My Second build (in progress)

-

Well ive decided to start slowly build another printer from my new design in this thread : https://forum.duet3d.com/topic/35942/to-build-another-printer-or-not/5?_=1722808557537

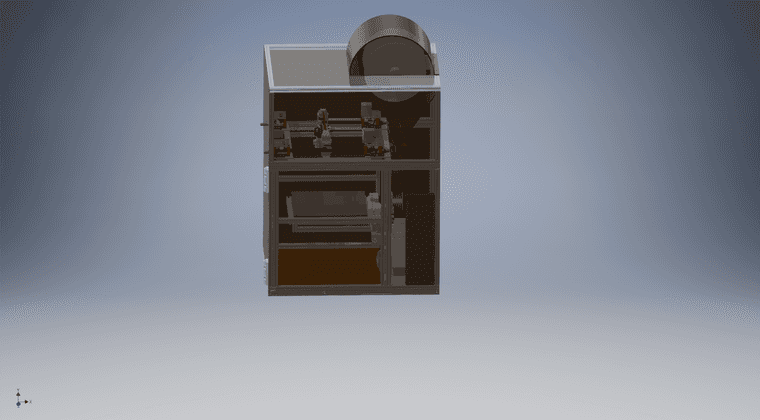

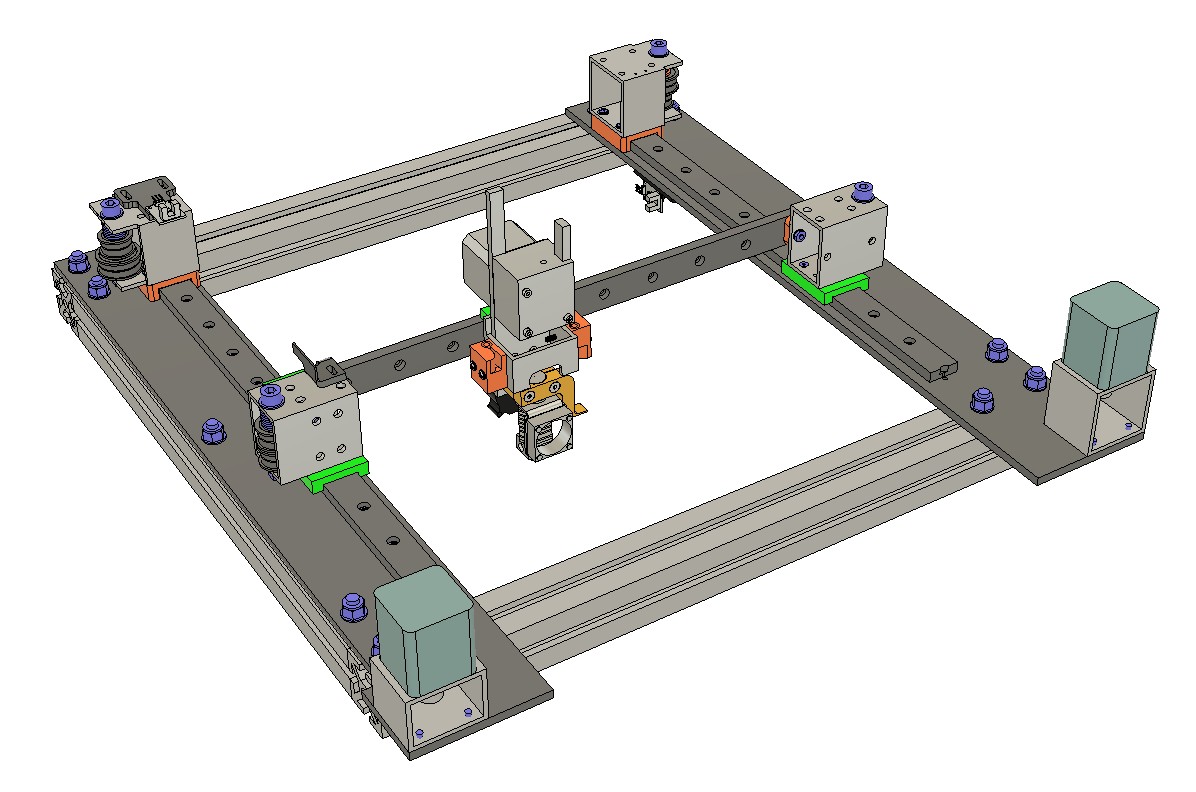

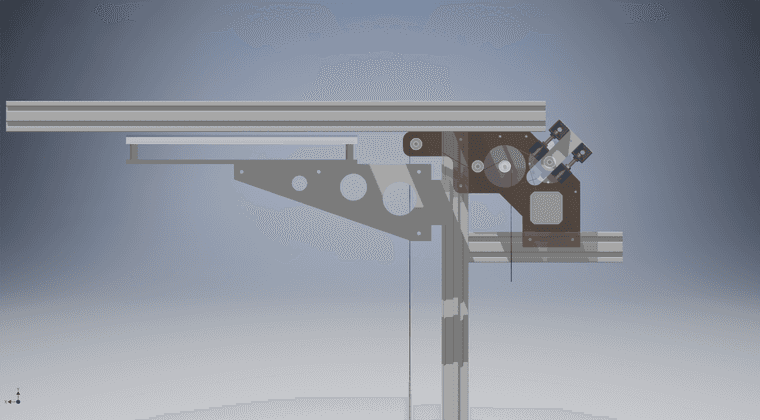

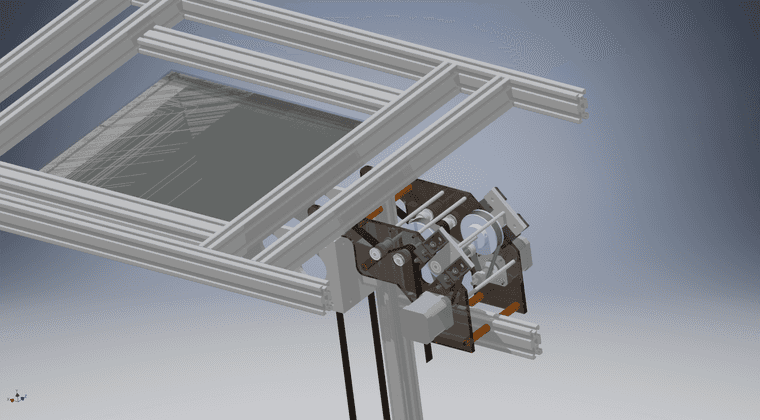

