Does Duet support this kind of Kinematics?

-

This looks like an interesting take on a Cartesian motion system. Does duet support this?

Is it just a matter of editing the "Advanced core kinematics settings" in RRF Config tool?

-

undefined gwatson90 deleted this topic

undefined gwatson90 deleted this topic

-

undefined gwatson90 restored this topic

undefined gwatson90 restored this topic

-

Apologies all, This is the Markforged Kinematics. Next time ill look before i post!

-

No problem at all.

-

@gwatson90 said in Does Duet support this kind of Kinematics?:

Apologies all, This is the Markforged Kinematics. Next time ill look before i post!

I built one and it worked fine although the bed was only 300x200.

I also tried something new for me, triple Z steppers using built-in planetary gearboxes and belt drive.

Watching it auto-level was interesting - I have a video out on YourTube.

And the belt drive was nice and quiet compared to lead screws.

Frederick

-

Interesting belt layout.

I'm currently debating how to add an additional horizontal axis to my printer.

I am slightly nervous about pulling the Y axis from one side - as per the kinematics you are investigating - as I wonder if the gantry will stay straight - so will probably go for double y axis belts (as per Ratrig VCore4 Idex) - but that does mean two motors for one additional axis.

I guess with your kinematics the Y gantry will get pulled slightly from the left side too due to the friction from the 3 idlers and the print head bearings.

-

@dwuk

My design had two Y steppers which solved the problem you are concerned about.

The printer worked well but it was an experiment and I wasn't happy with having a bed 200 x 300.

Frederick

-

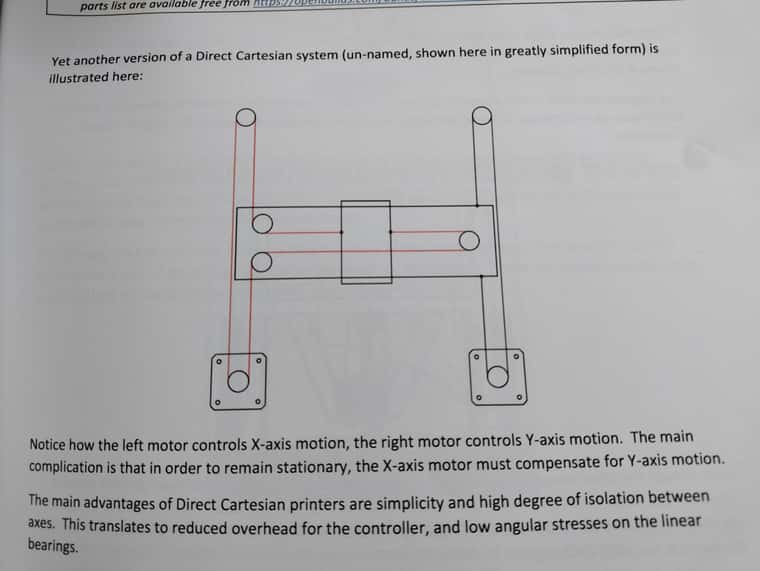

@dwuk I also have a minor concern about driving the Y Axis from one side. However I don't think that this motion system is subjected to the same kind of "Racking" forces as an H-Bot. Depending on your build volume you can probably get away with adding just making your XY motion system sufficiently rigid and appropriately dimensioned for the task as MarkForged seems to have done here.

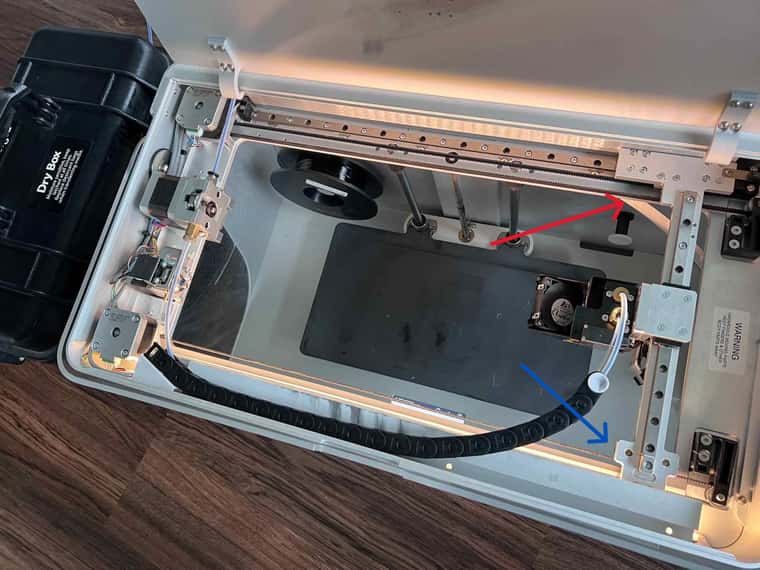

Notice on the Y drive side (Red Arrow) they are running two guides. A single guide would behave like an axis of rotation when subjected to moment loads while using two guides leads to more lateral loading of each guide which they are much more capable of handling while minimizing deflection. This is a small detail that makes a big difference.

The other side (Blue arrow) only has one guide. You could have a belt driven rotary shaft drive both Y axis belts eliminating the need for the third motor.

If you decided to follow the route that MKFG did here be mindful that adding a second guide to your rail could cause binding or non-smooth motion if your mounting surfaces to the rail mount or X-Axis member are not sufficiently flat.

My next build will be 350x350 so for the sake of overkill I'm just going to use two guides on each Y rail and drive both ends of the X- Axis member.

-

@gwatson90 Interesting idea having two rails.

It is amazing how well those linear rails work - for short things like little extra Z Axis' I am putting in my printer - without a linear rail they need a lot of lifting force, but when you add in a linear rail and push from quite a long way off the to side they still work quite well.

Mine build surface is currently 350x350 - but I would like to go at least 100mm larger - so I suppose I should stick to two belts - just a shame as that means two extra motors per extra axis on a flying gantry.

-

@dwuk Is the build you currently have in your profile pic?

-

@gwatson90 Yes - the profile pic is the dual gantry single extruder version. I am planning on adding a 2nd extruder to each gantry - which is why I am adding a 3rd Horizontal Axis to each one. - Background in this thread..

https://forum.duet3d.com/topic/37250/sovol-sv08-multiple-motion-system-upgrade