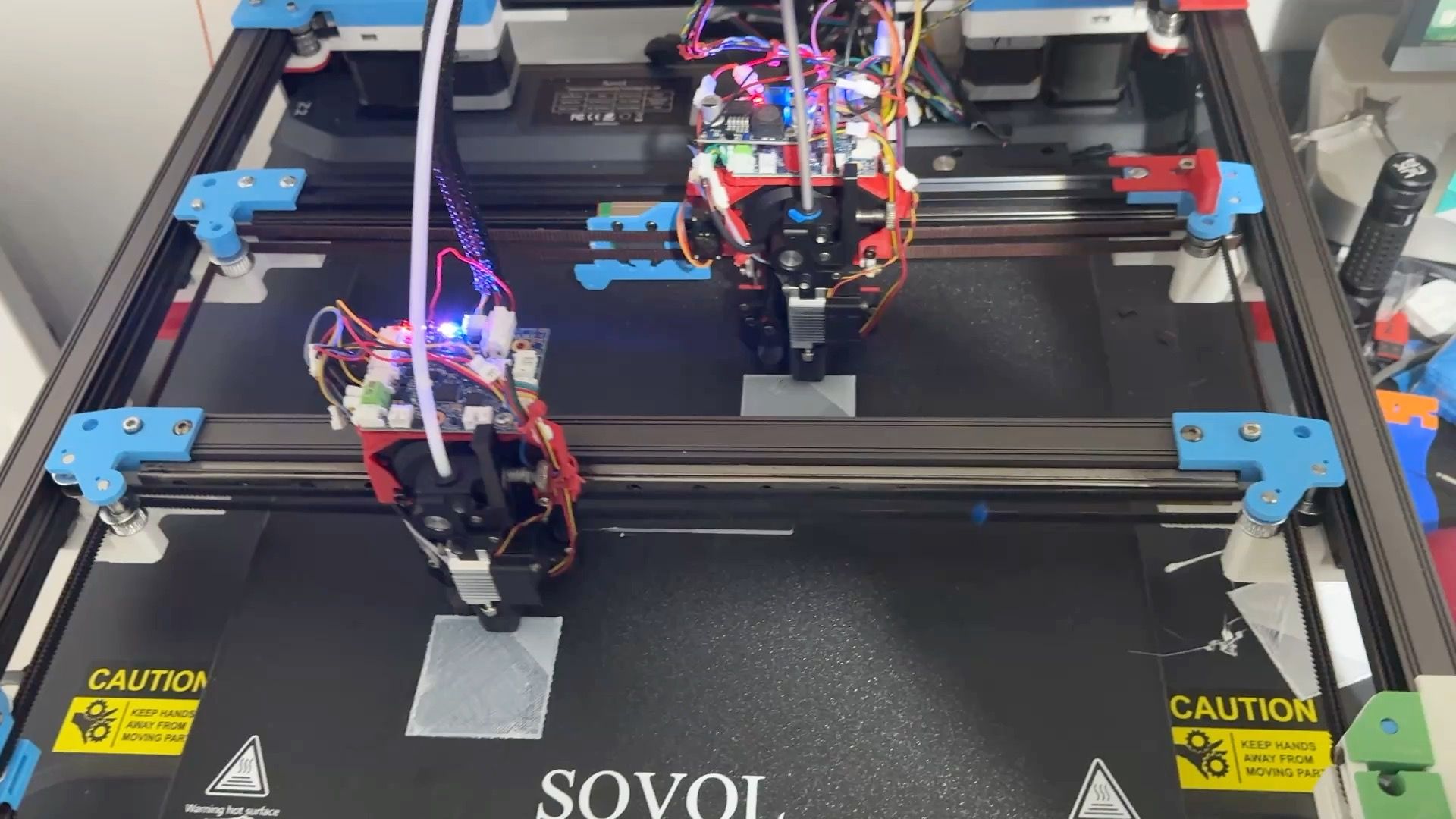

Back to printer -

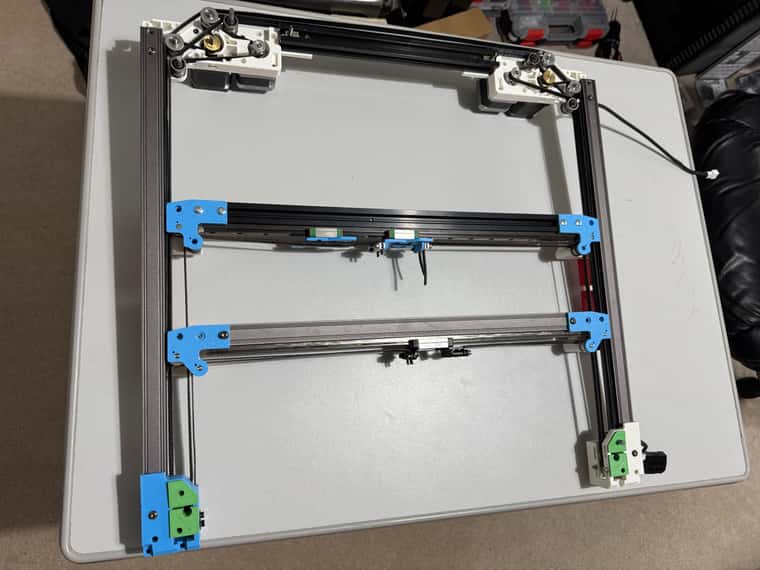