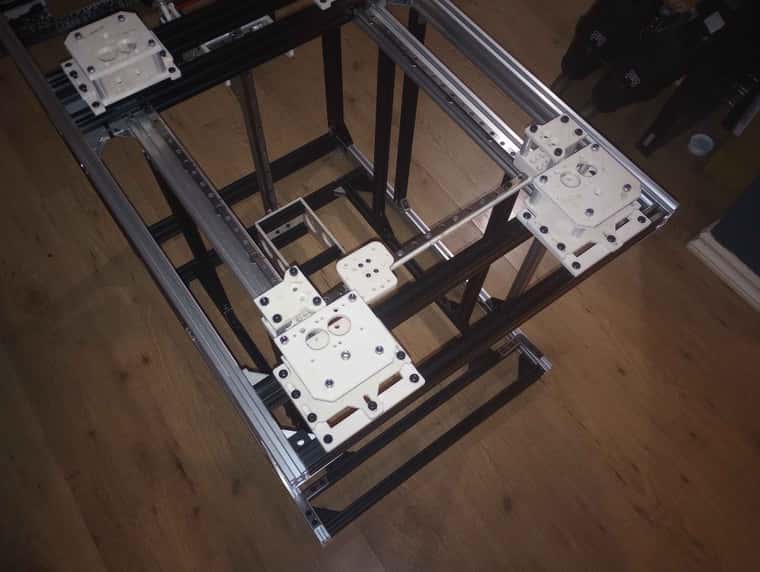

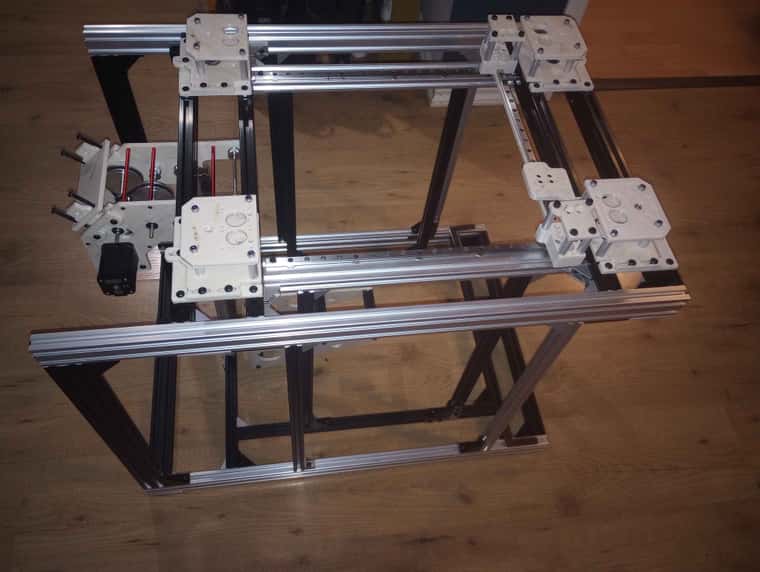

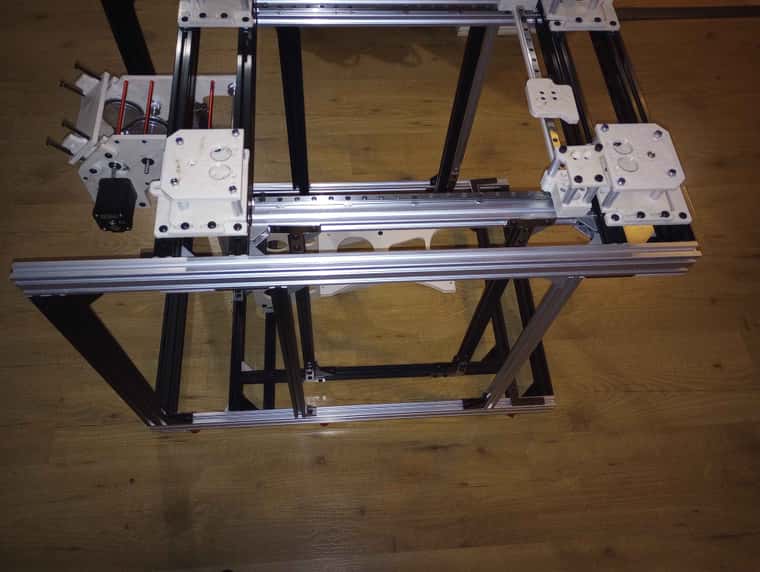

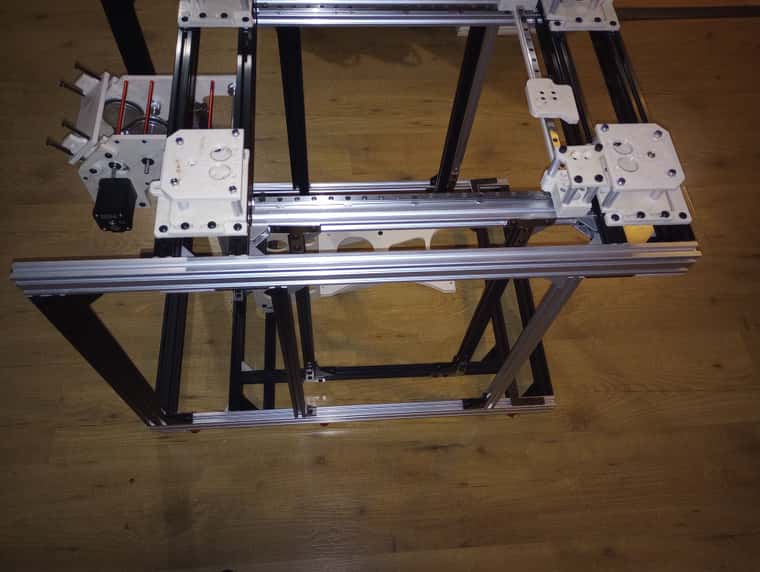

to fix some of the shortcoming from my actual printer , since i really want to print poly carbonate so smaller build area about 250x250mmx250 mm , it will include a heated chamber and a water cooled hotend , my motor mount are designed for an AWD setup as well or 6WD . all in a 500x750x 800mm total dimension . Most important part is it will be a 48V system

Trying to keep designing my part as simple as possible so that once testing and build is done part can be cut out of aluminum plate via waterjet cutting since it is a cheap .

