homing problems

-

hello

So i have bumbled my way through a config file that mostly works and managed to update the firmware on my new ratrig build. I might have even learned a few things. MY machine has a few quirks that i think might be related. From the web control I can get the machine to home all successfully, but when i home all from the panel due home all fails. In an attempt to start my first print it immediately fails due to a homing failure. i hoped by homing the machine and leveling the bed prior to starting a print that it might solve this problem but i get the same result. I would love any help. Thank you!!

Config File; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"V-Core3" ; set printer name M669 K1 ; CoreXY G21 ; Set Units to Millimeters ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives ;; 1 is forward, 0 is reverse M569 P0.0 S0 ; physical drive 0.0 goes forwards M569 P0.1 S0 ; physical drive 0.1 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S1 ; physical drive 0.3 goes forwards M569 P0.4 S1 ; physical drive 0.4 goes forwards M569 P0.5 S1 ; physical drive 0.5 goes forwards M584 X0.4 Y0.3 Z0.0:0.1:0.2 E121.0 ; set drive mapping ;M584 X0.4 Y0.3 Z0.2 E122.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 ; set steps per mm M906 X1600 Y1600 Z1600 I30 ; set motor currents (mA) and motor idle factor in per cent -- safe for Duet 3 mini 5+ M84 S30 ; Set idle timeout M566 X400.00 Y400.00 Z6.00 E120.00 P1 ; set maximum instantaneous speed changes (mm/min) M203 X10800.00 Y10800.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z100.00 E3600.00 ; set accelerations (mm/s^2) ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X500 Y500 Z500 S0 ; set axis maxima ; Endstops M574 X1 S1 P"121.io2.in" ; configure active high endstops M574 Y2 S1 P"io1.in" ; configure active high endstops M671 X-4.5:250:504.5 Y-4.52:505:-4.52 S5 ; define positions of Z leadscrews or bed levelling screws M557 X20:480 Y20:480 P5 ; define 5x5 mesh grid ; Heaters M308 S0 P"temp1" Y"thermistor" T100000 B3800 A"Bed" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out5 and map it to sensor 0, lower switching frequency to 11Hz M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 110C ;; Run Bed PID Tune!! Below is an example for a 300x300 bed ;; M307 H0 A303.1 C356.7 D1.4 S1.00 V24.0 B0 ;; BtJ adding connection to Toolboard G4 S2 ; wait for expansion boards to start ;; BtJ adding connection to the PanelDue M575 P1 S1 B57600 ; Fans M950 F0 C"!121.out1+out1.tach" Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 C"Layer Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"121.out2" Q500 ; create fan 1 on pin out3 and set its frequency ;M106 P1 C"Hotend Fan" S0 H1 T45 ; set fan 1 name and value. Thermostatic control turned on for Hotend M106 P1 C"Hotend Fan" S255 H-1 ; BtJ Playing ; Tools M563 P0 D0 H1 F1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M308 S1 P"121.temp0" Y"thermistor" T100000 B3950 C7.060000e-8 A"Hotend" M950 H1 C"121.out0" T1 ; create nozzle heater output on out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S250 ; set the maximum temperature in C for heater ; EVA 2 / BMG / mosquito magnum ; M92 E830 ; set extruder steps per mm, 0.9 angle/step (LDO Pancake) ;; BtJ initial value M92 E415 ; set extruder steps per mm, 0.9 angle/step (LDO Pancake) M906 E800 ; set extruder motor current (mA) and idle factor in per cent ;; Run Heater PID Tune!! M307 H0 R0.416 K0.658:0.000 D4.26 E1.35 S1.00 B0 ; Z-Probe ;; Inductive Probe ; M558 P5 C"!io3.in" H5 F400 T5000 ; set Z probe type to unmodulated and the dive height + speeds ; G31 P500 X-30 Y-15 Z0 7.34 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ;; BLTouch M950 S0 C"121.io0.out" ; Create a servo pin on io7 M558 P9 C"121.io0.in" H5 F240 T10800 A5 ; set Z probe type to unmodulated and the dive height + speeds G31 P25 X-28.00 Y-13.00 Z2.33 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ;Select default tool ;T0 ; Pressure Advance ; M572 D0 S0.10Here Is my home all