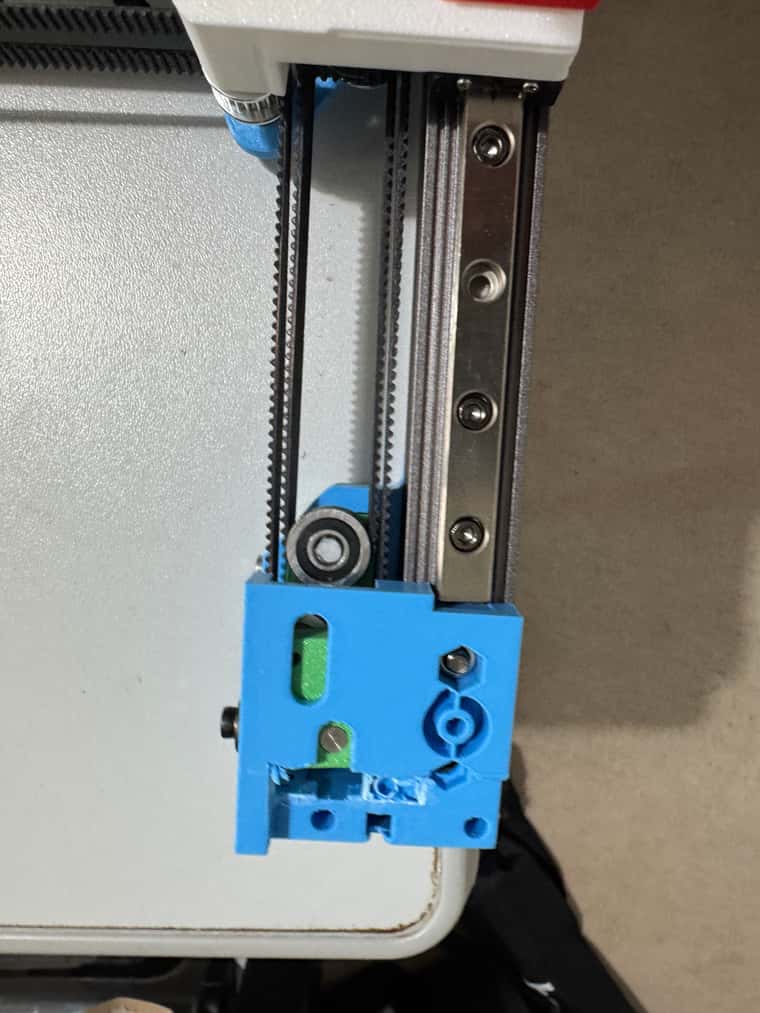

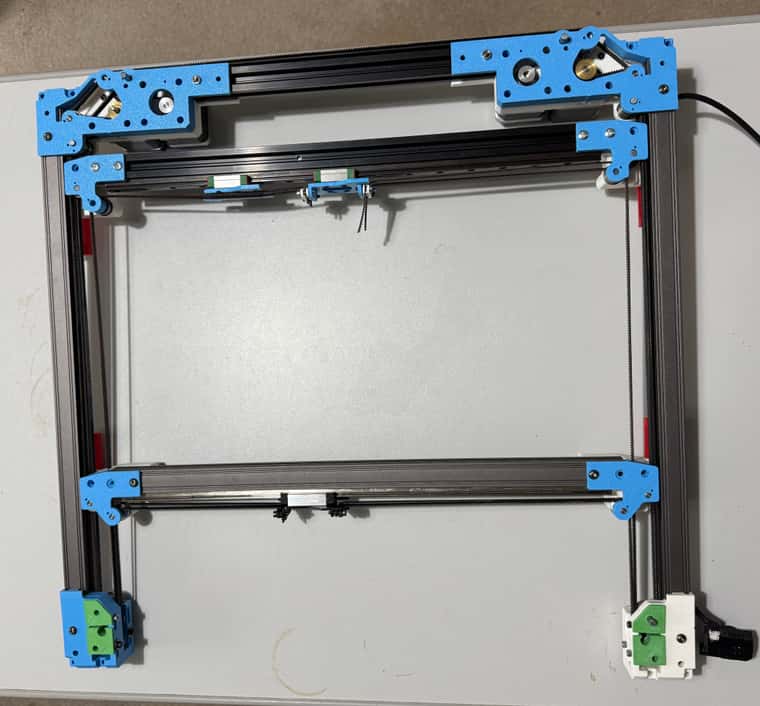

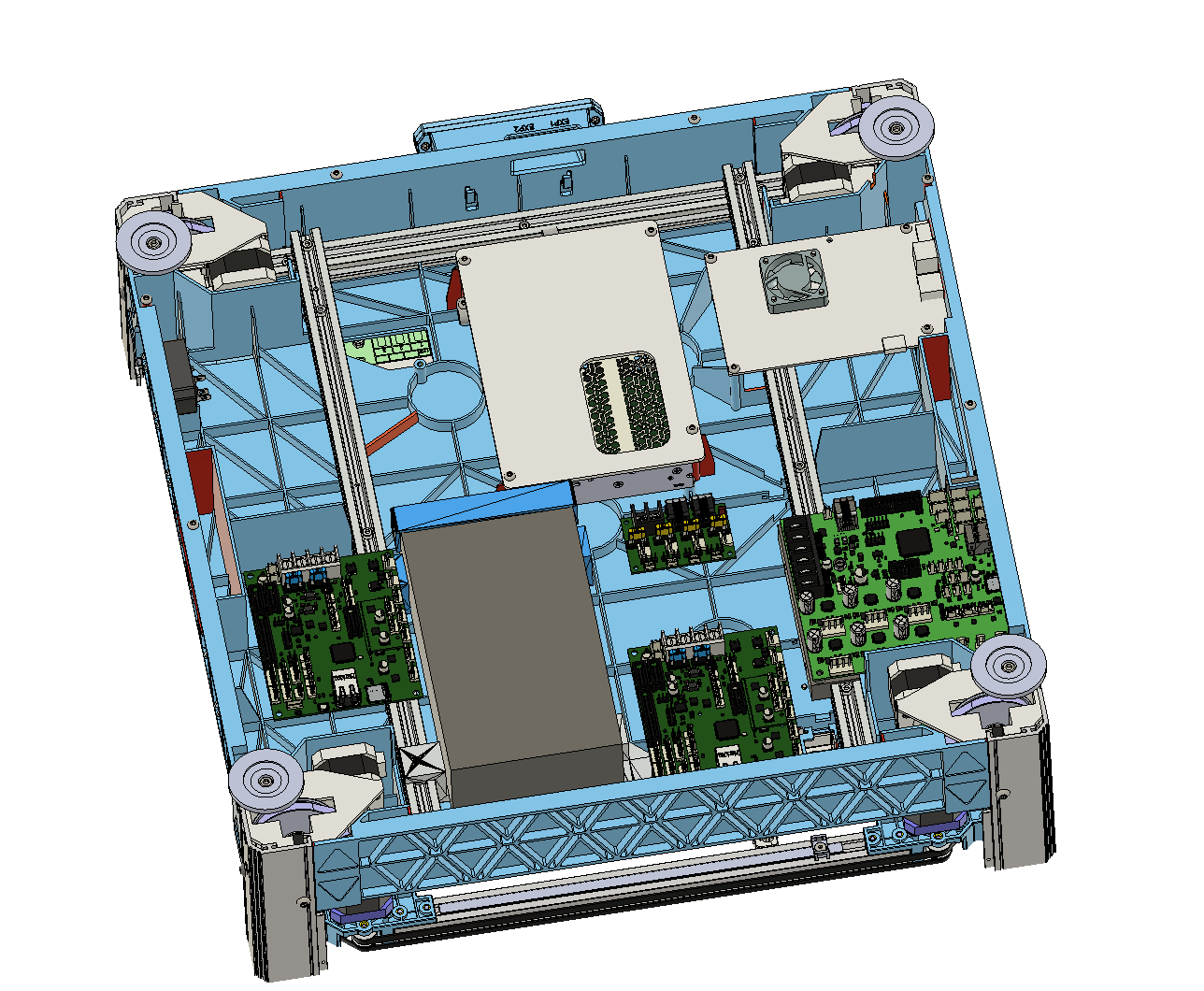

