Magnet Filament Monitor V4 - Calibration Issue

-

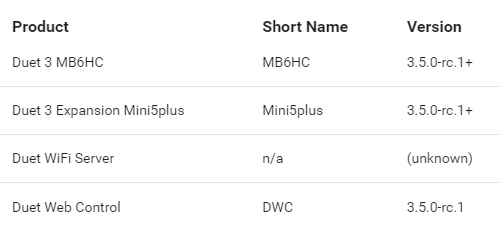

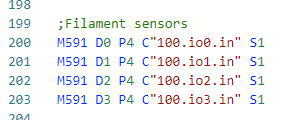

;M929 S3 ;enable debug logging ;M575 P1 S1 B57600 ;Enable PanelDue Port G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"V-Core Toolchanger" ; set printer name ; Enable network M552 P0.0.0.0 S1 M669 K1 ; select CoreXY mode G4 S2 ; wait for expansion boards to start ; Drives ;XY1: back left ;XY2: back right M569 P0.2 S0 ; stepper XY1 M569 P0.3 S0 ; stepper XY2 M569 P0.4 S1 ; stepper Coupler M569 P100.0 S0 ; stepper E0 M569 P100.1 S0 ; stepper E1 M569 P100.2 S0 ; stepper E2 M569 P100.3 S0 ; stepper E3 M569 P0.0 S0 ; stepper Z1 M569 P0.1 S0 ; stepper Z2 M569 P0.5 S0 ; stepper Z3 M569 P100.5 S1 ; wiper disk M569 P100.6 S0 ; wiper Z height M584 X0.3 Y0.2 C0.4 ; set drive mapping (motion system X Y C) M584 E100.0:100.1:100.2:100.3 ; set drive mapping (extruders) M584 Z0.0:0.1:0.5 ; set drive mapping (motion system Z) M584 W100.6 ; set drive mapping (Wiper Z height M584 D100.5 R1 ; set drive mapping (Wiper disk, rotary) ;Leadscrew order (starting back center, then clockwise): ;1: back center ;2: front right ;3: front left M671 X-12:216:-203 Y222:-179:-179 S30 ; set Z leadscrew positions ; Axis Limits if !exists(global.hasRunInit) global minY = -266 global maxY = 115 M208 X-148:160 Y{global.minY,global.maxY} ; set axis minima & maxima M208 C0:250 Z-2:270 ; set axis minima & maxima M208 W0:25 D-100000:100000 ; set axis minima & maxima, D(isk) limit can't be disabled, so it's big and additionally, the position gets reset each time when using it in the wiper macro M92 X80.00 Y80.00 ; X/Y: 1.8°/step ;M92 X160.00 Y160.00 ; X/Y: 0.9°/step M92 C200.00 ; C: E3D coupler M92 Z800.00 ; Z: 0.9 Stepper TR8x4 leadscrews M92 W800.00 D{400 * 16 / 360} ; W: 0.9 Stepper TR8x8 leadscrew, D: 0.9 Stepper with a disk M350 X16 Y16 I1 ; configure microstepping with interpolation M350 C16 Z16 I1 ; configure microstepping with interpolation M350 W16 D16 I1 M566 X600 Y600 C2 Z200 ; set maximum instantaneous speed changes (mm/min) M566 W50 D200 M203 X30000 Y30000 C10000 Z2000 ; set maximum speeds (mm/min) M203 W4000 D20000 M201 X5000 Y5000 Z500 ; set accelerations (mm/s^2) M201.1 X5000 Y5000 Z500 ; set accelerations for special moves (mm/s^2) M201 C500 ; set accelerations (mm/s^2) M201 W400 D10000 M204 P500 T5000 ;M204 P5000 T5000 M906 X2000 Y2000 ; set motor currents (mA) for X/Y M906 C700 ; set motor currents (mA) for coupler M906 Z1500 ; set motor currents (mA) for Z M906 W1000 D1400 ; set motor currents (mA) for wiper Z and disk M906 E500:500:500:500 ; set motor currents (mA) for 4x LGX M906 I50 ;only a single idle factor allowed for ALL