M201 X500.00 Y500.00 ; Reduce acceleration for homing moves ; BLTouch M280 P0 S160 ; Precautionary alarm release M280 P0 S90 ; Ensure the pin is raised G91 ; Relative positioning G1 H2 Z5 F6000 ; Lift Z relative to current position G1 H1 X-625 Y605 F1800 ; Move quickly to X and Y axis endstops and stop there (first pass) G1 X3 Y-3 F600 ; Go back a few mm G1 H1 X-625 Y605 F360 ; Move slowly to X and Y axis endstops once more (second pass) G1 H1 X-625 F360 ; Move slowly to X and Y axis endstops once more (second pass) G1 H1 Y605 F360 ; Move slowly to X and Y axis endstops once more (second pass) M201 X3000 Y3000 ; Return to full acceleration G90 ; Absolute positioning ;G1 X150 Y150 F10000 ; Go to the center of the bed (300x300) ;G1 X200 Y200 F10000 ; Go to the center of the bed (400x400) G1 X250 Y250 F10000 ; Go to the center of the bed (500x500) G30 ; Home Z by probing the bed G91 ; Relative positioning G1 Z5 F100 ; Lift Z relative to current position G90 ; Absolute positioningAnd here is part of the gcode for the print.

G31 P500 X-27.8 Y-12 Z0 bl touch offset name = RatRig V-Core 3 300x300 variants = 0.4 technology = FFF family = VCORE3 bed_model = ratrig-vcore-bed-300x300.stl bed_texture = Bed-Texture-300x300.svg default_materials = Generic ABS; Generic PETG; Generic PLA [printer_model:VCORE3_400] name = RatRig V-Core 3 400x400 variants = 0.4 technology = FFF family = VCORE3 bed_model = ratrig-vcore-bed-400x400.stl bed_texture = Bed-Texture-400x400.svg default_materials = Generic ABS; Generic PETG; Generic PLA [printer_model:VCORE3_500] name = RatRig V-Core 3 500x500 variants = 0.4 technology = FFF family = VCORE3 bed_model = ratrig-vcore-bed-500x500.stl bed_texture = Bed-Texture-500x500.svg default_materials = Generic ABS; Generic PETG; Generic PLA [printer:RatRig V-Core 3 300x300] inherits = *VCORE3* bed_shape = 0x0,300x0,300x300,0x300 max_print_height = 300 printer_model = VCORE3_300 printer_variant = 0.4 [printer:RatRig V-Core 3 400x400] inherits = *VCORE3* bed_shape = 0x0,400x0,400x400,0x400 max_print_height = 400 printer_model = VCORE3_400 printer_variant = 0.4 [printer:RatRig V-Core 3 500x500] inherits = *VCORE3* bed_shape = 0x0,500x0,500x500,0x500 max_print_height = 500 printer_model = VCORE3_500 printer_variant = 0.4 [printer:*VCORE3*] cooling_tube_length = 5 cooling_tube_retraction = 91.5 default_filament_profile = default_print_profile = 0.20mm Quality @VCORE3 deretract_speed = 40 end_gcode = END_PRINT extra_loading_move = -2 extruder_offset = 0x0 gcode_flavor = marlin high_current_on_filament_swap = 0 host_type = duet machine_limits_usage = emit_to_gcode machine_max_acceleration_e = 5000 machine_max_acceleration_extruding = 9000 machine_max_acceleration_retracting = 9000 machine_max_acceleration_x = 9000 machine_max_acceleration_y = 9000 machine_max_acceleration_z = 100 machine_max_feedrate_e = 60 machine_max_feedrate_x = 500 machine_max_feedrate_y = 500 machine_max_feedrate_z = 10 machine_max_jerk_e = 5 machine_max_jerk_x = 10 machine_max_jerk_y = 10 machine_max_jerk_z = 0.4 machine_min_extruding_rate = 0 machine_min_travel_rate = 0 max_layer_height = 0.3 min_layer_height = 0.05 nozzle_diameter = 0.4 parking_pos_retraction = 92 pause_print_gcode = M601 printer_technology = FFF remaining_times = 1 retract_before_travel = 1 retract_before_wipe = 0% retract_layer_change = 1 retract_length = 1 retract_length_toolchange = 1 retract_lift = 0 retract_lift_above = 0 retract_lift_below = 0 retract_restart_extra = 0 retract_restart_extra_toolchange = 0 retract_speed = 40 silent_mode = 0 single_extruder_multi_material = 0 start_gcode = M104 S[first_layer_temperature]\nM140 S[first_layer_bed_temperature]\nSTART_PRINT EXTRUDER_TEMP=[first_layer_temperature] BED_TEMP=[first_layer_bed_temperature] use_firmware_retraction = 0 use_relative_e_distances = 0 use_volumetric_e = 0 variable_layer_height = 1 wipe = 0 z_offset = -

Can you send M122 and M98 P"config.g" in the gcode console tab of DWC and copy and paste the results here? That will give us some needed information.

