temperature not working

-

I'm using the duet 3 6hc and the temperature does not increase.

When I do the PID autotune it works without any problems, but when I chose the tool to feed the fillament it appears to never complete the tool change and there for it doesn't heat the nozzle so the only reason I know that the heat is woking it's because of PID autotune.Here it's my config:

code_tex ; Configuration file for RepRapFirmware on Duet 3 Main Board 6HC ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.8 on Sat Jan 04 2025 14:31:40 GMT+0000 (Hora padrão da Europa Ocidental) ; General G90 ; absolute coordinates M83 ; relative extruder moves M550 P"Board Printer" ; set hostname ; Accessories M575 P1 S0 B57600 ; configure PanelDue support ; Network M552 P0.0.0.0 S1 ; configure Ethernet adapter M586 P0 S1 ; configure HTTP ; Wait a moment for the CAN expansion boards to become available G4 S2 ; Smart Drivers M569 P0.0 S1 D2 ; driver 0.0 goes forwards (Z axis) M569 P0.1 S1 D2 ; driver 0.1 goes forwards (Z axis) M569 P0.2 S1 D2 ; driver 0.2 goes forwards (Z axis) M569 P0.3 S1 D2 ; driver 0.3 goes forwards (Z axis) M569 P0.4 S1 D2 ; driver 0.4 goes forwards (extruder 1) M569 P0.5 S1 D2 ; driver 0.5 goes forwards (extruder 0) M569 P1.2 S1 D2 ; driver 1.2 goes forwards (X axis) M569 P1.3 S0 D2 ; driver 1.3 goes backwards (U axis) M569 P1.4 S1 D2 ; driver 1.4 goes forwards (Y axis) M569 P1.5 S0 D2 ; driver 1.5 goes backwards (V axis) ; Motor Idle Current Reduction M906 I30 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; Axes M584 X1.2 Y1.4 Z0.0:0.1:0.2:0.3 U1.3 V1.5 ; set axis mapping M350 X16 Y16 Z16 U16 V16 I1 ; configure microstepping with interpolation M906 X1500 Y2300 Z2300 U1500 V2300 ; set axis driver currents M92 X79.60199 Y51.282051 Z400 U79.60199 V51.282051 ; configure steps per mm M208 X0:200 Y0:2300 Z0:344.5 U0:200 V0:2300 ; set minimum and maximum axis limits M566 X900 Y600 Z12 U900 V600 ; set maximum instantaneous speed changes (mm/min) M203 X6000 Y4800 Z600 U6000 V4800 ; set maximum speeds (mm/min) M201 X500 Y80 Z20 U500 V80 ; set accelerations (mm/s^2) ; Extruders M584 E0.5:0.4 ; set extruder mapping M350 E16:16 I1 ; configure microstepping with interpolation M906 E1000:1000 ; set extruder driver currents M92 E420:420 ; configure steps per mm M566 E120:120 ; set maximum instantaneous speed changes (mm/min) M203 E3600:3600 ; set maximum speeds (mm/min) M201 E250:250 ; set accelerations (mm/s^2) ; Kinematics M669 K0 ; configure Cartesian kinematics ; Endstops M574 X1 P"1.io0.in" S1 ; configure X axis endstop M574 Y1 P"1.io5.in" S1 ; configure Y axis endstop M574 Z2 P"1.io1.in+1.io2.in+1.io3.in+1.io4.in" S1 ; configure Z axis endstop M574 U1 P"1.io6.in" S1 ; configure U axis endstop M574 V1 P"io1.in" S1 ; configure V axis endstop ; Sensors M308 S0 P"temp1" Y"thermistor" A"X Temp" T100000 B4388 C7.06e-8 ; configure sensor #0 M308 S1 P"temp0" Y"thermistor" A"U Temp" T100000 B4388 C7.06e-8 ; configure sensor #1 ; Heaters M950 H1 C"out1" T0 ; create heater #1 M143 H1 P0 T0 C0 S290 A3 ; configure heater monitor #0 for heater #1 M307 H1 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1 M301 H1 P0 I0 D0 ; apply custom PID parameters for heater #1 M950 H2 C"out2" T1 ; create heater #2 M143 H2 P0 T1 C0 S290 A3 ; configure heater monitor #0 for heater #2 M307 H2 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #2 M301 H2 P0 I0 D0 ; apply custom PID parameters for heater #2 ; Fans M950 F0 C"out3" ; create fan #0 M106 P0 S0 L0 X1 B0.1 ; configure fan #0 M950 F1 C"out4" ; create fan #1 M106 P1 S0 L0 X1 B0.1 ; configure fan #1 ; Tools M563 P0 S"Mirror Mode" D0:1 H1:2 F0:1 L1 ; create tool #0 M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C M567 P0 ; set mixing ratios for tool #0 M563 P1 S"Copy Mode" D0:1 H1:2 F0:1 L1 ; create tool #1 M568 P1 R0 S0 ; set initial tool #1 active and standby temperatures to 0C M567 P1 ; set mixing ratios for tool #1 M563 P2 S"X Stand Alone Mode" D0 H1 F0 ; create tool #2 M568 P2 R0 S0 ; set initial tool #2 active and standby temperatures to 0C M563 P3 S"Y Stand Alone Mode" D1 H2 F1 ; create tool #3 M568 P3 R0 S0 ; set initial tool #3 active and standby temperatures to 0C ; Miscellaneous M501 ; load saved parameters from non-volatile memory T0 ; select first tool -