steppers M84 S30 ; Set idle timeout ;=================== Extruder ====================== M92 E408:408:408:408 ; set steps per mm M350 E16:16:16:16 I1 ; configure microstepping M566 E500:500:500:500 ; set maximum instantaneous speed changes (mm/min) ; used to be at 1200 M203 E15000:15000:15000:15000 ; set maximum speeds (mm/min) M201 E3000:3000:3000:3000 ; set accelerations (mm/s^2) M201.1 E3000 ; set accelerations for special moves (mm/s^2) ;==================================================== ; Endstops M574 X2 S1 P"0.io0.in" ; configure active-high endstop for high end on X via pin xstop M574 Y1 S1 P"0.io1.in" ; configure active-high endstop for high end on Y via pin ystop M574 Z0 ; No Z-Endstop (use as probe instead) ; Z-Probe if !exists(global.hasRunInit) global zProbeSpeedFeed = 300 global zProbeSpeedFeedLevel = 1500 global zProbeSpeedTravel = 20000 global zProbeDiveHeightLevel = 30 global zProbeDiveHeightMesh = 3 global zProbePin = "0.io2.in" global zProbeType = 8 global zProbeTriggerValue = 200 global minXMesh = -146 global maxXMesh = 150 global minYMesh = -150 global maxYMesh = 150 global meshPointSpacing = 30 M558 K0 P{global.zProbeType} C{global.zProbePin} H{global.zProbeDiveHeightMesh} F{global.zProbeSpeedFeed} T{global.zProbeSpeedTravel} ; Z Endstop/probe M558 K2 P8 C"0.io4.in" H10 F100 T20000 ; tool length switch G31 K0 X0 Y0 Z0 P200 ;G31 K1 X0 Y0 Z0 P200 G31 K2 X0 Y0 Z0 P200 ;G31 K0 X0 Y0 Z0 P{global.zProbeTriggerValue} ; set Z probe trigger value, offset and trigger height, offsets here are hardcoded in leveling macro as well M557 X{global.minXMesh, global.maxXMesh} Y{global.minYMesh, global.maxYMesh} S{global.meshPointSpacing} ; define mesh grid M376 H30 ; Set bed correction taper ; Heaters M308 S0 P"100.temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor M950 H0 C"100.out0" T0 Q10 ; create bed heater output and map it to sensor 0 M143 H0 S121 ; set temperature limit for heater 0 to 121C M307 H0 R0.648 K0.269:0.000 D2.51 E1.35 S1.00 B0 ; Bed PID Tuning M140 H0 ; map heated bed to heater 0 M308 S1 P"0.temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor M950 H1 C"0.out1" T1 ; create nozzle heater output and map it to sensor 1 M143 H1 S301 ; set temperature limit for heater 1 to 301C M308 S2 P"0.temp2" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor M950 H2 C"0.out2" T2 ; create nozzle heater output and map it to sensor 2 M143 H2 S301 ; set temperature limit for heater 2 to 301C M308 S3 P"100.temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 3 as thermistor M950 H3 C"100.out1" T3 ; create nozzle heater output and map it to sensor 3 M143 H3 S301 ; set temperature limit for heater 3 to 301C M308 S4 