Can you also check the setup page of the Panel Due and let us know the firmware version?

-

the panel due firmware is 3.5.0

m122

=== Diagnostics ===

RepRapFirmware for Duet 3 Mini 5+ version 3.4.5 (2022-11-30 19:41:16) running on Duet 3 Mini5plus WiFi (SBC mode)

Board ID: BWP0W-7196U-D65J0-40KM6-KV03Z-HD87J

Used output buffers: 1 of 40 (19 max)

=== RTOS ===

Static ram: 103652

Dynamic ram: 97972 of which 108 recycled

Never used RAM 39980, free system stack 196 words

Tasks: SBC(ready,1.2%,446) HEAT(notifyWait,0.0%,367) Move(notifyWait,0.0%,363) CanReceiv(notifyWait,0.0%,772) CanSender(notifyWait,0.0%,336) CanClock(delaying,0.0%,348) TMC(notifyWait,0.7%,106) MAIN(running,97.2%,530) IDLE(ready,0.0%,30) AIN(delaying,0.8%,263), total 100.0%

Owned mutexes: HTTP(MAIN)

=== Platform ===

Last reset 00:43:35 ago, cause: power up

Last software reset at 2023-09-12 22:08, reason: User, GCodes spinning, available RAM 39692, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task SBC Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

MCU revision 3, ADC conversions started 2615791, completed 2615790, timed out 0, errs 0

Step timer max interval 1489

MCU temperature: min 34.4, current 34.6, max 37.9

Supply voltage: min 24.0, current 24.0, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min 0, read errors 0, write errors 0, ifcnt 11, reads 6575, writes 11, timeouts 0, DMA errors 0, CC errors 0

Driver 1: standstill, SG min 0, read errors 0, write errors 0, ifcnt 11, reads 6575, writes 11, timeouts 0, DMA errors 0, CC errors 0

Driver 2: standstill, SG min 0, read errors 0, write errors 0, ifcnt 11, reads 6574, writes 11, timeouts 0, DMA errors 0, CC errors 0

Driver 3: standstill, SG min 0, read errors 0, write errors 0, ifcnt 11, reads 6574, writes 11, timeouts 0, DMA errors 0, CC errors 0

Driver 4: standstill, SG min 0, read errors 0, write errors 0, ifcnt 11, reads 6575, writes 11, timeouts 0, DMA errors 0, CC errors 0

Driver 5: not present

Driver 6: not present

Date/time: 2023-09-13 01:12:30

Cache data hit count 4294967295

Slowest loop: 3.40ms; fastest: 0.09ms

=== Storage ===

Free file entries: 10

SD card 0 not detected, interface speed: 0.0MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP* is doing "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== CAN ===

Messages queued 23492, received 52107, lost 0, boc 0

Longest wait 3ms for reply type 6026, peak Tx sync delay 258, free buffers 18 (min 17), ts 13079/13078/0

Tx timeouts 0,0,0,0,0,0

=== SBC interface ===

Transfer state: 5, failed transfers: 0, checksum errors: 0

RX/TX seq numbers: 35656/35656

SPI underruns 0, overruns 0

State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x0f1bc

Buffer RX/TX: 0/0-0, open files: 0

=== Duet Control Server ===

Duet Control Server v3.4.6

Code buffer space: 4096

Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0

Full transfers per second: 32.75, max time between full transfers: 52.3ms, max pin wait times: 30.5ms/9.0ms

Codes per second: 0.02

Maximum length of RX/TX data transfers: 3296/740

9/13/2023, 12:33:02 AM m115 b121

Duet TOOL1LC rev 1.1 or later firmware version 3.4.0 (2022-03-15 09:00:04)

9/13/2023, 12:29:36 AM m115

FIRMWARE_NAME: RepRapFirmware for Duet 3 Mini 5+ FIRMWARE_VERSION: 3.4.5 ELECTRONICS: Duet 3 Mini5plus WiFi FIRMWARE_DATE: 2022-11-30 19:41:16 -

