Poor overhang performance

-

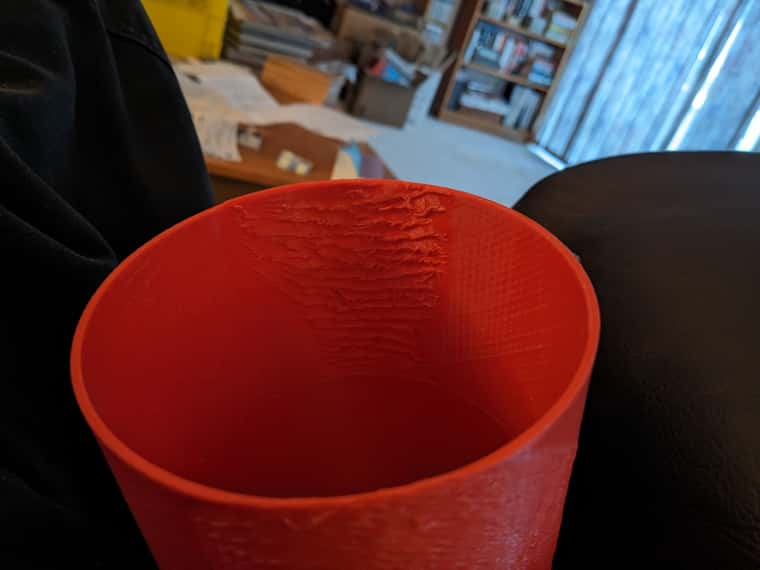

I am trying to print a 4 inch sch 40 45 degree pipe fitting. The fitting is printed with one open end flat on the build plate. Since this is a 45 degree fitting, I was under the impression that the most overhang I would encounter would be 45 degrees. Well this seems to not be correct for some reason or other that I don't really understand. I get severe artifacts on what I would think are the highest overhang portions.

I test-printed an overhang test piece with the chosen settings using PrusaSlicer and there was no distortion on the highest angled overhang which was 70 degrees (PS automatically reduces speed and turns the part cooling fan to 100%)

I also tried slicing the part with different settings of maximum overhang to see where PS started inserting supports and that happened at 75 degrees approximately.

I have a number of questions:

Since this fitting is a 45 degree fitting of a 4" pipe, are there actual sections where the overhang is more than 45 degrees?

Is there any other way that I can print this part without using a huge amount of support material? I tried different print orientations but that didn't get me that far.

Attached are a couple of photos of the artifact which to me look like a case of not enough cooling (I printed at 205C with PLA) but printing the overhang calibration print showed no difference between 205C and 195C.

-

@jens55 Looks to me like there is a directional problem with the part cooling. If so then you should be able to rotate the part in the slicer and have the blobbiness move to a different place on the print but stay where it is relative to the printer.

If it's just generally inadequate part cooling then slowing the print down will probably help as it gives more cooling time relative to extrusion.

-

@MJLew, thanks for the input. I have rotated the print and reduced the speed from 180 t0 100 mm/sec and started another print. It is a 6 hr print so it will be a while before I can see if there is a difference.

In retrospect, while PS does indeed slow down for bridges, I am not entirely sure this applies to overhangs in this part. Looking at the speed as reported by PS, it seems there was no slowdown. On the other hand, the overhang test sample did show a drastic speed reduction for the very outside filament laid down. It should be interesting to see how this next print turns out. -

@MJLew, thanks again for your suggestions. This morning I collected the new print and there was only a tiny area that showed the same symptoms as the earlier print. It was a thing of (mostly) beauty!

I do not know what parameter change(s) caused the huge improvement. I forgot to mention that I had also added a tiny bit of support but that support was not in the problem areas but rather what PS felt strongly about.

I need one more of these fittings so I will get to reverse one or two of the previous changes to maybe narrow things down a bit more but my gut feeling is that reducing the speed was the cause of the improvement.

The next print will be started tonight for another overnight print.