P"100.temp2" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor M950 H4 C"100.out2" T4 ; create nozzle heater output and map it to sensor 2 M143 H4 S301 ; set temperature limit for heater 2 to 301C M302 S190 R190 ;Cold extrusion settings M307 H1 R2.870 K0.424:0.004 D1.67 E1.35 S1.00 B0 V23.7 ; PID Tuning T0 M307 H2 R4.192 K0.576:0.000 D1.72 E1.35 S1.00 B0 V23.7 ; PID Tuning T1 M307 H3 R4.265 K0.638:0.023 D2.27 E1.35 S1.00 B0 V23.6 ; PID Tuning T2 M307 H4 R3.767 K0.441:0.050 D2.28 E1.35 S1.00 B0 V23.5 ; PID Tuning T3 ; Fans M950 F0 C"0.out7" ; Hotend Fan Tool 0 M106 P0 S255 L255 H1 T50 C"T0 Hotend" ; Hotend Fan Tool 0 M950 F1 C"0.out4" Q50 ; Layer Fan Tool 0 M106 P1 S0 H-1 C"T0" ; Layer Fan Tool 0 M950 F2 C"0.out8" ; Hotend Fan Tool 1 M106 P2 S255 L255 H2 T50 C"T1 Hotend" ; Hotend Fan Tool 1 M950 F3 C"0.out5" Q50 ; Layer Fan Tool 1 M106 P3 S0 H-1 C"T1" ; Layer Fan Tool 1 M950 F4 C"100.out5" ; Hotend Fan Tool 2 M106 P4 S255 L255 H3 T50 C"T2 Hotend" ; Hotend Fan Tool 2 M950 F5 C"100.out3" Q50 ; Layer Fan Tool 2 M106 P5 S0 H-1 C"T2" ; Layer Fan Tool 2 M950 F6 C"100.out6" ; Hotend Fan Tool 3 M106 P6 S255 L255 H4 T50 C"T3 Hotend" ; Hotend Fan Tool 3 M950 F7 C"100.out4" Q50 ; Layer Fan Tool 3 M106 P7 S0 H-1 C"T3" ; Layer Fan Tool 3 ;Static layer fan M950 F8 C"0.out0" Q65535 ; static layer fan M106 P8 S0 H-1 I1 L0.2 C"RSCS" ; Tools M563 P0 D0 H1 F1 ; define tool 0 G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H2 F3 ; define tool 1 G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M563 P2 D2 H3 F5 ; define tool 2 G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C M563 P3 D3 H4 F7 ; define tool 3 G10 P3 R0 S0 ; set initial tool 3 active and standby temperatures to 0C M563 P4 S"Pen" ; define tool 4 (Pen) ;Dock present switches M950 J0 C"0.io7.in" ; Tool 0 Dock switch M950 J1 C"0.io8.in" ; Tool 1 Dock switch M950 J2 C"100.io5.in" ; Tool 2 Dock switch M950 J3 C"100.io6.in" ; Tool 3 Dock switch ;additional tool related switches M950 J4 C"0.io3.in" ;toolhead tool present switch ;Filament sensors M591 D0 P4 C"100.io0.in" S1 M591 D1 P4 C"100.io1.in" S1 M591 D2 P4 C"100.io2.in" S1 M591 D3 P4 C"100.io3.in" S1 M950 S0 C"0.out9" Q333 ;PebbleWiper Servo M280 P0 S70 ;Servo in idle position M950 P1 C"0.io5.out" ;Light switch PWM ;Toolhead Dotstar M950 E0 C"led" T0 ;Accelerometer M955 P0 C"spi.cs2+spi.cs3" ;Inputshaping ;M593 P"zvddd" F70 S0.2 ; Miscellaneous M98 P"/macros/ToolheadDisplay/InitToolheadDisplay" M98 P"/macros/Misc/Lights/On" M98 P"/sys/config-tools.g" M98 P"/sys/config-filaments.g" if !exists(global.hasRunInit) global deactivateToolAfterFilamentChange = false global hasRunInit = true global daemonActive = true global lastMacroResult = null -

