Controle nema 23 brake

-

@Amagatth No, you need a separate 24V supply. PWM (Pulse Width Modulation) does not vary voltage; it just pulses 48V. It will burn out your brake solenoid, or will make your brake turn on and off all the time.

Ian

-

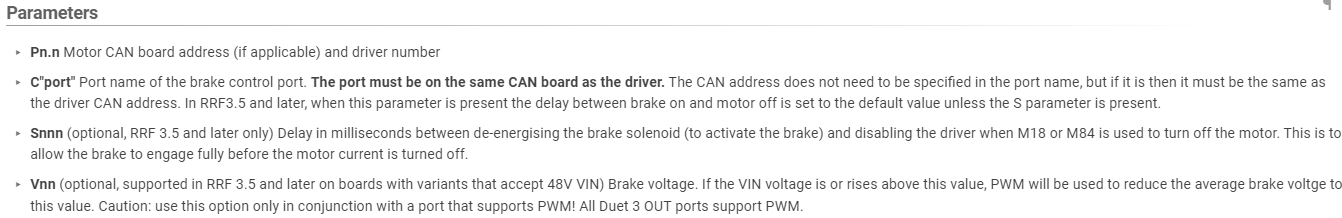

chek V parameter

-

@Amagatth The key word in the V parameter description is average. The V parameter uses PWM to average brake voltage. It will still be 48V, but pulsed so that half the time it is on, and half off. This isn't the same thing as actually reducing the voltage to 24V. You need to check that the brake solenoid can handle this, rather than requiring 24V.

Ian

-

@Amagatth ok so i think i go put a 24 v psu with a relay its faster haha

-

Hi , i set up my brake but i have a pb, when i make a m17 my relay go on i have 24V for my brake , but when i make m18 24v stay on , anyone have a solution plz ?

-

@Amagatth Are you using M569.7 to define the brake? Are both the brake and motor driver connected to the same Duet board? Post your config.g and version of RRF you are using. Also check your config.g is working correctly by sending

M98 P"config.g"Ian

-

@droftarts attached my config. G i have 4 Z motor with all brake connect to out 9 m98p'config.g" work fine and i run on 3.5.2 on the 2 board config.g

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.10 on Mon Dec 21 2020 14:00:11 GMT+0100 (heure normale d’Europe centrale) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Indus-XL" ; set printer name ; Drive M569 P0.0 S1 ; Driver 0.0 marche avant X M569 P0.1 S0 ; Driver 0.1 marche avant Y M569 P0.2 S1 ; Driver 0.2 marche avant Z1 M569 P0.3 S1 ; Driver 0.3 marche avant Z2 M569 P0.4 S1 ; Driver 0.4 marche avant E1 M569 P0.5 S1 M569 P1.0 S0 ; Driver 1.0 marche avant Z3 M569 P1.1 S0 ; Driver 1.1 marche avant Z4 M584 X1.0 Y0.0:0.1 Z0.2:0.3:0.4:0.5 E1.1 ; Assignation moteur Z0.0:0.1:0.2:0.3 M350 X32 Y32 Z32 E32 I1 ; Configuration micro pas M92 X67.425 Y67.65 Z1264.048 E842 ; Configuration step/mm M566 X20.00 Y20.00 Z20 E3320.00 ; Configuration changement de vitesse (mm/min) M203 X8000.00 Y8000.00 Z200 E2200.00 ; Configuration vitesse max (mm/min) M201 X200.00 Y100.00 Z20 E2550.00: ; Configuration acceleration (mm/s^2) M906 X4000 Y4000 Z4200 E650 ; Configuration amperage moteur (mA) ; Mise en repos ; Axis Limits M208 X0 Y0 Z0 S1 ; Coordonnées Mini M208 X2450 Y1600 Z1500 S0 ; Coordonnées Max ; Endstops M574 X2 S1 P"io3.in" ; configure active-high endstop for high end on X via pin io0.in M574 Y2 S1 P"io4.in+io5.in" ; configure active-high endstop for low end on Y via pin io1.in M574 Z1 S2 ; Configuration Z probe ;M591 D0 P1 C"1.io3.in" S1 ; Capteur de fin de filament Tête 1 Pin io2 M591 D0 P7 C"1.io3.in" L6.72 R65:150 E8 S1 ; Z-Probe M950 S0 C" io7.out" ; Creation Pin servo Bltouch M558 P9 C"io7.in" H30 F350 T25000 A1 S0.03 B1 ; Définition Z probe pour bltouch et la hauteur/ vitesse de probe G31 P500 X+52.2 Y-25.47 Z1.29 ; Définition Z probe Offset ;M557 X10:2950 Y25:630 S200:150 ; Définition Grille de palpage M557 X10:2450 Y25:630 S100:75 ; Définition Grille de palpage ; Sensor M308 S1 P"spi.cs0" Y"rtd-max31865" W2 A"Tete-H" ; Sensor 1 (tête) en pt 100 M308 S2 P"spi.cs1" Y"rtd-max31865" W2 A"Tete-M" ; Sensor 1 (tête) en pt 100 ;M308 S3 P"spi.cs3" Y"rtd-max31865" W2 A"Tete-B" ; Sensor 1 (tête) en pt 100 M308 S0 P"temp0" Y"pt1000" R2200 A"Lit0" ; Sensor 0 en PT 1000 M308 S4 P"temp1" Y"pt1000" R2200 A"Lit1" ; Sensor 2 en PT 1000 M308 S5 P"1.temp0" Y"pt1000" R2200 A"Lit2" ; Sensor 3 en PT 1000 M308 S6 P"1.temp1" Y"pt1000" R2200 A"Lit3" ; Sensor 4 en PT 1000 ; Chauffe M950 H1 C"out1" T1 Q10 ; Tête assigné a sensor 1 M950 H2 C"out2" T2 Q10 ; Tête assigné a sensor 1 ;M950 H3 C"io2.out" T3 Q10 ; Tête assigné a sensor 1 M950 H0 C"out7" T0 Q10 ; Lit 0 assigné a sensor 0 M950 H4 C"out8" T4 Q10 ; Lit 1 assigné a sensor 2 M950 H5 C"1.out6" T5 Q10 ; Lit 3 assigné a sensor 3 M950 H6 C"1.out0" T6 Q10 ; Lit 4 assigné a sensor 4 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M307 H4 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M307 H5 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M307 H6 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M307 H2 B0 S1.00 ;M307 H3 B0 S1.00 M307 H0 R0.324 C216.0 D7.83 S1.00 V25.0 ; PID Lit 0 M307 H4 R0.324 C216.0 D7.83 S1.00 V25.0 ; PID Lit 1 M307 H5 R0.324 C216.0 D7.83 S1.00 V25.0 ; PID Lit 2 M307 H6 R0.324 C216.0 D7.83 S1.00 V25.0 ; PID Lit 3 M307 H1 R0 C0 D0 S0.7 V0 ; PID Tête M307 H2 R0 C0 D0 S0.7 V0 ; PID Tête ;M307 H3 R0 C0 D0 S0.70 V0 ; PID Tête M143 H0 S100 ; set temperature limit for heater 0 to 100C M143 H4 S100 ; set temperature limit for heater 2 to 100C M143 H5 S100 ; set temperature limit for heater 3 to 100C M143 H6 S100 ; set temperature limit for heater 4 to 100C M143 H1 S400 ; set temperature limit for heater 1 to 500C M143 H2 S400 ; set temperature limit for heater 1 to 500C ;M143 H3 S400 ; set temperature limit for heater 1 to 500C M140 P0 H0 ; Map Des Bed M140 P1 H4 ; Map Des Bed M140 P2 H5 ; Map Des Bed M140 P3 H6 ; Map Des Bed ; Fans M950 F1 C"1.out7" Q500 C"Ventil Piece" ; Ventillateur tête 1 sur pin out7 M106 P1 h-1 ; Ventillateur 1 en thermostatique demarrage 45 degrés M569.7 P0.2 C"0.out9" s20 ; Tools M563 P0 D0 H1:2:3 F1 S"Tete" ; La tête 1 utilise l'extrudeur 1 et le ventillateur 3 G10 P0 X0 Y0 Z0 ; definition offset tête 1 G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ;M563 P2 D1 H2 F4 ; La tête 2 utilise l'extrudeur 2 et le ventillateur 4 ;G10 P2 X0 Y0 Z0 ; definition offset tête 2 ;G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C ;Correction des vis M669 1.00 0 0 0 1.00 0 0 0 1.00 M671 X-185.0:-185.0:2660:2660 Y0.0:660:0:660 S40 P5 ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss M572 D0 S0.03 ; Gestion du pressure advance m280 p0 s160 ;M591 D0 P1 C"io2.in" S1 T0 M501 m500 -

