibration with the assisted open loop

You need to do the calibration listed in row 1 or 2 of the table at https://docs.duet3d.com/en/User_manual/Tuning/Duet_3_1HCL_tuning#calibration.

-

@dc42 ok so all I need to do is change the homing files so that after they do the positioning move, they go into assisted open loop instead of closed?

-

@samlogan87 said in 1HCL assisted open loop:

@dc42 ok so all I need to do is change the homing files so that after they do the positioning move, they go into assisted open loop instead of closed?

Yes.

The full closed loop mode is also quieter than with previous firmware versions.

-

@dc42 yeah it definitely is. I was printing with it last night before playing with the assisted open loop.

When do you think you will put some documentation up regarding the acceleration and velocity parameters?

-

@samlogan87 here's a guide to how I do tuning for closed loop mode:

- Use a custom tuning move in the closed loop plugin. I use this or similar: G91 G1 H2 X40 F15000 G1 H2 X-40

- Set data collection to about 1000 samples/sec. 500 samples will cover the above move.

- Make sure that the print head is in a suitable place. The move I use returns to the original position so that I can run it repeatedly.

- Adjust the V and A terms to get the P term closer to zero on average. This applies to full closed loop mode only, not to assisted open loop mode.

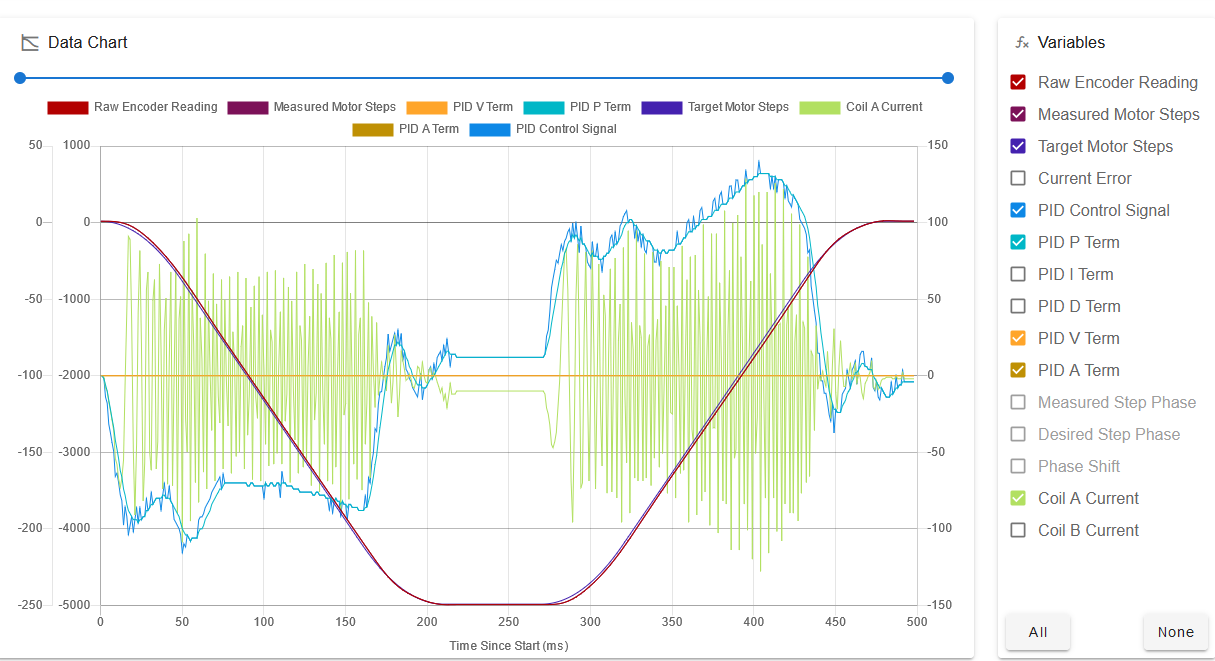

Here's a plot from the plugin with A0 V0 on my test system:

The PID control signal is almost entirely made up of the P term (the only other term present is D), which of course means there has to be a significant error present to generate the control signal.

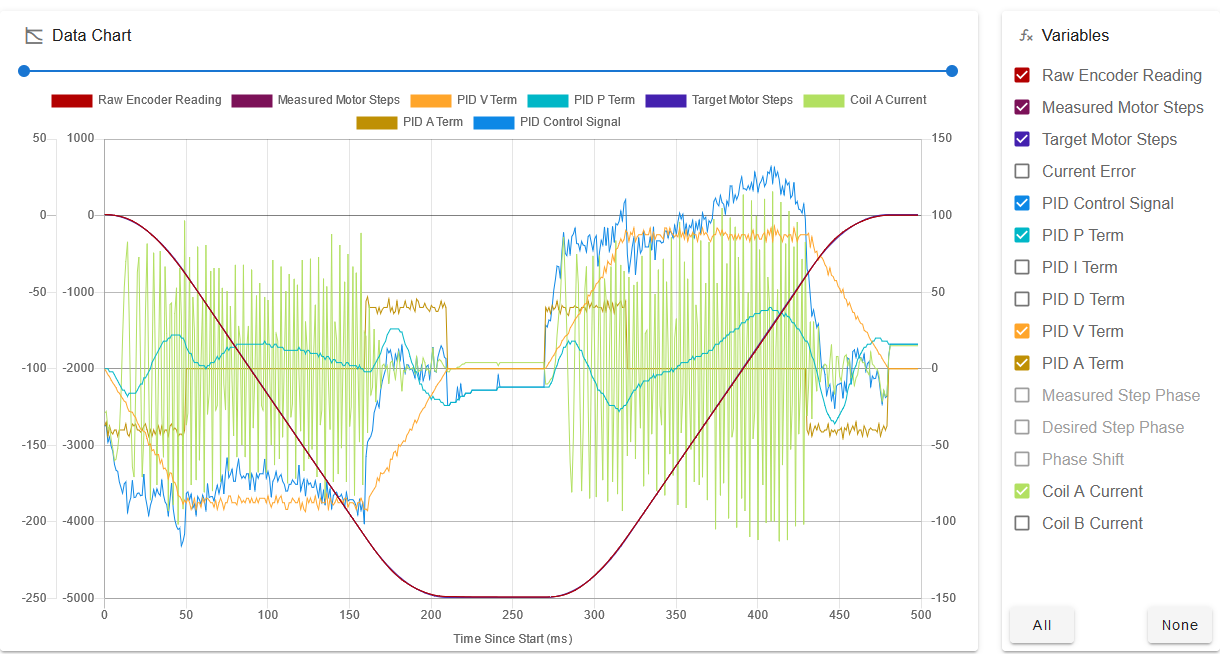

Here's a plot from the plugin with A200000 V700:

You can see that the A and V terms are doing most of the work, with the P term doing the fine tuning. The peak error (difference between measured and target motor steps) has reduced from about 3 to about 1 full step. To see the error more clearly, enable the display of Current Error and disable the display of Measured and Target Motor Steps so that the scale expands.

You can use the D term to supress oscillations in the P term, but if you make D too high then the motor noise may become unpleasant. In both plots I had P40 D0.1. Acceleration in M201 was set to 5000. I get similar results if I increase acceleration to 10000 but then the mechanics sounds clunky.