Your Duet rejected the HTTP request: page not found

-

Well every other 3d printer company offers support and I can spend time chatting with them learning about their machines. And recieve normal troubleshooting help and not have to use a forum to wait for a response. I know how my printers work. I know how the fw works, but this is another level of knowledge, and I am admitting my ignorance and requesting someone to take me by the hand and walk me through this like any other companies support would do if requested of them.

-

@phaedrux ok i will call robo3d and get the information thank you

-

@sleepless

Take it step by step.Get the connectivity working as @Phaedrux recommends. That said you do not need to reboot after every single change.

Once that is working check you have wired the printer in line with the wiring guide:

https://duet3d.dozuki.com/Guide/edit/9/46 -

@sleepless I'm sorry the speed of response isn't up to your liking. Please keep in mind that Duet is located in the UK and so you'll have to forgive any time zone delays. There are others who are very knowledgeable that can help, but the problem must be stated clearly so that a detailed response can be given. We need some detail about your problems to be able to respond. That's why there is documentation. It's a lot easier to spend a little time reading things over a bit since all your answers are contained within. Anything anyone tells you here will already be in the documentation in some form.

Now I'll be glad to give you a hand here, but you'll have to start giving some more details,

-

@sleepless what does the original control board of the Robo run? Alot of the information you need to configure the Duet for the printer will be available in the configuration of the old controller.

-

ok would you mind telling me a list off details I should provide? Ive been reading docs for the past week, so i am frustrated from hunting through them for answers when someone can quickly tell me an answer. I unfortunately dont have free time to sit around reading the docs, as it is the setup has had this machine down and my attention away from for for 4 days which I cant afford so it must get up and running today. I understand the time difference which is why i requested help from someone in USA

-

@sleepless said in Your Duet rejected the HTTP request: page not found:

@phaedrux ok i will call robo3d and get the information thank you

You may also be able to find the information from the existing configuration. I'm not familiar with the Robo3D R1. But if it's currently functioning you may be able to find the values on the LCD or in the firmware source if available. Maybe even a product website.

Here is some documentation on adapting a printer to use a Duet: https://duet3d.dozuki.com/Wiki/Going_from_Marlin_on_Arduino_to_RepRapFirmware_on_Duet

-

Adapting an existing printer to Duet

What mechanical and electrical details are needed to configure RepRapFirmware? What information is needed to configure an existing 3D printer to work with a Duet control board? Going from Marlin on Arduino to RepRapFirmware on DuetWhat information is needed to configure an existing 3D printer to work with a Duet control board?

Every 3D printer is different. And while mechanics are commonly shared, the specifics will vary greatly. Changing over an existing commercial 3D printer to use Duet electronics requires some basic mechanical and electrical knowledge of the printer. This information can usually be obtained from manufacturer documentation, or a quick google search. In a pinch you can measure. The details needed, and common values for them are found below.What mechanical details are needed to configure RepRapFirmware?

Steps per MM

Motor resolution

0.9° or 1.8° rotation per step

400 or 200 steps per revolution

Drive pulley tooth count

16T, 20T, 30T, 40T, 60T are common

Belt tooth profile and pitch

Timing Profile Example: GT2, GT3, MXL, HTD

Belt Pitch Example: 2mm, 3mm, 2.08mm, etc

Driver microstepping

Commonly 16 steps (A4988) or 32 steps (DRV8825)

Duet can use up to 256

Lead screw pitch and lead

Pitch = distance between threads

Lead = travel in mm for one revolution

TR8*8 are most common with a pitch of 2mm and a lead of 8mm

Gear Ratios

Extruder Gearing

Example: E3D Titan and BondTech extruders use 3:1 gearing.

Z Axis Gearing

Example: 20T drive gear and 40T gear on lead screw would be 2:1 gearing

Formulas

Online Steps Per MM Calculator (Google Sheets)

X and Y Axis]

xy_steps_per_mm = (motor_steps_per_rev ∗ driver_microstep) / (belt_pitch_mm ∗ pulley_number_of_teeth)

Z Axis

Z_steps_per_mm = (motor_steps_per_rev * driver_microstep) / thread_pitch

Extruder Axis

e_steps_per_mm = (motor_steps_per_rev * driver_microstep) * (big_gear_teeth / small_gear_teeth) / (hob_effective_diameter * pi)

Build Volume

Axis travel maximums

Print surface size

Z Probe to Nozzle XYZ offset

Origin location (0,0) AKA home position.

What electrical details are needed to configure RepRapFirmware?