@droftarts Hey

how are you ? you see anything wrong ?

how are you ? you see anything wrong ? -

@Amagatth If the brakes are still not working correctly, can you show how you have wired the brake relays? The out9 pin is on the GND side (all switching MOSFETs are on the GND side, after the load), so you need to supply 24V to the positive side of the brake relay (you said you were going to get a 24V PSU for the brake) and connect from the negative side of the relay to out9 pin (not the VOUTLC2 pin on the OUT 9 connector, this is just the input voltage, which I think is 48V?).

I don't think you need the CAN address of the pin in the M569.7 command, so try changing that to:

M569.7 P0.2 C"out9" S20Some changes for your config.g to avoid errors:

Comment out this:M669 1.00 0 0 0 1.00 0 0 0 1.00Remove this from the end of config.g, you don't want to load config-override.g then immediately save it again:

m500Ian

-

@droftarts i change my 24 V now the board is on 24V ( 48V before) so i can direct command brake with out 9 in 24V

and i delet the line no pb

-

@Amagatth Brake PWM is implemented on the EXP1HCL and on the M23CL. I have used PWM to run a 24V brake with 48V supply. It appears to work properly although the brake makes a slight hum at the PWM frequency.

Which board are you using to drive the motor and brake?

-

undefined droftarts referenced this topic

undefined droftarts referenced this topic

-

@dc42 Its ok i put my card in 24 V i use a duet 3 6hc + 3hc with brake on duet 6hc and motor on 6hc

-

@Amagatth And the brake is working now?

Edit:

I've updated the M569.7 entry to say:Vnn (optional, supported in RRF 3.5 and later on EXP1HCL and M23CL that accept 48V VIN) Brake voltage.

And added a second example:

M569.7 P0.2 C"out9" S20 ; driver 2 on mainboard uses port out9 to control the brake, with 20ms delay

Ian

-

@droftarts no if i make a m18 moto are disable but dont active 24 v for brake

-

@Amagatth okay, @dc42 has it on his list to fix. See https://github.com/Duet3D/RepRapFirmware/issues/1023

Ian

-

@droftarts if i understand this post he say effect is on duet 3 expansion board ... i have my motor on the duet 3 6hc

-

@Amagatth he added code to enable PWM on 1HCL and M23CL. From what I understand, the code has broken turning off motor and enabling brake on other boards, like your 6HC, and the 6XD. But I see from the other thread there is a temporary fix from @timschneider that works for you.

Ian

-

@droftarts i apply the new .bin file and it work perfectly !

-

I have now implemented a fix (the same as Tim's fix) for this issue in the 3.5-dev and 3.6-dev source code, so it will be included in the next builds. I can provide temporary 3.5.2+1 builds if anyone needs them.