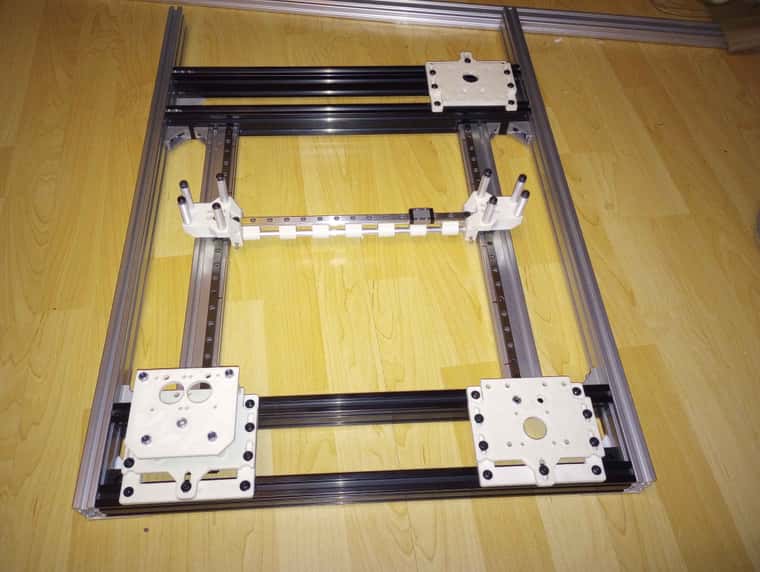

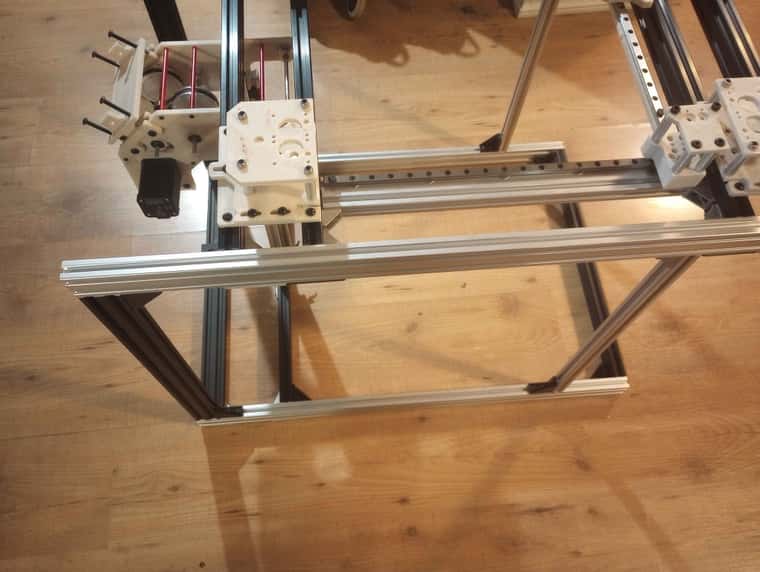

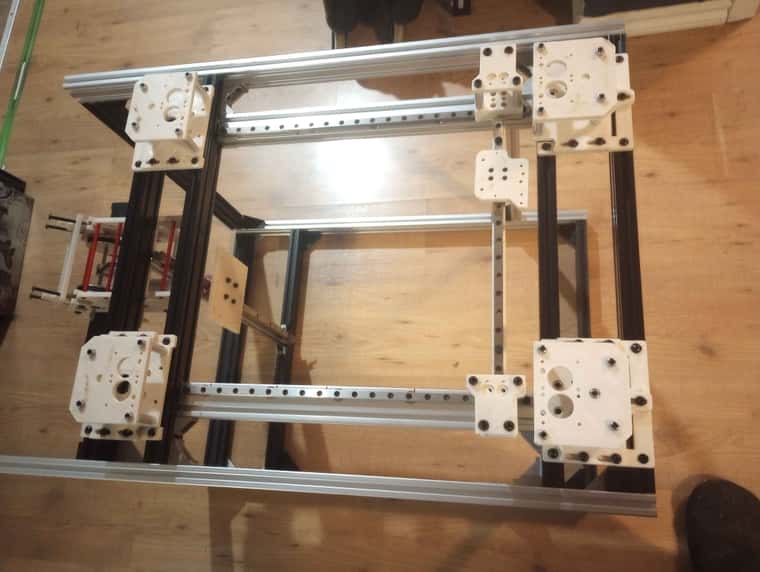

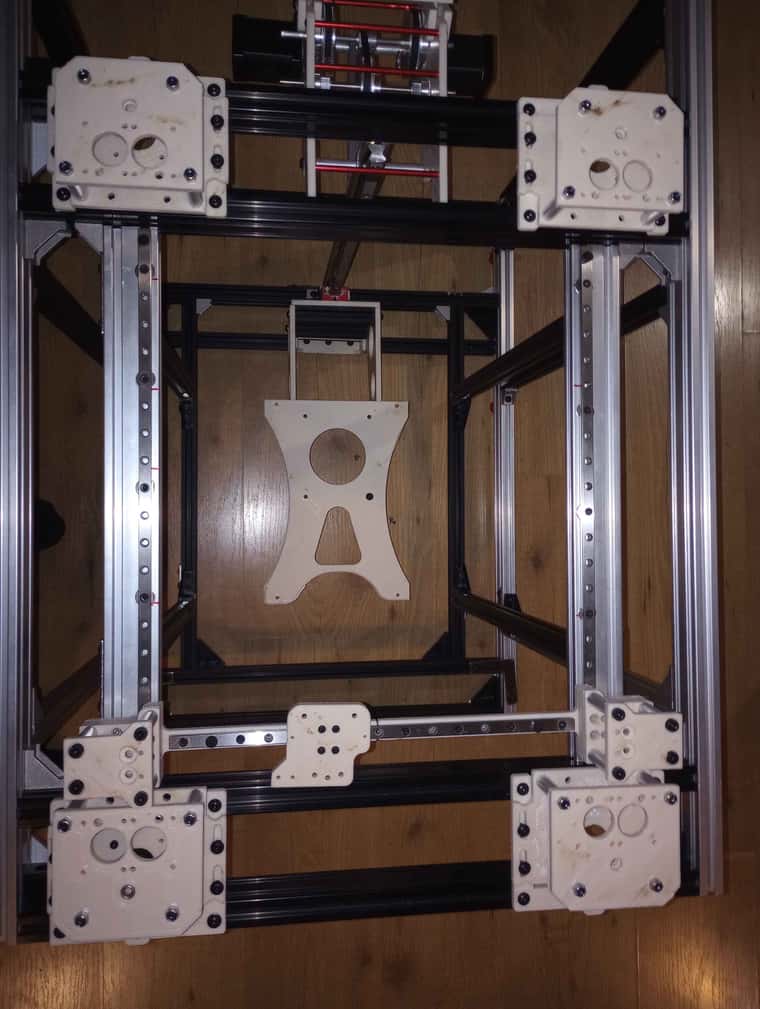

here the important part the top frame that will hold linear rail and support everything . just need to fully square it and this should not move much overtime , like regular Cube frame that most printer are base of ,