Voltages

Power Supply

Commonly 12v or 24v

Fan Voltages

Most commonly 12v, but also available in 24v and 5v

Heater cartridge and bed heater voltage

12v or 24v common for heater cartridges and PCB heat beds. 120v or 240v for AC powered heat beds using an SSR

Max rated motor current in amps

Check the motor spec sheet if available, may need to find model number sticker on the motor

May be found in configuration.h or LCD menu of the printer

For optimal performance on the Duet target to set the current at 70-85% of max rated

Thermistor details

Type of thermistor

Thermistor, PT100, PT1000, Type-K Thermocouple

Thermistor table values if known

Max temp for bed and hotend

Endstop details

Endstop type: microswitch, optical, hall effect

Switch type: Active Low (Normally open), or Active High (normally closed)

Endstop position: High end or low end of travel

Z Probe details

Probe voltage

Probe trigger height

Probe voltage

What firmware details are needed to configure RepRapFirmware?

Speed settings

Acceleration and Jerk values

Can be found in LCD menu or in configuration.h

Extrusion multiplier

Z offset

Fan speeds

**Going from Marlin on Arduino to RepRapFirmware on Duet

Once you have these printer details you can use the RepRapFirmware Configurator to build yourself a starting config file set.If you're not sure what these values are for your printer, check with the manufacturer, check labels, check google, check the forums to see if someone else has already converted your model of printer, etc.

If you're coming from Marlin and have access to the configuration.h files you check there for some of the values.

Note: Marlin uses MM/s for feed rates, RepRapFirmware uses MM/Min. To convert from one to the other you must either multiply or divide by 60. Example: 100mm/s = 6000mm/min.

-

I understand your frustration. The initial setup can be a little daunting, but once it's out of the way it's out of the way. So some time up front is required. Duet isn't a 3D printer manufacturer, the board is meant to be flexible and configurable so it can fit into almost any situation. This means it's not exactly plug and play. For that you'd want to get a printer kit that comes with a Duet, or find a model of printer that has already been adapted and using someones already done config. But this is where we are, so lets get that duet working in the Robo3D R1.

-

@sleepless Looking at the Robo R1 page it looks like that printer uses a RAMPS board:

https://help.robo3d.com/hc/en-us/articles/115002569971-R1-RAMPS-Board-Wiring-Diagram

It looks like the firmware is here:

https://help.robo3d.com/hc/en-us/articles/115000723672-Robo-R1-original-firmwareIf those match your printer then a good start point is the configuration.h in the firmware to get the settings used on the Robo.

-

@phaedrux Motor resolution

Not sure what these are:

0.9° or 1.8° rotation per step

400 or 200 steps per revolution

Driver microstepping

// MS1 MS2 Stepper Driver Microstepping mode table

#define MICROSTEP1 LOW,LOW

#define MICROSTEP2 HIGH,LOW

#define MICROSTEP4 LOW,HIGH

#define MICROSTEP8 HIGH,HIGH

#define MICROSTEP16 HIGH,HIGH

my guess is 16 microsteps

according to the site the step motor is a:4.25V

1.7A

21-90 oz-in / 1.5-6.5 kg-cm

Hybrid

Extruder Gearing Where can I find this?Axis travel maximums

Answers:

steps per mm

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,800,723.38} x,y,z,eTR8*8 are most common with a pitch of 2mm and a lead of 8mm

20t gt2 belt

(dont know pitch but i think its 2mm)i copied this from the marlin fw

// actual motor currents in Amps, need as many here as DIGIPOT_I2C_NUM_CHANNELS

#define DIGIPOT_I2C_MOTOR_CURRENTS {1.0, 1.0, 1.0, 1.0, 1.0, 1.0, 1.0, 1.0}psu is 12v amps

Z Probe details: uses two endstops to trigger its autohoming

-

[0_1540502855300_ROBO3DR1PLUSV2.ino](Uploading 100%)

heres a copy of their fw -

havent been able to reconnect to the browser since i powered off and on the duet... What did i break?

-

@sleepless said in Your Duet rejected the HTTP request: page not found:

@phaedrux Motor resolution

Not sure what these are:

0.9° or 1.8° rotation per step

400 or 200 steps per revolution

Driver microstepping

// MS1 MS2 Stepper Driver Microstepping mode table

#define MICROSTEP1 LOW,LOW

#define MICROSTEP2 HIGH,LOW

#define MICROSTEP4 LOW,HIGH

#define MICROSTEP8 HIGH,HIGH

#define MICROSTEP16 HIGH,HIGH

my guess is 16 microstepsThats is a good assumption.

according to the site the step motor is a:

4.25V

1.7A

21-90 oz-in / 1.5-6.5 kg-cm

Hybrid

Extruder Gearing Where can I find this?With the steps/mm you have reported below this lets us know that the Extruder stepper is 723.38 steps/mm so you don't need to know the extruder gearing.