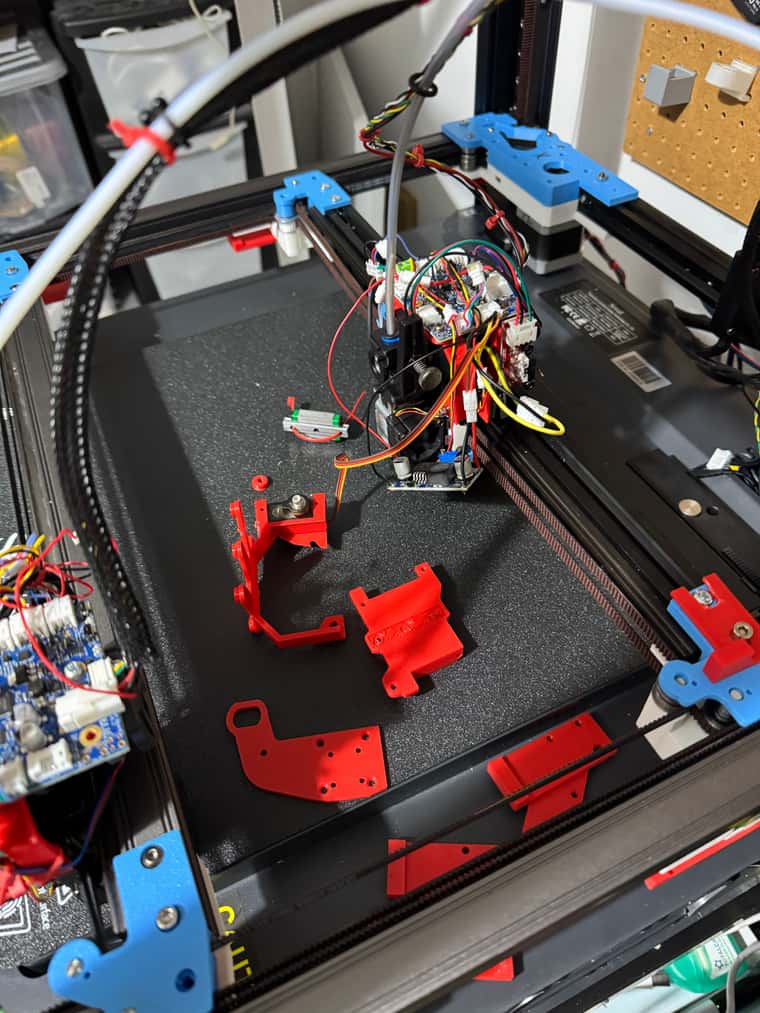

New Z Hopper motors arrived - bought full linear actuators - which I will take apart - as seems to be most cost effective way to source Nema 11 lead screw motors

Tap sensoring now working.