@HugoZM can you post your tool change files for each tool too

-

@jay_s_uk I don't have anything on them, I dont know how they work.

I'm new to all of this -

How are you choosing the tool?

-

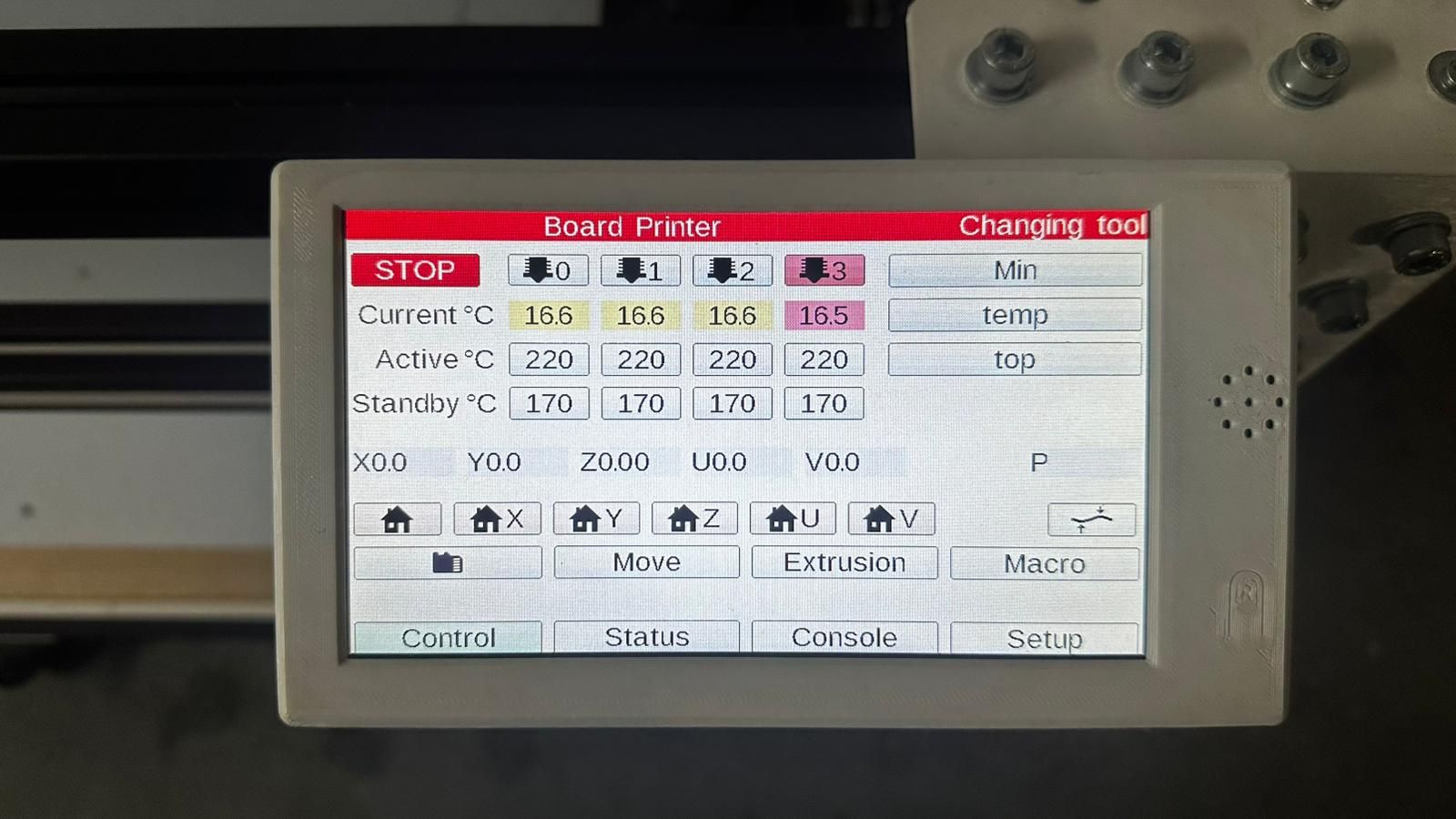

@HugoZM just selecting it on my panel due and then on the upper right corner it says changing tool but then nothing more happens and temp stays the same

-

Please send M122 and M98 P"config.g" in the gcode console and report the results.