@Phaedrux

Sorry but i don't understand the m98 command -

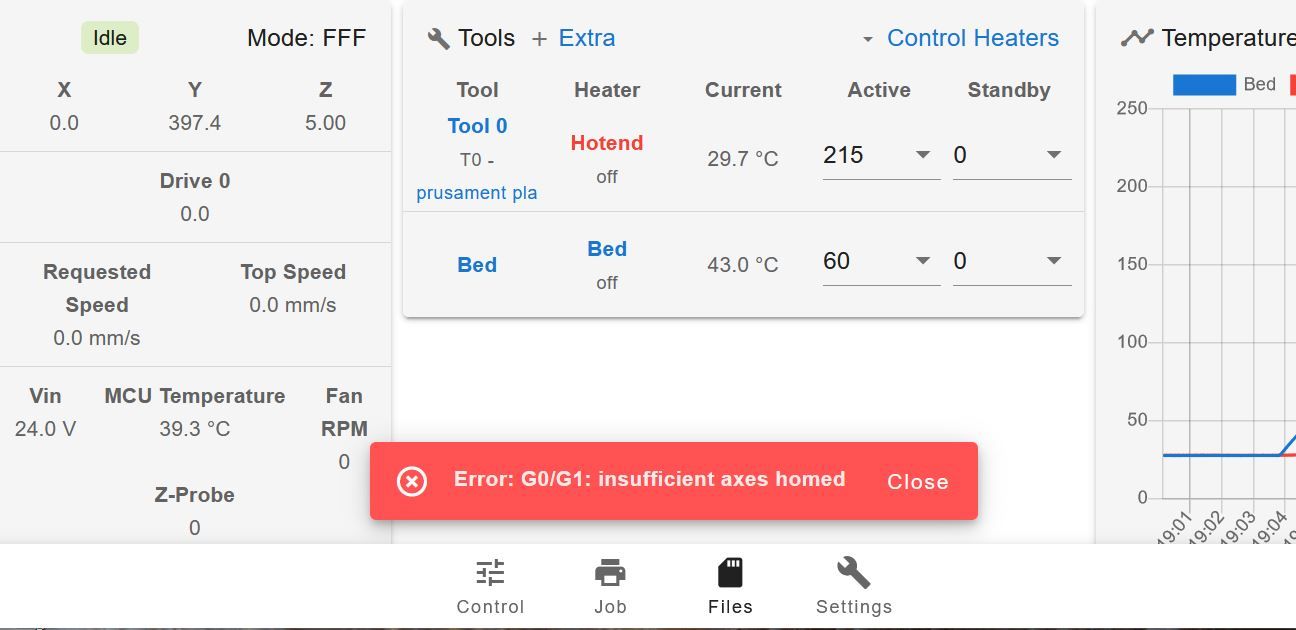

here is a screenshot of the print failure.

-

@spfxshane said in homing problems:

@Phaedrux

Sorry but i don't understand the m98 commandIn SBC mode it probably won't say much of anything unless there are configuration syntax errors.

-

Can you share the complete gcode file you're trying to print?

-

-

@spfxshane

sorry took me a minute to figure out how to send this. I was just taking a swing at slicing something in prusa slicer and get it to work on this machine. Getting information on setting up a slicer profile for this machine is defiantly been hard; and I'm just starting that journey after building the hardware and wading through the software for the machine. -

G1 H1 X-625 Y605 F1800 ; Move quickly to X and Y axis endstops and stop there (first pass) G1 X3 Y-3 F600 ; Go back a few mm G1 H1 X-625 Y605 F360 ; Move slowly to X and Y axis endstops once more (second pass) G1 H1 X-625 F360 ; Move slowly to X and Y axis endstops once more (second pass) G1 H1 Y605 F360 ; Move slowly to X and Y axis endstops once more (second pass)I think the problem is that your initial homing moves are incomplete for a corexy. You're moving both X and Y axis together, but as soon as one of the endstops is hit, the homing move ends, so one axis will be left unhomed. Then the short move to back off the endstop is throwing the error because it's trying to move an unhomed axis.

Your second pass is correct though, it moves both axis at once, then each axis individually to ensure they are both actually homed.

So if you just duplicate your second pass moves to the first pass, you'll be good to go I think.

-

That fixed it on the panel due!

I will give the print a try. I'm hopeful -

@spfxshane

success!

Now i have to figure out how to deal with the next problem. Maybe you can help point me in the right direction. Is there a way to configure one tool into the config file. this time the print failed because i did not choose a tool. The bed heated, then the machined homed, then faulted because i didn't choose a tool. I then put tool zero on standby started the print again and the bed heated and it immediately started the print with a cold extruder. i was hoping would heat theebed and then wait for the hotend to heat up and start the print. -

Uncomment

T0in your config.g to have the first tool selected at startup. Your slicer should also choose the tool before the print, but you may need to add that to your slicer start gcode.@spfxshane said in homing problems:

;Select default tool

;T0