-

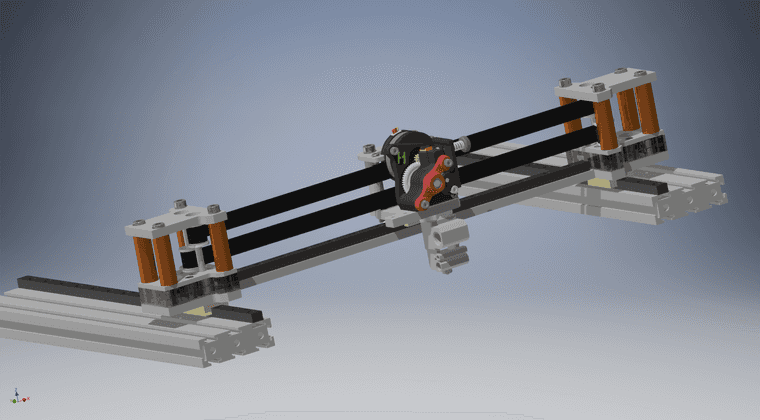

Well already have some change planned in my design for the x gantry , will redesign a few things so they can use aluminum plate and be waterjet cut only . To reduce cost to a maximum on final machine .

-

-

-

-

@Dad003 You can simplify construction and probably reduce mass by using rectangular aluminum tubing to make the two pulley blocks at the ends of the axis. You can use it for motor mounts, too.

If you bolt the t-slot pieces directly to each other you won't need all those corner braces. Tap the ends of the inside t-slot pieces, and drill tool-access holes at appropriate locations in the outside t-slot pieces. You can use button head cap screws with washers in the slots to connect two pieces together. This assumes that the ends of the pieces are cut/milled square. See: https://www.youtube.com/watch?v=HfcXjYWw5UQ

-

@mrehorstdmd said in My Second build (in progress):

@Dad003 You can simplify construction and probably reduce mass by using rectangular aluminum tubing to make the two pulley blocks at the ends of the axis. You can use it for motor mounts, too.

If you bolt the t-slot pieces directly to each other you won't need all those corner braces. Tap the ends of the inside t-slot pieces, and drill tool-access holes at appropriate locations in the outside t-slot pieces. You can use button head cap screws with washers in the slots to connect two pieces together. This assumes that the ends of the pieces are cut/milled square. See: https://www.youtube.com/watch?v=HfcXjYWw5UQ

ill take that in consideration , but my plan here is to have everything out of aluminum plate , water jet cut since i dont have the equipment to do a lot of drilling or machining , the machine i would need for that at work never has the right setup on it lol , with that process i can easily had a lots of cut to lighten everything since it all on mgn9c block , him still at early design anyway just slowly designing and then printing things and see how it look like , knowing myself i will most likely fill up a whole box of parts again until final design .

still not sure about what kind of probe i will use becasue of the heated chamber been thinking of a klicky probe since there are high temp switch