@dc42

InitToolheadDisplay:if !exists(global.dispLEDCount) global dispLEDCount = 64 global dispDefaultBrightness = 10 global lastDisplayContent = "" global toolheadDisplayState = "" if !exists(global.RGBWhite) && boards[0].firmwareVersion != "3.4.5" ;Digits global displayDigit = vector(10, vector(8, null)) ;0 set global.displayDigit[0][0] = {0,1,1,1,1,1,1,0} set global.displayDigit[0][1] = {1,1,1,1,1,1,1,1} set global.displayDigit[0][2] = {1,1,1,0,0,1,1,1} set global.displayDigit[0][3] = {1,1,1,0,0,1,1,1} set global.displayDigit[0][4] = {1,1,1,0,0,1,1,1} set global.displayDigit[0][5] = {1,1,1,0,0,1,1,1} set global.displayDigit[0][6] = {1,1,1,1,1,1,1,1} set global.displayDigit[0][7] = {0,1,1,1,1,1,1,0} ;1 set global.displayDigit[1][0] = {0,0,1,1,1,0,0,0} set global.displayDigit[1][1] = {0,0,1,1,1,1,0,0} set global.displayDigit[1][2] = {0,0,1,1,1,1,1,0} set global.displayDigit[1][3] = {0,0,1,1,1,0,0,0} set global.displayDigit[1][4] = {0,0,1,1,1,0,0,0} set global.displayDigit[1][5] = {0,0,1,1,1,0,0,0} set global.displayDigit[1][6] = {0,0,1,1,1,0,0,0} set global.displayDigit[1][7] = {0,0,1,1,1,0,0,0} ;2 set global.displayDigit[2][0] = {0,1,1,1,1,1,1,0} set global.displayDigit[2][1] = {1,1,1,1,1,1,1,1} set global.displayDigit[2][2] = {1,1,1,0,0,1,1,1} set global.displayDigit[2][3] = {0,1,1,1,0,0,0,0} set global.displayDigit[2][4] = {0,0,0,1,1,1,0,0} set global.displayDigit[2][5] = {0,0,0,0,0,1,1,1} set global.displayDigit[2][6] = {1,1,1,1,1,1,1,1} set global.displayDigit[2][7] = {1,1,1,1,1,1,1,1} ;3 set global.displayDigit[3][0] = {0,1,1,1,1,1,1,1} set global.displayDigit[3][1] = {1,1,1,1,1,1,1,1} set global.displayDigit[3][2] = {1,1,1,0,0,0,0,0} set global.displayDigit[3][3] = {0,1,1,1,1,1,1,1} set global.displayDigit[3][4] = {0,1,1,1,1,1,1,1} set global.displayDigit[3][5] = {1,1,1,0,0,0,0,0} set global.displayDigit[3][6] = {1,1,1,1,1,1,1,1} set global.displayDigit[3][7] = {0,1,1,1,1,1,1,1} var FLF1 = {{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,1,0,1,1,0,1,0},{1,1,1,1,1,1,1,1},{0,1,0,1,1,0,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0}} var FLF2 = {{0,0,0,1,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{0,1,0,1,1,0,1,0},{1,1,1,1,1,1,1,1},{0,1,0,1,1,0,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0}} var FLF3 = {{0,0,0,1,1,0,0,0},{0,0,0,1,0,0,0,0},{0,0,0,0,0,0,0,0},{0,1,0,1,1,0,1,0},{1,1,1,1,1,1,1,1},{0,1,0,1,1,0,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0}} var FLF4 = {{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,0,0,0,0},{0,1,0,0,0,0,1,0},{1,1,1,1,1,1,1,1},{0,1,0,1,1,0,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0}} var FLF5 = {{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,1,0,1,0,0,1,0},{1,1,1,0,0,1,1,1},{0,1,0,1,1,0,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0}} var FLF6 = {{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,1,0,1,1,0,1,0},{1,1,1,1,0,1,1,1},{0,1,0,0,0,0,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0}} var FLF7 = {{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,1,0,1,1,0,1,0},{1,1,1,1,1,1,1,1},{0,1,0,1,0,0,1,0},{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0}} var FLF8 = {{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,1,0,1,1,0,1,0},{1,1,1,1,1,1,1,1},{0,1,0,1,1,0,1,0},{0,0,0,1,0,0,0,0},{0,0,0,0,0,0,0,0}} var