-

@Phaedrux `M122

code_text `` === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.5.1 (2024-04-19 14:30:55) running on Duet 3 MB6HC v1.02 or later (standalone mode) Board ID: 08DJM-9P63L-DJ3T0-6J1DG-3SJ6T-1B3HB Used output buffers: 5 of 40 (29 max) === RTOS === Static ram: 155208 Dynamic ram: 123480 of which 0 recycled Never used RAM 67304, free system stack 204 words Tasks: NETWORK(1,ready,37.2%,183) ETHERNET(5,nWait 7,0.2%,317) HEAT(3,nWait 6,0.0%,325) Move(4,nWait 6,0.0%,336) CanReceiv(6,nWait 1,0.0%,797) CanSender(5,nWait 7,0.0%,334) CanClock(7,delaying,0.0%,348) TMC(4,nWait 6,9.3%,56) MAIN(1,running,53.1%,105) IDLE(0,ready,0.2%,30), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:01:19 ago, cause: power up Last software reset at 2025-01-03 17:25, reason: User, Gcodes spinning, available RAM 69368, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 MCU temperature: min 13.1, current 24.1, max 24.1 Supply voltage: min 24.0, current 24.1, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.2, max 12.4, under voltage events: 0 Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min n/a, mspos 8, reads 43649, writes 16 timeouts 0 Driver 1: standstill, SG min n/a, mspos 8, reads 43649, writes 16 timeouts 0 Driver 2: standstill, SG min n/a, mspos 8, reads 43649, writes 16 timeouts 0 Driver 3: standstill, SG min n/a, mspos 8, reads 43649, writes 16 timeouts 0 Driver 4: standstill, SG min n/a, mspos 8, reads 43649, writes 16 timeouts 0 Driver 5: standstill, SG min n/a, mspos 8, reads 43650, writes 16 timeouts 0 Date/time: 2025-01-04 20:14:49 Slowest loop: 5.06ms; fastest: 0.07ms === Storage === Free file entries: 20 SD card 0 detected, interface speed: 25.0MBytes/sec SD card longest read time 5.3ms, write time 0.0ms, max retries 0 === Move === DMs created 125, segments created 0, maxWait 0ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0 === DDARing 0 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Movement locks held by null, null HTTP is ready with "M122" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0000000 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === CAN === Messages queued 725, received 654, lost 0, errs 49, boc 0 Longest wait 1ms for reply type 6018, peak Tx sync delay 7908, free buffers 50 (min 49), ts 398/397/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 5.93ms; fastest: 0.03ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 = Ethernet = Interface state: active Error counts: 0 0 0 1 0 0 Socket states: 5 5 2 2 2 0 0 0 === WiFi === Interface state: disabled Module is disabled Failed messages: pending 0, notrdy 0, noresp 0 Socket states: 0 0 0 0 0 0 0 0 === Multicast handler === Responder is inactive, messages received 0, responses 0code_text M98 P"config.g"

Tool 0 mix ratios: 1.000:0.000 Tool 1 mix ratios: 1.000:0.000 M98 P"config.g" HTTP is enabled on port 80 -

@HugoZM Can you please post your config_override.g so that we can see which PID parameters are applied to the heaters?

When @jay_s_uk asked for your tool change files, you stated that you "don't have anything on them". Does that mean there are no tfreeN.g, tpreN.g or tpostN.g files in your /sys/ directory (N being the respective tool number) at all?

