Printing Settings problem

-

I'm reading :

This material doesn’t need to be squeezed onto your heated bed, you want to leave a slightly larger gap on the Z axis to allow more room for the plastic to lay down. If the extruder nozzle is too close to the bed, or previous layer it will skim and create stringing and build-up around your nozzle. We recommend starting off moving your nozzle away from the bed in 0.02mm increments, until there is no skimming when printing.How can I set on config.g to increments the height?

-

I usually run petg with a hotend at 240-250c I get my best prints that way. My bed is usually at 80-85c.

In my bridge testing petg had poor layer adheasion at 230c compared to 240c, 240 was the middle for me. I do run the first layer hotter than the rest. 220c imo is too cold to extrude correctly imo, especially for esun petg (what i use)

-

You can use baby stepping in the DWC to raise the height of the print head during a print. Alternatively you can set a Z offset in your slicer.

I find that PETG doesn't really like to stick to bare painters tape very well. Usually something like gluestick is applied to the bed first.

I would suggest that before you try and increase the layer height, since you're already at 0.4, try adding a coating of gluestick to the bed first, and reduce your first layer speed to 15mm/s. I like to use a higher bed and nozzle temp for the first layer as well, 85/245.

-

240-245/85 ....seems perfect....I'll try another run to see the result

-

I do petg at 245 hotbed and 85 to 95 bed temp, is on blue tape I use gluestick or on glass I use hairspray

-

glue stick works well, I used that for a while before i spent 70 dollars for a pei sheet worth it imo. As Pheadrux said, lower the speed for the first layer. Even with a PEI sheet i still run mine slow (20mm/s).

Another note, I personally use Slic3r for prints that have a bunch of holes that print on the heat bed. It handles holes better than Cura for me.

-

Looking at you prints I can tell you from experience, If you do not give up you will get this, Your stuff looks exactly like mine used to. It gets easier over time and eventually you just look at something and know what to change. When you make changes have some patience and only change one setting at a time in the beginning, then evaluate whether or not your change did what you thought it would.

-

Printed some object with some "error":

I tried to start the first layer with 245/85 and the other layers with 230/60.

Retraction setting with 3mm .I need to change something else to fix this errors...

-

Try reducing your extrusion factor a few percent. Since PETG is so sticky it's very susceptible to gumming up if it's over extruded.

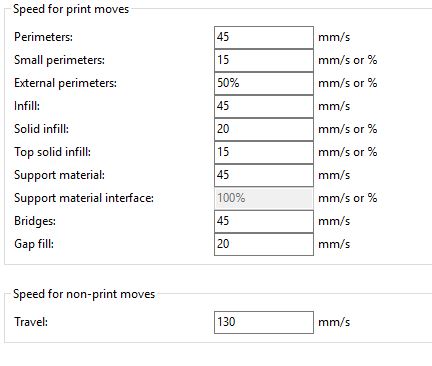

What speed was that printed at?

-

-

PetG for me: Hairspray on top of the blue tape. OR, Kapton tape.

230 on hotend, 85 to 90 on bed.

-

@phaedrux I tried to lower the extrusion factor from 100 to 96% and seems better....but I've to lower again...there is some value ( lower value ) that we don't have to reach?

-

@bulka said in Printing Settings problem:

@phaedrux I tried to lower the extrusion factor from 100 to 96% and seems better....but I've to lower again...there is some value ( lower value ) that we don't have to reach?

You can set the extrusion factor as low as you like. If you have calibrated your extruder steps/mm then it's unlikely that you need to go lower than about 95%.

-

@dc42 ok . I calibrated my extruder steps/mm to extrude exactly the amount requested but i want to fix the gumming produced. There is something else ( parameter ) to fix to reduce that ? Or is something that with PETG is normal and impossible to go to 0 ?

-

@bulka said in Printing Settings problem:

@dc42 ok . I calibrated my extruder steps/mm to extrude exactly the amount requested but i want to fix the gumming produced. There is something else ( parameter ) to fix to reduce that ? Or is something that with PETG is normal and impossible to go to 0 ?

I rarely print PETG so I'm not an expert with it. By all means reduce the extrusion factor further if that helps.