Axis travel maximums

Answers:

steps per mm

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,800,723.38} x,y,z,eTR8*8 are most common with a pitch of 2mm and a lead of 8mm

20t gt2 belt

(dont know pitch but i think its 2mm)i copied this from the marlin fw

// actual motor currents in Amps, need as many here as DIGIPOT_I2C_NUM_CHANNELS

#define DIGIPOT_I2C_MOTOR_CURRENTS {1.0, 1.0, 1.0, 1.0, 1.0, 1.0, 1.0, 1.0}psu is 12v amps

Z Probe details: uses two endstops to trigger its autohoming

This Z probe configuration sounds different from something I have come across before. How does it do this? -

@sleepless How is the Duet installed? inside the metal box? If so then Wifi communications is likely to be difficult.

Please work thoguh this guide:

https://duet3d.dozuki.com/Wiki/WiFi_disconnections_and_AJAX_timeout_errorsEspecially look at the reported Wifi signal strength if you have it in an enclosure that could be blocking WIFI.

-

@t3p3tony

At the base of the robo3d r1plus where the ramps board used to be. I tried uploading a photo from my phine but seem to be having issues. I will upload a photo from my computer. By the way since its a Greg wade extruder on the robo3d its a 4:1 gear ratio -

Thanks I will try the WiFi troubleshooting and keep you posted

-

I conntected to my pc and ran m552 saw wifi was idle so i ran m552 s1and it got the ip again. still cantconnect from browser though. I ran m122 and got

=== Diagnostics ===<LF>RepRapFirmware for Duet 2 WiFi/Ethernet version 2.0(RTOS) running on Duet WiFi 1.02 or later<LF>Board ID: 08DGM-9T6BU-FG3SJ-6J9D4-3S86T-TAXRD<LF>Used output buffers: 1 of 20 (10 max)<LF>=== RTOS ===<LF>Static ram: 28380<LF>Dynamic ram: 95784 of which 0 recycled<LF>Exception stack ram used: 300<LF>Never used ram: 6608<LF>Task NETWORK ready, free stack 1272<LF>Task HEAT blocked, free stack 1256<LF>Task MAIN running, free stack 3656<LF>=== Platform ===<LF>Last reset 00:09:07 ago, cause: power up<LF>Last software reset at 2018-10-24 20:24, reason: User, spinning module GCodes, available RAM 6152 bytes (slot 0)<LF>Software reset code 0x0003 HFSR 0x00000000, CFSR 0x00000000, ICSR 0x0041f000, BFAR 0xe000ed38, SP 0xffffffff<LF>Error status: 0<LF>Free file entries: 10<LF>SD card 0 detected, interface speed: 20.0MBytes/sec<LF>SD card longest block write time: 0.0ms<LF>MCU temperature: min 30.5, current 30.6, max 31.7<LF>Supply voltage: min 0.4, current 12.4, max 13.0, under voltage events: 0, over voltage events: 0<LF>Driver 0: standstil<Warning: Maximal number of bytes per line exceeded! Check the end-of-line settings or increase the limit in the advanced terminal settings.>I went ahead and reset my browser and mlike magic im back on the web interface.

-

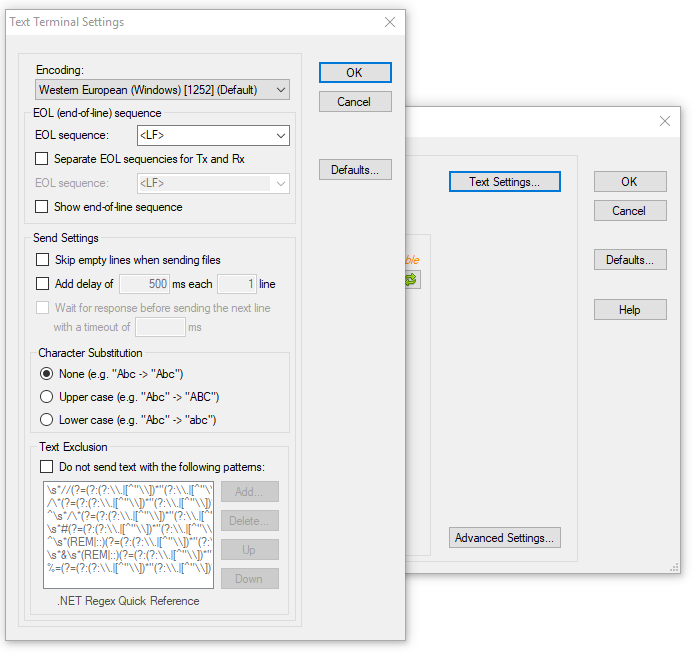

@sleepless please setup the terminal to display the messages properly:

Part of the M122 message is truncated.

-

sorry about that. thanks for the picture it really helps