-

@infiniteloop

The (tfreeN.g, tpreN.g or tpostN.g ) files are on the directory but I don't know what to write on them, I will put the example fo T0

tfree0.g tpost0.g tpre0.g; Heaters M950 H1 C"out1" T0 ; create heater #1 M143 H1 P0 T0 C0 S290 A3 ; configure heater monitor #0 for heater #1 M307 H1 R2.918 K0.326:0.000 D7.22 E1.35 S1.00 B0 V24.0 ; configure model of heater #1 M301 H1 P0 I0 D0 ; apply custom PID parameters for heater #1 M950 H2 C"out2" T1 ; create heater #2 M143 H2 P0 T1 C0 S290 A3 ; configure heater monitor #0 for heater #2 M307 H2 R3.069 K2.527:0.000 D6.39 E1.35 S1.00 B0 V24.0 ; configure model of heater #2 M301 H2 P0 I0 D0 ; apply custom PID parameters for heater #2 -

@HugoZM Sorry, but you posted the heater portion from your config.g file, NOT the file config_override.g which should contain, among other settings, the results of your PID autotune. This file (config_override.g) is called at the end of config.g with

M501.As I interpret your config, the

M301commands per heater kinda "reset" the tuning, setting all PID parameters to 0. See the GCode Dictionary for details. IMHO, this requires the presence of a config_override.g file.As a side note: I prefer to place (copy/paste) the tuning results into config.g, the necessity of a second "hidden" parameter file obscures the real configuration somehow. But that's a matter of taste.

Thanks for your tool change files (tool 0). tpre0.g and tfree0.g are empty, tpost0.g just waits until the temperature of tool 0 is reached. If the same scheme applies to tool 3, that's where it waits forever and a second when you select T3 from the PanelDue - given that, for some reason, your tuning parameters have no effect.

-

@HugoZM said in temperature not working:

Duet 3 MB6HC version 3.5.1

Can you update your firmware to the latest as well?

Upload this zip file as is to the system tab in DWC.

https://github.com/Duet3D/RepRapFirmware/releases/download/3.5.4/Duet2and3Firmware-3.5.4.zip

-

@infiniteloop I don't have a config_override.g file because like you I prefer to edit directly from the config but I posted the first time I posted one without the updated values.

So I should delete the M301? -

So I should delete the M301?

comment these lines out and see whether you get a temperature rise.

Edit: And remove the

M501command at the very end of the config. -

@infiniteloop Thank you so much its finally woking

Thank you eveyone that helped -

@infiniteloop @jay_s_uk @Phaedrux

Another question, when I home the axis the ethernet stops working -

when I home the axis the ethernet stops working

Interesting. Welcome back

I can’t imagine any firmware reason. I assume it’s either a mechanical or electrical failure. First, we need a lot more details:- Which axis induces the effect?

- Is the connection lost while or after homing?

- Does ethernet reconnect after a while or only after a reboot?

- Is the PanelDue still functional when ethernet is lost?

- Which LEDs on the board are lit or blinking?

Please send M122 after the event and post the report here.

