Extruder skips mid print randomly/Infill pattern problem

-

When I tightened the tensioner more it got rid of the filament skipping, but then it started doing "the video" thing at about the same frequency as the skipping was.

-

Could it be a temperature calibration issue? For a given indicated temperature, the actual temperature may have been higher on your RUMBA setup than it is on the Duet. So you might be extruding at a lower temperature than before, resulting in more back pressure from the hot end.

Have you configured the correct thermistor parameters in the M305 P1 command in config.g?

-

I've used temps for this spool of PLA from 190 to 210 with the same results.

I have run a M303 H1 S240 twice, once before i hooked anything up to the hotend (just bought it a couple weeks ago), and once with filament through it, fan on, and sock on

-

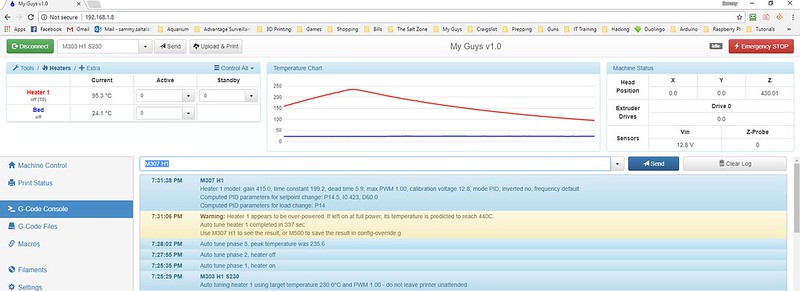

Hmm.. I just ran it again and now all of a sudden it says

Warning: Heater 1 appears to be over-powered. If Left on at full power, it's temperature is predicted to reach 447C.

Auto tune heater 1 completed in 355 sec

Use M307 H1 to see the result, or M500 to save the result in config-override.gI was staring at the temp for like 90% of the test, the highest it got was 248, and it didn't send that message until it said it was completed. Even then it was cooled down to around 140 when that message got sent.

-

-

What do you think doesn't make sense? That message is produced when the firmware has calculated the heating parameters, which it can't do until it has measured the cooling rate. It's common to see that message ever since E3D introduced the silicone socks.

-

What do you think doesn't make sense? That message is produced when the firmware has calculated the heating parameters, which it can't do until it has measured the cooling rate. It's common to see that message ever since E3D introduced the silicone socks.

Oh, I didn't know. Just didn't know if I should save it since it was saying 440c.

-

And how about the bowden path? If you feed it by hand, do you find any resistance?

I once had a filament that was just a bit thicker and it got stuck inside the bowden tube. -

So should I save the M303 results even thou it says something about 400c?

-

And how about the bowden path? If you feed it by hand, do you find any resistance?

I once had a filament that was just a bit thicker and it got stuck inside the bowden tube.Nah no resistance when I push it through. The tube itself is maybe 2 weeks old.

-

I have checked and calibrated extruder steps and current.

I swapped stepper drivers.

I changed stepper motor wiring.About to put it my previous hotend and see if I get the same issue…

-

What happens when you jack the current up to like 1.2 or 1.4A ?

Going from 800 to 850 is like nothing…50mA is nothing to these motors.

When i bring it to 1.4A, it acts the same.

-

I put my previous E3D v6 on the printer, and the same happens

-

Extruding 10mm of filament at 5mm/sec, skips the entire time

-

Hi Saltlife,

From what I can see, the temperature is one of the issues, so you should just raise up to 220 degrees minimum if not 230!

Your extruder is fine printing the skirt because S3D give usually less plastic during the process.

The temperatures reading change every time from a board to another, it doesn't mean that Duet is wrong, you should try to point an IR probe to the heater and see what is really going on near the nozzle.

Your extruder shouldn't skip steps as in the video, should grind the filament instead, so, I would raise the current to a decent amount and then step back until the motor is running fairly warm if you don't know the motor technical details.

The motor is not retracting, is just the effect of the stall, the filament act as a spring as your is a Bowden and the pressure is just doing that because the moment your motor stall, the rotor has no more torque and become loose.My 2 cents

Regards -

Hi Saltlife,

From what I can see, the temperature is one of the issues, so you should just raise up to 220 degrees minimum if not 230!

Your extruder is fine printing the skirt because S3D give usually less plastic during the process.

The temperatures reading change every time from a board to another, it doesn't mean that Duet is wrong, you should try to point an IR probe to the heater and see what is really going on near the nozzle.

Your extruder shouldn't skip steps as in the video, should grind the filament instead, so, I would raise the current to a decent amount and then step back until the motor is running fairly warm if you don't know the motor technical details.

The motor is not retracting, is just the effect of the stall, the filament act as a spring as your is a Bowden and the pressure is just doing that because the moment your motor stall, the rotor has no more torque and become loose.My 2 cents

RegardsI will try raising the temp to 220 when I get home and see if that works. Thanks.

-

So should I save the M303 results even thou it says something about 400c?

Just to clarify this message means that if the heater cartridge is allowed to draw full power, with no control, it could reach about 440C. This is not a configured parameter its a warning generated to make you aware that the max temperature if the control fails could get to a dangerous level. This is not control electronics specific but dependent on the heater cartridge, your power supply voltage, and the cooling rate of the heatblock (which is changed by having a silicone sock on it).

So yes you should save the results using M303, and also be aware that an electronics failure could lead to a very hot hotend!

-

Actually 440C is not nearly as hot as I sometimes hear reported, in particular nowhere near hot enough to melt the aluminium.

-

Ok I'll redo the PID test and save it then. But guys.. Listen to this. Trojan3D was on point with the hotend temp…

I ended up buying a brand new spool of Hatchbox filament, loaded it up, set temp to 200c. It worked PERFECTLY... Put in the old filament at 200c, then I got the same problem, brought the temp up to 220, and it started printing perfectly...

So my problem was, for some reason, this PLA (and other PLA of same brand) needed to be at 220c in order to print correctly..

-

And yes all of my filament rolls are in individual 2 gallon ziplocs bags with the "keep dry" packs in them.