Pinpointing heater fault

-

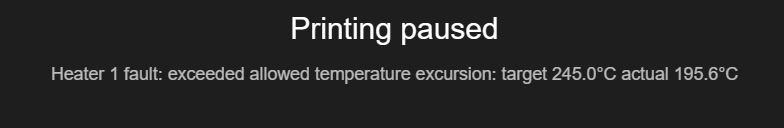

@kungpaoshizi first we need to know what type of heater fault it was. There should be a message printed to the console of DWC when the heater fault occurs, saying which type is it.

-

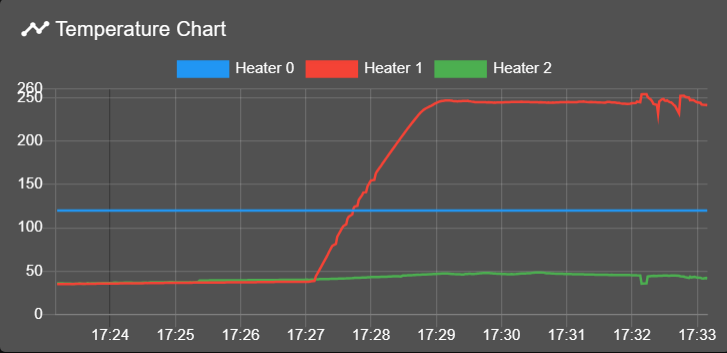

@dc42 Well now it successfully heated... I'll try a few more prints, iirc it was 'can't heat up to this temp'.. You can see the wobble in the graph

Otherwise it's not the firmware, I started having this issue on 1.21 or whatever it was. Was hoping it was a bug so new firmware looked promising...

Seems after going down that path it's still presenting randomly. This is after a pid tune as well. I've got an enclosure with all fans off, so it's not some random wind.

I'll follow up later, thanks so much DC42! Been awhile since I've been on the site I hope all is well!! -

This post is deleted! -

@dc42

Here ya go

-

@kungpaoshizi, based on the temperature graph and my past experience, you are looking at a defective thermistor or a bad connection in the thermistor wiring. The dips are too erratic to be related to the heater.

-

@jens55 Right, you would think the heater would just cut out or runaway.

Though like I said, it's 2 thermistors, both all of a sudden started doing this on both of my extruders. With both firmware all the way back in the 1 versions up to the new 3's.

It was operating perfect for the last idk, 5 years?

So I'm afraid it's the board or psu. Both out of warranty too

Both the psu and the board never go above 36-38c as I have fans dedicated to each... -

@kungpaoshizi, I would think a bad connection is more likely than a board failure and based on the graph, this is not a PSU failure.

In the way of a relevant example: I have occasional failures. I have had two issues with dud thermistors that showed erratic behaviour during the heat-up phase while working perfectly fine once operating temperature is reached. I currently have an issue that is almost certainly a poor connection even though the actual failure location has eluded me so far. I will likely cut out and replace a connector in the thermistor wiring. The failure is either a bad crimp connection (4 possibilities) or a poor connection between male and female ends of the connector. Surprisingly, wiggling the connection will not cause a reliable sensor failure - it is really odd. -

@jens55 Two different sensors have faulty wiring at the same time?

I guess it's possible something could be pinched, I'll have to check it out.@dc42 Is there any diagnostic you can think of that might aid in this scenario? Since it's gone down I have felt an emptiness inside I've not felt in years!

-

@kungpaoshizi, in my case I have two wires for the temperature sensor going from the Duet to the printer carriage. There is a connector at the carriage that lets me replace a sensor without taking the wiring harness apart. It is that connection that seems suspect in my system. Of course if you go straight from the sensor to the Duet with no additional connectors in between then that would not apply. In my case I can replace the sensor and still have the same issue because the faulty connection is not replaced with a new sensor.

Not only that but because I moved stuff around, the new sensor might work for a while and, when it's most inconvenient, will throw a hissy fit .... frustrating as hell ....

.... frustrating as hell .... -

@jens55 I grouped all my wiring together, it's all tacked down, then leading to the carriage I used a multi-rubber band overhead crane setup, to guide the wiring taking great care to eliminate any sharp angles.

I've worked with pc's too long lol

But to have both fail around the same time, could be parts failing, but I haven't used extruder 1 for 80% of the time the machine has been up. So everything on that side should be pretty fresh on the MTBF timeline.

@dc42 is there a repair service if I pinpoint it to the board? It's a meanwell psu, which I may have taxed at the high end running a lot of prints at 120/245, but it's not out of the realm of possibility. My other psu is a generic 350 which wouldn't push that I don't think. Trying to recall what my upgraded bed wattage was, which indeed doesn't route through the board, I'll have to collect all the details.

Still hoping you might have a wonderful gcode tidbit that will give me some sort of 'power range from psu vs power range from individual outputs'.. -

@kungpaoshizi said in Pinpointing heater fault:

is there a repair service if I pinpoint it to the board?

Why focus on the least plausible candidate? Your Duet is fine, else, your temperature chart would look different. @jens55 is right in saying that 'you are looking at a defective thermistor or a bad connection in the thermistor wiring.'

Interestingly, the graph hints at problems with both heaters (or their thermistors, or the wiring): look at the rectangular pulses short after 17:32. This could indicate some interference with other signals in your cabling.

To pinpoint the fault, you first should throw two loose wires at your printer: a direct connection from the thermistor to the Duet, distant from your harness. If you keep the connector near the thermistor, this one is the next thing to bridge. As @jens55 said, these are common suspects. If these measures do not help, replace the thermistor(s) as well.

-

@infiniteloop Actually you did just reinforce it's the board. The bed heater didn't show that hiccup and it's directly connected via offload relay to the psu.

The 2nd heater wasn't on, but clearly has some sort of hiccup of the relay.Again, you're trying to tell me that 2 different wires, have an issue all of a sudden at the same time, while all of the other 10-20 wires bundled with it don't have an issue, and I've taken great care to prevent long-term movement-breakage of these wires.

You realize the probability of that? It's not very realistic.

I'll have to tear it apart, but I'm afraid it's seen it's day

-

I’ve taken great care to prevent long-term movement-breakage of these wires.

I appreciate that. That’s why I never mentioned a broken wire as a possible cause of the problem. Instead, we talk about bad crimps, unreliable connectors and a potentially failing thermistor. All this results in irregular temperature readings like in your graph.

you're trying to tell me that 2 different wires, have an issue all of a sudden at the same time, while all of the other 10-20 wires bundled with it don't have an issue

Sure, and I tried to deliver an explanation: interference or overtalking. In fact, we talk of 3-4 wires (including GND) carrying a weak analog signal. Lines for heaters and steppers transfer strong pulses which can induce interferences into lines running in parallel.

The bed heater didn't show that hiccup

So what? Different crimps, different connectors, different wiring harness.

I'll have to tear it apart, but I'm afraid it's seen it's day

Prior to that, try to find the cause of the problem. As I said: two loose wires (I.e. distant to your existing wiring harness), maybe a new thermistor…

-

@infiniteloop Thanks for the input! Again it's been operating forever just fine, well passed useful dates most likely, so the probability of the board finally giving out under such heavy use over the years is way more likely than the 2 wires breaking at the same time, or 2 separate crimps at the same time, etc.

Any other suggestions from others?

Hoping dc responds with a magic diag code... Though I'm afraid the graph spells it out

Replacing the psu would be so much easier..