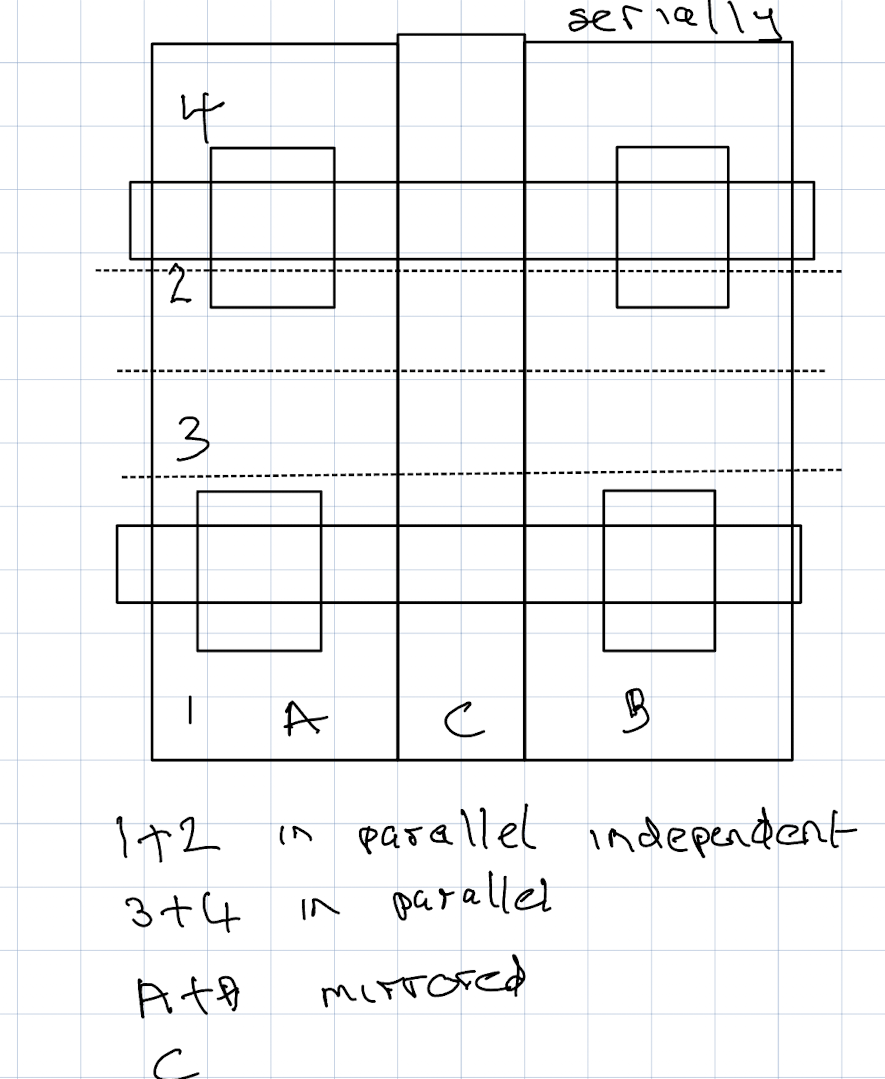

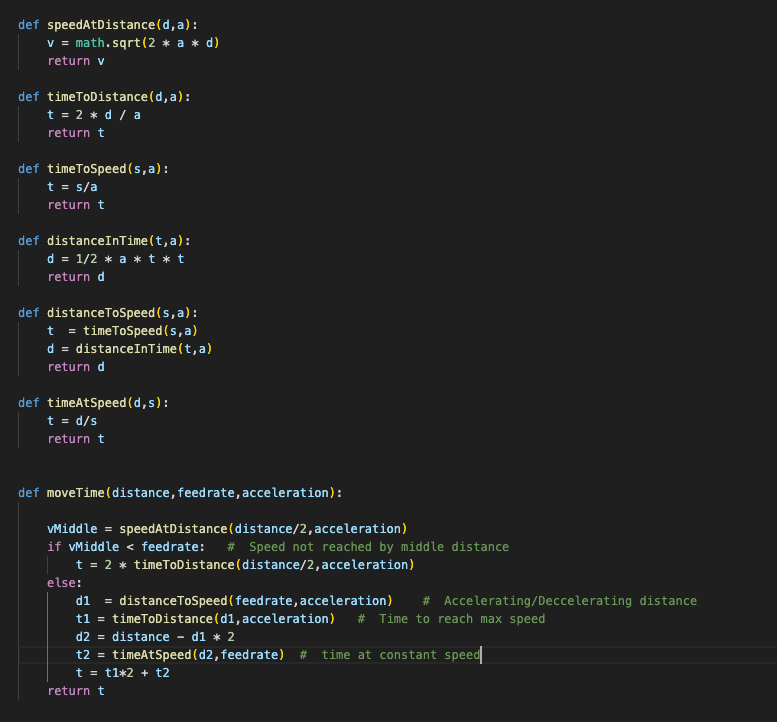

Logic is

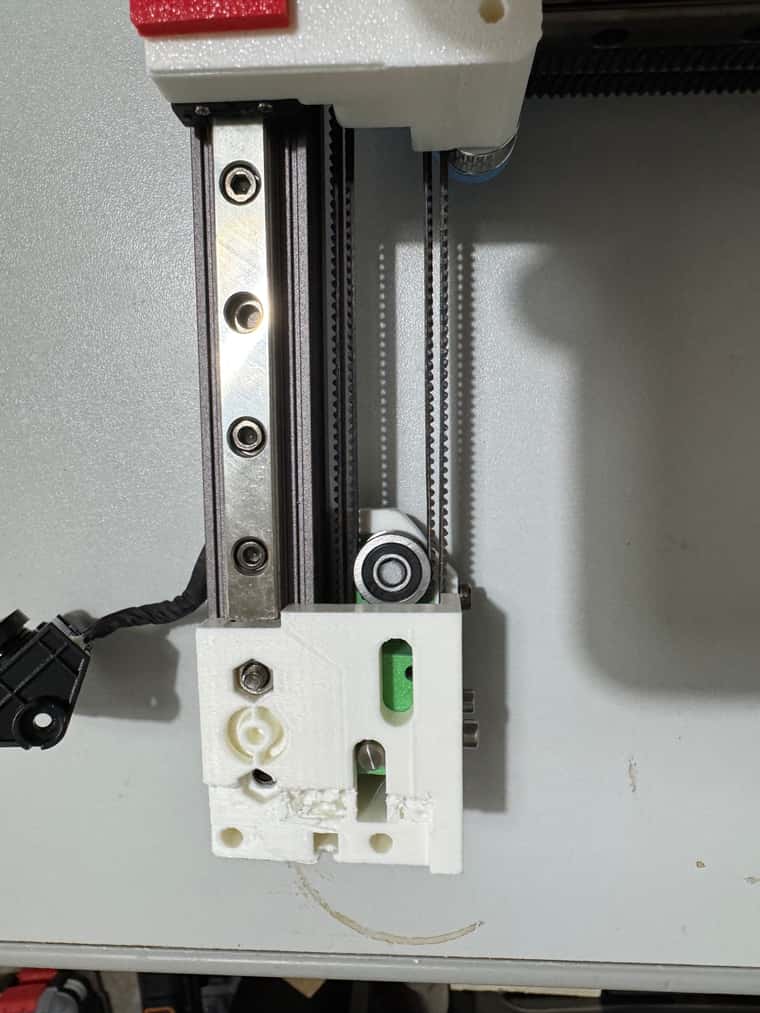

1.Home All

2. G32 Z motor alignment

3. Then for each print head

4. Move other print heads 2mm up so that they are out of the way

5. Align Z hopper to just trigger optical sensor

6. Move head down about 0.02 mm to just past the trigger point.

7. Switch probes/endstops so that the Z axis now has the Z hopper end stop as its trigger. (inverted)

8. Move Z down until print head hits to bed and then pushes up slightly within the play of the print head to disable the triggered optical sensor.

9. Repeat for various points of the print bed,

Short demo - showing tapping and play/flex - which might end up being a problem

https://youtu.be/5FGALqWV4t8

Example Tap test macro.

;tap A.g

M98.1 A"B On"

;reset probes to correct values

M574 Z1 S2 K0; configure Z axis endstop

M574 A1 P"122.io2.in" S1 ; configure A axis endstop