FLF9 = {{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,1,0,1,1,0,1,0},{1,1,1,1,1,1,1,1},{0,1,0,1,1,0,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,0,0,0,0}} global filamentLoadFrames = {var.FLF1, var.FLF2, var.FLF3, var.FLF4, var.FLF5, var.FLF6, var.FLF7, var.FLF8, var.FLF9} global filamentLoadFrameIndex = 0 var HTF1 = {{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{0,0,1,1,1,1,0,0},{0,1,1,1,1,1,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0}} var HTF2 = {{0,0,0,1,1,0,0,0},{0,0,1,1,1,1,0,0},{0,1,1,1,1,1,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,0,0,0,0,0}} var HTF3 = {{0,0,1,1,1,1,0,0},{0,1,1,1,1,1,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0}} var HTF4 = {{0,1,1,1,1,1,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0}} var HTF5 = {{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{0,0,1,1,1,1,0,0}} var HTF6 = {{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{0,0,1,1,1,1,0,0},{0,1,1,1,1,1,1,0}} var HTF7 = {{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{0,0,1,1,1,1,0,0},{0,1,1,1,1,1,1,0},{0,0,0,1,1,0,0,0}} var HTF8 = {{0,0,0,1,1,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{0,0,1,1,1,1,0,0},{0,1,1,1,1,1,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0}} var HTF9 = {{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{0,0,1,1,1,1,0,0},{0,1,1,1,1,1,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0}} global heatingToolFrames = {var.HTF1, var.HTF2, var.HTF3, var.HTF4, var.HTF5, var.HTF6, var.HTF7, var.HTF8, var.HTF9} global heatingToolFrameIndex = 0 var HBF1 = {{0,0,0,1,1,0,0,0},{0,0,1,1,1,1,0,0},{0,1,1,1,1,1,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{1,1,1,1,1,1,1,1}} var HBF2 = {{0,0,1,1,1,1,0,0},{0,1,1,1,1,1,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,0,0,0,0,0},{1,1,1,1,1,1,1,1}} var HBF3 = {{0,1,1,1,1,1,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{1,1,1,1,1,1,1,1}} var HBF4 = {{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{1,1,1,1,1,1,1,1}} var HBF5 = {{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{0,0,1,1,1,1,0,0},{1,1,1,1,1,1,1,1}} var HBF6 = {{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{0,0,1,1,1,1,0,0},{0,1,1,1,1,1,1,0},{1,1,1,1,1,1,1,1}} var HBF7 = {{0,0,0,1,1,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{0,0,1,1,1,1,0,0},{0,1,1,1,1,1,1,0},{0,0,0,1,1,0,0,0},{1,1,1,1,1,1,1,1}} var HBF8 = {{0,0,0,0,0,0,0,0},{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{0,0,1,1,1,1,0,0},{0,1,1,1,1,1,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{1,1,1,1,1,1,1,1}} var HBF9 = {{0,0,0,0,0,0,0,0},{0,0,0,1,1,0,0,0},{0,0,1,1,1,1,0,0},{0,1,1,1,1,1,1,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{0,0,0,1,1,0,0,0},{1,1,1,1,1,1,1,1}} global heatingBedFrames = {var.HBF1, var.HBF2, var.HBF3, var.HBF4, var.HBF5, var.HBF6, var.HBF7, var.HBF8, var.HBF9} global heatingBedFrameIndex = 0 global RGBOff = {0,0,0,0} global RGBRed = {255,0,0,25} global RGBGreen = {0,255,0,10} global RGBBlue = {0,0,255,45} global RGBYellow = {255,255,0,30} global RGBPink = {255,20,147,10} global RGBWhite = {255,255,255,10} global ToolColors = {global.RGBRed, global.RGBGreen, global.RGBYellow, global.RGBBlue}Misc/Lights/On:

M42 P1 S230config-tools.g:

M98 P"/sys/config-tools-size.g" M98 P"/sys/config-tools-material.g" ;Z-Offset: ;If nozzle is too close to bed _reduce_ offset (negative number becomes more negative) ;If nozzle is too far away, _increase_ offset (negative number becomes less negative) M98 P"/sys/config-tools-offset.g" ;Tool offsets G10 P4 X0 Y46.5 Z-20.000 ; set tool 4 axis offsetsconfig-tools-size.g:

;nozzle sizes if !exists(global.toolNozzleSizes) global toolNozzleSizes = vector(5,0) set global.toolNozzleSizes[0] = 0.6 set global.toolNozzleSizes[1] = 0.4 set global.toolNozzleSizes[2] = 0.6 set global.toolNozzleSizes[3] = 0.6 set global.toolNozzleSizes[4] = 0.0config-tools-material.g:

;nozzle materials if !exists(global.toolNozzleMaterials) global toolNozzleMaterials = vector(5,"") set global.toolNozzleMaterials[0] = "Brass" set global.toolNozzleMaterials[1] = "Hardened" set global.toolNozzleMaterials[2] = "Brass" set global.toolNozzleMaterials[3] = "Brass HF" set global.toolNozzleMaterials[4] = ""config-tools-offset.g:

;Z-Offset: ;If nozzle is too close to bed _reduce_ offset (negative number becomes more negative) ;If nozzle is too far away, _increase_ offset (negative number becomes less negative) ;tool offsets G10 P0 X-8.300 Y39.975 Z-3.620 G10 P1 X-8.756 Y40.144 Z-3.340 G10 P2 X-8.438 Y40.700 Z-3.320 G10 P3 X-8.450 Y40.600 Z-3.460config-filaments.g:

var filaments = {"PETG - Generic","PLA - Generic","PLA - PolyTerra","PLA - Silk", "XTCF20", "PCCF - Prusament", "PLA - Wood"} if !exists(global.filamentSettings) global pebbleFeedSpeedDefault = 0 global pebbleFeedSpeed = global.pebbleFeedSpeedDefault global nozzleSizeMap = vector(6, null) set global.nozzleSizeMap[0] = 0.25 set global.nozzleSizeMap[1] = 0.4 set global.nozzleSizeMap[2] = 0.6 set global.nozzleSizeMap[3] = 0.8 set global.nozzleSizeMap[4] = 1.0 set global.nozzleSizeMap[5] = 1.2 global filamentSettings = null set global.filamentSettings = vector(#var.filaments, vector(2,null)) set global.pebbleFeedSpeedDefault = 300 set global.pebbleFeedSpeed = global.pebbleFeedSpeedDefault while iterations < #var.filaments set global.filamentSettings[iterations][0] = var.filaments[iterations] set global.filamentSettings[iterations][1] = vector(#global.nozzleSizeMap, {0.0, 0.5, 2000, 0.2, 150, global.pebbleFeedSpeedDefault}) ; default settings: PA, retraction distance, retraction speed, Z-Hop, min extrusionTemp, pebble feed speed ; PA R-Dist R-Speed Z-Hop MinTemp Pebble Speed ;PETG - Generic set global.filamentSettings[0][1][0] = {0.175, 0.5, 2100, 0.2, 200, global.pebbleFeedSpeedDefault} ;0.25 set global.filamentSettings[0][1][1] = {0.1, 0.5, 2100, 0.2, 200, global.pebbleFeedSpeedDefault} ;0.4 set global.filamentSettings[0][1][2] = {0.05, 0.7, 2500, 0.2, 200, global.pebbleFeedSpeedDefault} ;0.6 set global.filamentSettings[0][1][3] = {0.03, 0.5, 2100, 0.2, 200, global.pebbleFeedSpeedDefault} ;0.8 set global.filamentSettings[0][1][5] = {0.015, 0.5, 2100, 0.2, 200, global.pebbleFeedSpeedDefault} ;1.2 ;PLA - PolyTerra set global.filamentSettings[2][1][0] = {0.115, 0.5, 2100, 0.0, 180, global.pebbleFeedSpeedDefault} ;0.25 set global.filamentSettings[2][1][1] = {0.04, 0.5, 2100, 0.0, 180, global.pebbleFeedSpeedDefault} ;0.4 set global.filamentSettings[2][1][2] = {0.025, 0.5, 2100, 0.0, 180, global.pebbleFeedSpeedDefault} ;0.6 set global.filamentSettings[2][1][3] = {0.02, 0.5, 2100, 0.0, 180, global.pebbleFeedSpeedDefault} ;0.8 ;PLA - Silk set global.filamentSettings[3][1][0] = {0.0, 0.5, 2100, 0.0, 180, global.pebbleFeedSpeedDefault} ;0.25 set global.filamentSettings[3][1][1] = {0.055, 0.5, 2100, 0.0, 180, global.pebbleFeedSpeedDefault} ;0.4 set global.filamentSettings[3][1][2] = {0.0, 0.5, 2100, 0.0, 180, global.pebbleFeedSpeedDefault} ;0.6 set global.filamentSettings[3][1][3] = {0.0, 0.5, 2100, 0.0, 180, global.pebbleFeedSpeedDefault} ;0.8 ;XTCF20 set global.filamentSettings[4][1][2] = {0.05, 0.5, 2100, 0.0, 180, global.pebbleFeedSpeedDefault * 0.5} ;0.6 ;PCCF - Prusament set global.filamentSettings[5][1][2] = {0.04, 0.3, 3000, 0.0, 260, global.pebbleFeedSpeedDefault * 0.5} ;0.6 ;PLA - Wood set global.filamentSettings[6][1][2] = {0.04, 0.3, 3000, 0.2, 180, global.pebbleFeedSpeedDefault} ;0.6 -

Im basically seeing this same behavior with other monitors. Once the Monitor is qureried with an

M591 D0It will repeat the same value for the rest of the print. It will however trigger an error and pause the printer if I go over and interfear with the feed.7/19/2023, 6:58:47 PM M591 D0 Pulse-type filament monitor on pin 124.io0.in, enabled, sensitivity 0.156mm/pulse, allowed movement 75% to 120%, check every 2.4mm, measured sensitivity 0.162mm/pulse, measured minimum 86%, maximum 109% over 949.8mm 7/19/2023, 5:49:24 PM M591 D0 Pulse-type filament monitor on pin 124.io0.in, enabled, sensitivity 0.156mm/pulse, allowed movement 75% to 120%, check every 2.4mm, measured sensitivity 0.162mm/pulse, measured minimum 86%, maximum 109% over 949.8mm 7/19/2023, 3:42:30 PM M591 D0 Pulse-type filament monitor on pin 124.io0.in, enabled, sensitivity 0.156mm/pulse, allowed movement 75% to 120%, check every 2.4mm, measured sensitivity 0.162mm/pulse, measured minimum 86%, maximum 109% over 949.8mmas you can see I've polled the monitor over a good sampling of time durring a print and its not changing.

Actaul filimaernt use at the time of the last poll:Filament Usage: 22419.1 mmGranted I'm using the SMT32 port of RRF 3.5.beta4 (and an experimental toolboard) but seems to be the same or simular issue as the OP:

fly_super8_pro_h723 stm32h723-wifi 3.5.0-beta.4_101 Duet 3 Expansion FlySB2040v1_0 FlySB2040v1_0 3.5.0-beta.4_101 Duet WiFi Server n/a 1.27-02S32-D Duet Web Control DWC 3.5.0-beta.4 -

NVM my issue seems to be spacific to the experimental nature of the hardware in that printer. I tested with another printer using current supported toolboars and it worked fine. Will test again when I can get a supported toolboard installed.