-

- Y axis

- after homing

- doesnt reconect only if rebooted

- yes

- dont know the leds

code_tex ; Configuration file for RepRapFirmware on Duet 3 Main Board 6HC ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.8 on Sat Jan 04 2025 14:31:40 GMT+0000 (Hora padrão da Europa Ocidental) ; General G90 ; absolute coordinates M83 ; relative extruder moves M550 P"Board Printer" ; set hostname ; Accessories M575 P1 S0 B57600 ; configure PanelDue support ; Network M552 P0.0.0.0 S1 ; configure Ethernet adapter M586 P0 S1 ; configure HTTP ; Wait a moment for the CAN expansion boards to become available G4 S2 ; Smart Drivers M569 P0.0 S1 D2 ; driver 0.0 goes forwards (Z axis) M569 P0.1 S1 D2 ; driver 0.1 goes forwards (Z axis) M569 P0.2 S1 D2 ; driver 0.2 goes forwards (Z axis) M569 P0.3 S1 D2 ; driver 0.3 goes forwards (Z axis) M569 P0.4 S1 D2 ; driver 0.4 goes forwards (extruder 1) M569 P0.5 S1 D2 ; driver 0.5 goes forwards (extruder 0) M569 P1.2 S1 D2 ; driver 1.2 goes forwards (X axis) M569 P1.3 S0 D2 ; driver 1.3 goes backwards (U axis) M569 P1.4 S1 D2 ; driver 1.4 goes forwards (Y axis) M569 P1.5 S0 D2 ; driver 1.5 goes backwards (V axis) ; Motor Idle Current Reduction M906 I30 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; Axes M584 X1.2 Y1.4 Z0.0:0.1:0.2:0.3 U1.3 V1.5 ; set axis mapping M350 X16 Y16 Z16 U16 V16 I1 ; configure microstepping with interpolation M906 X1500 Y2300 Z2300 U1500 V2300 ; set axis driver currents M92 X79.60199 Y51.282051 Z400 U79.60199 V51.282051 ; configure steps per mm M208 X0:200 Y0:2300 Z0:344.5 U0:200 V0:2300 ; set minimum and maximum axis limits M566 X900 Y600 Z12 U900 V600 ; set maximum instantaneous speed changes (mm/min) M203 X6000 Y4800 Z600 U6000 V4800 ; set maximum speeds (mm/min) M201 X500 Y80 Z20 U500 V80 ; set accelerations (mm/s^2) ; Extruders M584 E0.5:0.4 ; set extruder mapping M350 E16:16 I1 ; configure microstepping with interpolation M906 E1000:1000 ; set extruder driver currents M92 E420:420 ; configure steps per mm M566 E120:120 ; set maximum instantaneous speed changes (mm/min) M203 E3600:3600 ; set maximum speeds (mm/min) M201 E250:250 ; set accelerations (mm/s^2) ; Kinematics M669 K0 ; configure Cartesian kinematics ; Endstops M574 X1 P"1.io0.in" S1 ; configure X axis endstop M574 Y1 P"1.io5.in" S1 ; configure Y axis endstop M574 Z2 P"1.io1.in+1.io2.in+1.io3.in+1.io4.in" S1 ; configure Z axis endstop M574 U1 P"1.io6.in" S1 ; configure U axis endstop M574 V1 P"io1.in" S1 ; configure V axis endstop ; Sensors M308 S0 P"temp1" Y"thermistor" A"X Temp" T100000 B4388 C7.06e-8 ; configure sensor #0 M308 S1 P"temp0" Y"thermistor" A"U Temp" T100000 B4388 C7.06e-8 ; configure sensor #1 ; Heaters M950 H1 C"out1" T0 ; create heater #1 M143 H1 P0 T0 C0 S290 A3 ; configure heater monitor #0 for heater #1 M307 H1 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1 M950 H2 C"out2" T1 ; create heater #2 M143 H2 P0 T1 C0 S290 A3 ; configure heater monitor #0 for heater #2 M307 H2 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #2 ; Fans M950 F0 C"out3" ; create fan #0 M106 P0 S0 L0 X1 B0.1 ; configure fan #0 M950 F1 C"out4" ; create fan #1 M106 P1 S0 L0 X1 B0.1 ; configure fan #1 ; Tools M563 P0 S"Mirror Mode" D0:1 H1:2 F0:1 L1 ; create tool #0 M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C M567 P0 ; set mixing ratios for tool #0 M563 P1 S"Copy Mode" D0:1 H1:2 F0:1 L1 ; create tool #1 M568 P1 R0 S0 ; set initial tool #1 active and standby temperatures to 0C M567 P1 ; set mixing ratios for tool #1 M563 P2 S"X Stand Alone Mode" D0 H1 F0 ; create tool #2 M568 P2 R0 S0 ; set initial tool #2 active and standby temperatures to 0C M563 P3 S"Y Stand Alone Mode" D1 H2 F1 ; create tool #3 M568 P3 R0 S0 ; set initial tool #3 active and standby temperatures to 0C -

@HugoZM From your posts, I imagine you run a 6HC with a PanelDue attached, no boards on the CAN bus, and you control your printer from a PC running DWC (Duet Web Control) in a browser. The PC is connected via ethernet, not over USB. Please correct me if I’m wrong, I can’t see your setup from over here.

Something went wrong with the

M122report - it should begin with something like this:code_text `` === Diagnostics ===After the ethernet connection is lost, you can’t call

M122from DWC any longer - in this case, restart the Duet and invokeM122immediately afterwards. By this, you can copy the report from the console. Yesterday, you were able to post such a report on @Phaedrux’ request.Looking at yesterday's report, you are on RepRapFirmware version 3.5.1 - did you follow @Phaedrux’ advice to update the firmware to 3.5.4? And: which version is your DWC? (You can find this in the Settings / General tab of DWC).

To locate the LEDs on the 6HC, this Wiring Diagram is helpful. Most LEDs are located near the bottom left of the diagram. Within the 6HC’s Hardware Overview, the LED’s meanings are listed here.

Check the voltages (V_FUSED, 12V+, 5V+, 3.3V+, USB) and the STATUS LED after boot, then look if something has changed after the loss of ethernet.

If the LEDs give no hints, try the following:

- home Y, wait for ethernet to disconnect

- unplug the ethernet cable on both ends, wait a second, plug it back in: does DWC reconnect?

- If the error persists, try another ethernet cable

Please post your findings …

-

@HugoZM My guess is that you have mis-wired the endstop switch so that when it is triggered, it shorts out the 3.3V rail or the 5V rail. If that's the case then you will see the red 5V or green 3.3V LED go out when you trigger the endstop switch.