Extruder skips mid print randomly/Infill pattern problem

-

I managed to get the print better, but the skipping that is happening is still ruining the prints. Any ideas?

Check your extruder stepper wires. It is possible you're only running on one coil because one wire is off , broken or otherwise disconnected. Also check you've got your current for that motor high enough.

-

I just had a look at the video and it looks a bit to me like the extruder does a retract but it's not followed by an unretract. Very odd behaviour…...

Check through the gcode file and see if you can spot any negative extruder moves that are not immediately followed by a positive extruder move. It looks like you are using 8mm retraction (which is a bit high) so you'll be looking for something like G1 E-8 followed by G1 E8.

Thinking about it a bit more, another possibility is that you are suffering from heat creep, causing the filament to swell in the area of the heat break. So when you do a (8mm) retract, it pulls some of the molten filament up beyond the heat break where it partially solidifies, binds, and prevents the extruder from pushing the filament back down during what should be the unretract move. A quick test would be to set retraction to zero (ooze control), slice it like that and see if things improve.

HTH

-

Ian's post alerted me to the fact that you posted a video, which I hadn't noticed before. I'm fairly sure that your extruder drive is skipping steps because it isn't producing enough drive force. That's why it doesn't skip on the outlines, because they are printed more slowly so less force is needed.

You are using an ungeared extruder, so this is not unusual. What model of stepper motor are you using to drive it? I see that you have the extruder motor current set to 800mA. If that's less than 85% of the stepper motor rated current, try increasing it.

-

Good catch David. I hadn't spotted the extruder steps per mm set to 92 which would indicate an ungeared extruder. Heat creep may also be playing a part which would be exacerbated by using an ungeared extruder. As you say, increasing the motor current if possible will help, as would changing to 24V if the OP is using 12V (couldn't see anything to indicate what the PSU is).

-

Changing to 24V won't help unless the motor is a low current high voltage one, because extruder motor speed isn't the problem.

-

That's true. I'd forgotten that we are talking about low speeds.

-

1. All of the stepper wires have good connections.

2. These are the exact motors I have. https://www.aliexpress.com/item/New-Arrival-5PCS-Wantai-Nema17-Stepper-Motor-42BYGHW609P1-Single-Flat-4000g-cm-40mm-1-7A-4/2047689916.html

3. 850 was my current, but someone had suggested to bring it down a little bit to see if there was a difference (brought it to 800, no difference)

4. It is all 12v. I am planning to upgrade at some point in the near future. Just wanted to get all the kinks worked out first.

5. At 92 steps it pushes out the correct amount of filament every time.

UPDATES:

1. I decided to hook up the FSRs and give it one more try ( i couldn't get it working right so went back to springs) and somehow am getting a GREAT skirt and first layer, but that jerk is not happening anymore, but it's still skipping but in a different way now.2. It's acting like the extruder is trying to give the hotend too much filament and it is forcing the filament to start popping out of the gear threads, which is taking pressure off of the filament and the filament stops coming out for those little periods then it catches back up and starts laying filament down again. It usually only stops for like 4-10 lines.

3. I turned retraction off. issue didn't change.

4. I brought the current back to 850. issue didn't change.

I appreciate you guys trying to help out. I'm at a concrete wall right now, and beginning to lose hope lol

-

What happens when you jack the current up to like 1.2 or 1.4A ?

Going from 800 to 850 is like nothing…50mA is nothing to these motors.

-

Check through the gcode file and see if you can spot any negative extruder moves that are not immediately followed by a positive extruder move. It looks like you are using 8mm retraction (which is a bit high) so you'll be looking for something like G1 E-8 followed by G1 E8.