G90

G1 Z3 F1000

G1 D{global.dOffset+2} F1000

G1 B{global.bOffset+2} F1000

var speed = 400

;var w = {224, 224, 324, 324}

;var v = {310, 210, 210, 310}

var w = {160, 200, 200, 160, 324}

var v = {160, 160, 240, 240, 310}

var point1 = -1

while iterations < 5

var iGrid = iterations

G1 W{var.w[var.iGrid]} V{var.v[var.iGrid]} F10000

;echo "W",var.w[iterations],"V",var.v[iterations]

while iterations < 2

M574 Z1 S2 K0; configure Z axis endstop

M574 A1 P"122.io2.in" S1 ; configure A axis endstop

var aMax = 0

var aPos = 0

var aMin = 99

while iterations < 1

G1 A3 F{var.speed}

M400

var aProbe = sensors.endstops[6].triggered

if var.aProbe

abort "A Probe already triggered"

G1 H4 A-2 F{var.speed}

set var.aPos = move.axes[6].machinePosition

;echo "D trigger pos",var.dPos

if var.aPos > var.aMax

set var.aMax = var.aPos

if var.aPos < var.aMin

set var.aMin = var.aPos

var aProbe = false

if var.aMax-var.aMin > 0.03

echo "variation",var.aMax-var.aMin,var.aMin,var.aMax

while iterations < 4

;echo "i",iterations

G1 A{var.aPos-0.01*iterations} F{var.speed}

M400

set var.aProbe = sensors.endstops[6].triggered

if !var.aProbe

abort "A Probe not triggered"

else

if iterations > 1

echo "lowered head ",0.01*iterations,"mm"

break

M574 A1 P"122.io3.in" S1 ; configure A axis to temporary Endstop

M574 Z1 P"!122.io2.in" S1 ; configure Z Axis to A end stop inverted

var zPos = 0

G1 Z{var.zPos+2} F500

M400

set var.aProbe = sensors.endstops[2].triggered

if var.aProbe

abort "AZ Probe already triggered"

G1 H4 Z-7 F{var.speed}

set var.zPos = move.axes[2].machinePosition

if var.point1 == -1

set var.point1 = var.zPos

echo "A zPos",var.zPos,"W",var.w[var.iGrid],"V",var.v[var.iGrid],"point",var.iGrid,"var",var.zPos-var.point1

G1 Z3 F1000

;restore probes

M574 Z1 S2 K0; configure Z axis endstop

M574 A1 P"122.io2.in" S1 ; configure A axis endstop

; 122.io3.in - dummy endstop when A swapped out