-

@dc42 Any news on this? I saw lots of changes on github, but not much being mentioned in the changelog of 3.5rc1.

I updated to rc1 just a few minutes ago and it seems like currently it's a regression compared to 3.5b4.

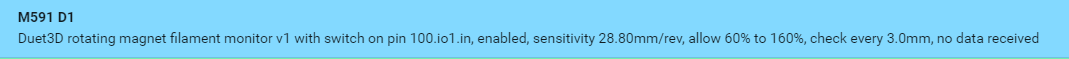

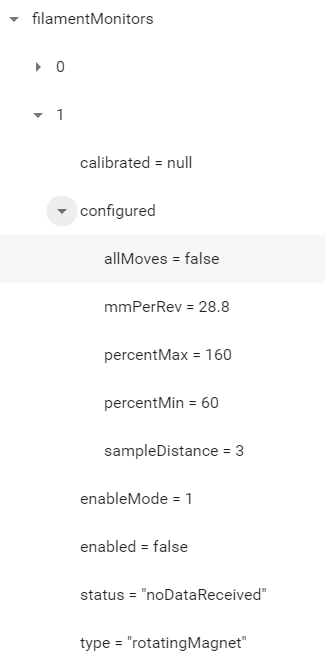

Looks like my sensors are now completely useless, RRF does not even recognize them anymore, meaning that also the runout switch doesn't work anymore (which did work fine on 3.5.b4)The status is now noDataReceived all the time...

M591 D0 Duet3D rotating magnet filament monitor v1 with switch on pin 100.io0.in, disabled, sensitivity 28.80mm/rev, allow 60% to 160%, check every 3.0mm, no data receivedPlease also note that it now says v1? Used to say v4. I guess that's because it doesn't seem to communicate at all with them anymore?

All my 4 sensors show exactly the same.

Hardware- and software setup is exactly the same as in the posts above except for upgrading to 3.5rc1

-

@Diamondback we didn't have time to reproduce this one prior to the RC1 release, so it may still be an issue in RC1. It's still on our list to look at.

-

@dc42 Ok, please let me know if I can assist you in any way, I'd really like to see these monitors working completely for me for the first time

-

@Diamondback please can you try the firmware build at https://www.dropbox.com/scl/fo/tjznycpk7bv7sj71p0ssl/h?rlkey=096p4nvgmigyrb20jj8olg3wu&dl=0 and see whether this issue is still present. There are partial release notes at https://github.com/Duet3D/RepRapFirmware/wiki/Changelog-RRF-3.x-RC#reprapfirmware-350-rc2-changes-since-350-rc1---in-preparation. The filament monitor code has changed significantly since rc1.

-

@dc42 Looks like the issue is the same as with rc1. I do not seem to get any communication with my sensors. The sensors themself appear to be booting up correctly (3x green flash) then they continue to flash alternating green and red. When i insert filament the green LED starts to flash rapidly to the point where it's always lit.

Some data bits:

-

For comparision the same sensor and settings on beta 4 (recorded minutes ago), which at least does communicate with it to some degree, the switch signal works perfectly fine.

Without filament in it:

With filament in it:

-

undefined zendesigner referenced this topic

undefined zendesigner referenced this topic

-

@dc42 Good news

With 3.5rc2, all my sensors appear to work for now

With 3.5rc2, all my sensors appear to work for now  They collect data that seems right, they change status when inserting filament etc.

They collect data that seems right, they change status when inserting filament etc.

I haven't tested yet what happens if they actually detect an issue, but so far so good. Will keep you posted if anything weird comes up. Many thanks

-

undefined T3P3Tony has marked this topic as solved

undefined T3P3Tony has marked this topic as solved