HTHI looked through the code and I do see the "G1 E-8.0000 F2500"

the "G1 E8.0000 F2500" is a couple lines down.G1 E-8.0000 F2500

; layer 12, Z = 2.380

; inner perimeter

G1 X9.280 Y-9.280 F4800

G1 Z2.380 F1000

G1 E8.0000 F2500 -

So the same issue is happening when i just warm up the printer and extrude from web control. So i don't think it's an Simplify3D issue

-

Does the problem occur if you extrude into free air at 4mm/sec ? e.g. with the nozzle hot and clear of the bed, send G1 E100 F240.

If the extruder drive is losing its grip on the filament, you may need to increase the pressure adjustment in your extruder drive.

if it is maintaining its grip but the extruder drive skips back occasionally as indicated in your video, you need to increase the extruder drive current. I suggest 1400mA.

If the hot end is getting blocked, check that the heatsink fan is running continuously and keeping the heatsink cool.

-

1. Problem does occur if I extrude in free air using G1 E100 F240. Alot actually

The extruder drive is loosing it's grip on the filament, but I think that it's more of the extruder is trying to give it more filament than needed, or the hotend is having trouble pushing the filament out as needed.

The first layer and half of the second layer print perfectly, for it to do it randomly but never on the first layer. It just seems like if it was because it wasn't gripping right it would be doing it more often.

2. I did raise the current up to 1400mA and had the same results, so I brought it back down to 850mA.

3. Hotend isn't getting blocked, apart that it is brand new and I haven't really been able to print all that much, the fan is running 100% and the heatsink is cool to the touch.

-

The one thing that is making this weird, is that I just upgraded to a DuetWifi and I had none of these issues when I was on RUMBA. I meant that as another clue, not as a comparison.

-

When I tightened the tensioner more it got rid of the filament skipping, but then it started doing "the video" thing at about the same frequency as the skipping was.

-

Could it be a temperature calibration issue? For a given indicated temperature, the actual temperature may have been higher on your RUMBA setup than it is on the Duet. So you might be extruding at a lower temperature than before, resulting in more back pressure from the hot end.

Have you configured the correct thermistor parameters in the M305 P1 command in config.g?

-

I've used temps for this spool of PLA from 190 to 210 with the same results.

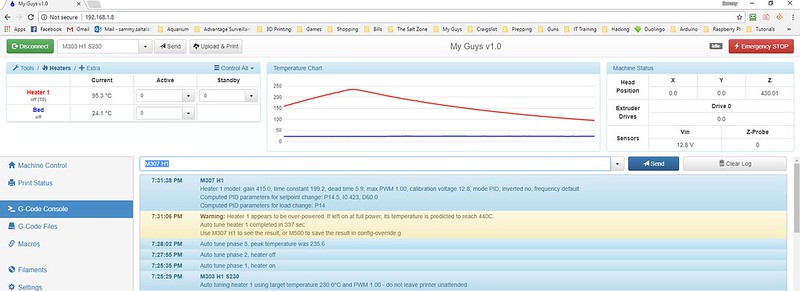

I have run a M303 H1 S240 twice, once before i hooked anything up to the hotend (just bought it a couple weeks ago), and once with filament through it, fan on, and sock on

-

Hmm.. I just ran it again and now all of a sudden it says

Warning: Heater 1 appears to be over-powered. If Left on at full power, it's temperature is predicted to reach 447C.

Auto tune heater 1 completed in 355 sec

Use M307 H1 to see the result, or M500 to save the result in config-override.gI was staring at the temp for like 90% of the test, the highest it got was 248, and it didn't send that message until it said it was completed. Even then it was cooled down to around 140 when that message got sent.

-

-

What do you think doesn't make sense? That message is produced when the firmware has calculated the heating parameters, which it can't do until it has measured the cooling rate. It's common to see that message ever since E3D introduced the silicone socks.

-

What do you think doesn't make sense? That message is produced when the firmware has calculated the heating parameters, which it can't do until it has measured the cooling rate. It's common to see that message ever since E3D introduced the silicone socks.

Oh, I didn't know. Just didn't know if I should save it since it was saying 440c.