-

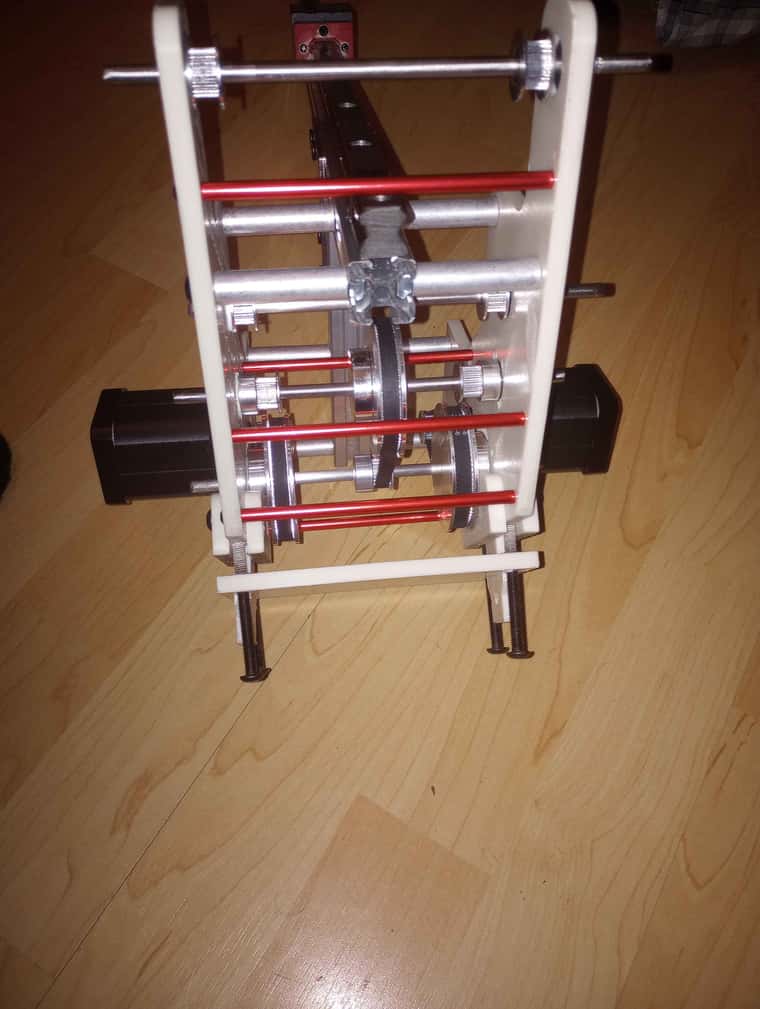

Slowly simplifying every component as well, working in my z axis system with belt , current printer use 20>60-20>60-20 this for 1380 step , this one will use 20>80-20>80-20 for over 2500 step with a .9 stepper motor , and the holding torq is.so good that with no power bed doesn't fall down .

-

-

@Dad003 One of these will make your life much easier. The 30:1 reduction enables it to lift very heavy beds, and it doesn't move when the motor is disabled, allowing restart of prints in the event of a power failure. It doesn't require brakes, additional wiring, or additional configuration. Just treat the motor like a normal stepper. I used 60 tooth pulleys on the shaft to get 20 um per full step from the motor. I've been using it for my 695 mm Z-axis about 7 years without any problems. The gear quality is very high, so there are no gear induced artifacts in the z-axis of prints.

-

@mrehorstdmd said in My Second build (in progress):

@Dad003 One of these will make your life much easier. The 30:1 reduction enables it to lift very heavy beds, and it doesn't move when the motor is disabled, allowing restart of prints in the event of a power failure. It doesn't require brakes, additional wiring, or additional configuration. Just treat the motor like a normal stepper. I used 60 tooth pulleys on the shaft to get 20 um per full step from the motor. I've been using it for my 695 mm Z-axis about 7 years without any problems. The gear quality is very high, so there are no gear induced artifacts in the z-axis of prints.

Do you have a link to this particular one ?

My pulley system doesn't drop the bed either , I've tested it and you need over 10 pound on the table to even make it move

-

@Dad003 click on "one of these" in the post above. That guy has been selling the things via ebay for many years.

Your design may work, but look at all the parts and space required. The worm gear box with attached motor is as simple as it gets. -

@mrehorstdmd yea i understand that , but still after looking at that price , most of my component are readily available on amazon , other than the 2 side plates that need to be water jet cut for the final version it cost a fraction of that worm gear setup .

-

@Dad003 I thought you were trying to simplify the design. Never mind.

-

@mrehorstdmd kinda but I want to keep cost down as well . From my early calcul this will be an expansive build about 3000 to 5000 $ at least . Depending of material to enclose the full printer.

-

This post is deleted! -

-

-

-