Melting insulation, random restarts, and thermal warnings

-

Hello,

Long time Duet 2 owner. I've got a recent issue that has cropped up after upgrading to 96ozin 2.1A Nema 17 sized steppers.

I'm getting random restarts, though strangely never in the middle of a job, where the DWC will disconnect and the Duet is clearly restarting, coming back un homed and lost WCS origins. For instance it most often occurs when I perform some sort of function other than move a stepper, IE "Set X WCS", T1, M5. But if it does happen on a G0 command the stepper never moves a single step, it just reboots.

Sometimes but not always I will see a stepper driver thermal warning in DWC as it reboots.

After noticing the thermal warning, I touched the drivers and they were at least 150 degrees Fahrenheit. I thought the MCU temp on DWC were the stepper driver temps... are they something else?

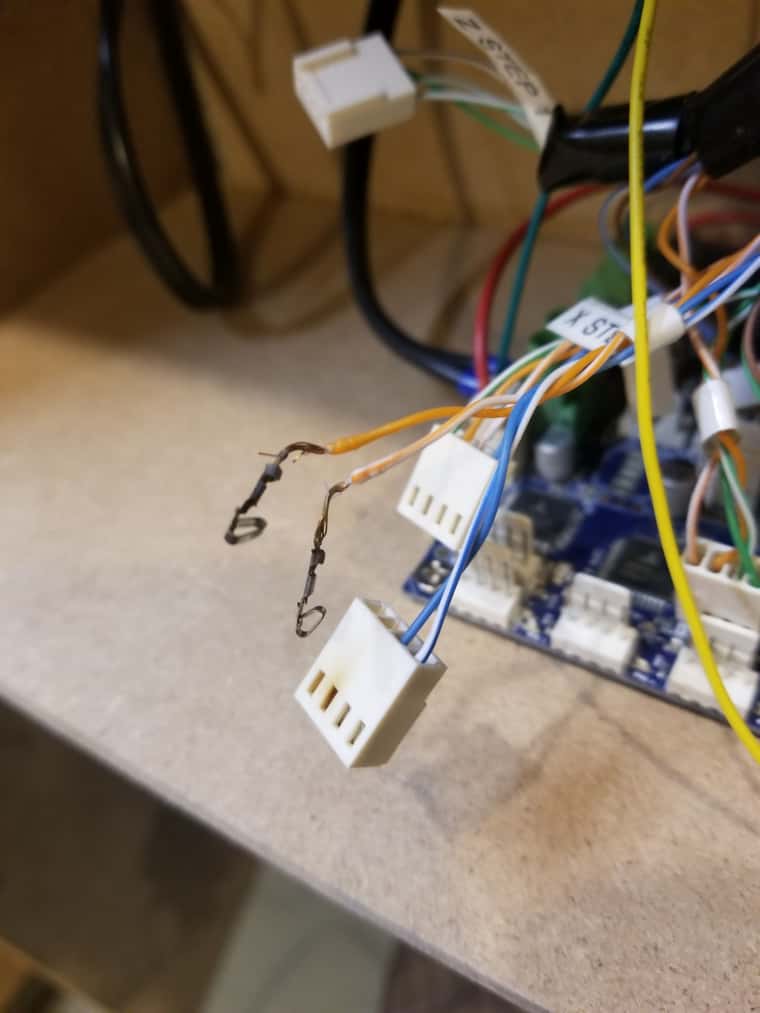

Never noticed any actual issues moving the steppers, other than the occasional lost step, anyway, got tired of it all and pulled apart the control box to see about setting up a new external closed loop stepper I bought for a different machine. That's when I noticed the X axis connector pictured below...

My config had the steppers at 1.8A IIRC

The crimps are still solid and holding strong, the insulation melted back from the insulation crimp teeth. Wire is 22 or 24 awg CAT6

I was running 24V fine with 1.5A steppers running at 1.6A previously, now with the 2.1A steppers running 24V 1.9A was causing lots and lots of restarts, I found that lowering to 16.3V (lowest my spindle relay will trigger at) and 1.8A seemed to bring the reboots down to 2-3 per 12 hrs use. I didn't know about the insulation then, or the driver thermal warnings.

I plan to check wiring resistance when I get home from work today, but was wondering if there is anything else I can check.

My other worry is that while my X was the only connector that melted, all the drivers were just as hot to the touch, and were way too hot imo. What could be going on? I fear for my board.

-

@hpiz said in Melting insulation, random restarts, and thermal warnings:

After noticing the thermal warning, I touched the drivers and they were at least 150 degrees Fahrenheit. I thought the MCU temp on DWC were the stepper driver temps... are they something else?

No, the MCU temp is for the CPU, the drivers only have thermal flags for being overtemp.

I suspect your motor wire gauge is too small for the current.

Are you actively cooling the board? 1.9A is quite high.

-

@Phaedrux I have a 140mm fan that blows into the control box, but it's not exactly pointing at the board, and probably very little air actually reaches the stepper drivers. I'll reconfigure the airflow to point directly down onto the board. I should be okay without heatsink on the chips right?

Any thoughts as to why only one stepper wiring is being melted, and only one phase? I'm obviously going to thoroughly vet the wiring on that run tonight.

I guess I dug myself into a hole without a ladder on this one. Sounds like I may have to step up to 20 or 22awg (I'm pretty sure it 24 right now). I'm sure we all look forward to stepper-rewire-day...

I wouldn't care as much but I need this machine to be able to cut the aluminum parts for my new ATC router I'm designing. Thankfully going external drivers and the 6XD on that build so it should be pretty solid.

-

I'll reconfigure the airflow to point directly down onto the board. I should be okay without heatsink on the chips right?

This is what the Duet 2 WiFi and Ethernet Hardware Overview says about Cooling. So, don't use heat sinks, provide "good airflow underneath the board" instead.

-

undefined infiniteloop referenced this topic

undefined infiniteloop referenced this topic

-

Sounds like I may have to step up to 20 or 22awg

Better use a DC wire gauge calculator - just googled this one: DC LOAD WIRING CALCULATOR. With your values and some safety margin, you will need 18-20 AWG. CAT6 is not suited for that task.

-

@hpiz @infiniteloop A convenient number to remember about the AWG scale is that a 3 gauge number decrease almost exactly doubles the area of the wire. (See https://en.wikipedia.org/wiki/American_wire_gauge). This is an ancient bit of lore, but it is pretty easy to remember, and useful for scaling wire sizes. The statement that CAT6 wire is inappropriate for running steppers is absolutely correct. Get thicker wires.

-

a 3 gauge number decrease almost exactly doubles the area of the wire.

Thx, that’s good to know. Here, I’m used to calculate cross sections in mm2, so always felt a bit lost with AWG.

-

I'm one of those crazy people, instead of buying a few proper cables, I decided to just make a whole new machine. Got Igus continuous flex 16awg for my medium current cables. Been building for a month, gonna take another 1-2 but it should be a nice upgrade.

-3.5kw ATC spindle

-400w Servo Motors (2 on Y for gantry, 1 on X)

-Dual 2510 ballscrew Y drive

-1605 ballscrews on X and Z

-400w Stepper for Z

-2ft x 4ft working areaIt's a beast.