Piezo drilling...

-

You must try an office paper puncher. It's really easier than drilling and you can get a neater hole.

-

The reason for turning the drill the wrong way is to avoid the bit tearing the brass.

I've drilled hundreds of piezo disks and it's something I really don't enjoy. It's messy, the dust is toxic and has a significant failure rate. I'm working on developing alternative products that will allow me to hopefully phase drilled disks out of my product line.

Idris

-

@moriquendi said in Piezo drilling...:

I'm working on developing alternative products that will allow me to hopefully phase drilled disks out of my product line.Like the orion?

Destroying the two piezo's isn't really a big problem. I had already decided to "downgrade" my titan aero to a simple titan + e3dv6, so using the orion is the next logical step. My only complaint is that I have to wait an additional week or two for shipping.

Destroying the two piezo's isn't really a big problem. I had already decided to "downgrade" my titan aero to a simple titan + e3dv6, so using the orion is the next logical step. My only complaint is that I have to wait an additional week or two for shipping.There's something about that Orion PCB I'm curious about: It appears that there are cutouts on it for 4x piezos, but only 2 are populated. Is there any interesting history there, or was it a case of "future planning" in case they might be needed?

-

@garyd9 Like the Orion in that it involves piezos soldered directly to the PCB. I have two products in the works. One is very simple, a replacement for plain and drilled piezos that plug into a Universal or Piezo20 PCB, eta ~1 week. The other is much more like the Orion but more adaptable to interesting hotends.

The first prototypes of the Orion had four piezos but only two were needed to generate the signal however the other apertures are needed to modify the stiffness of the PCB.

Idris

-

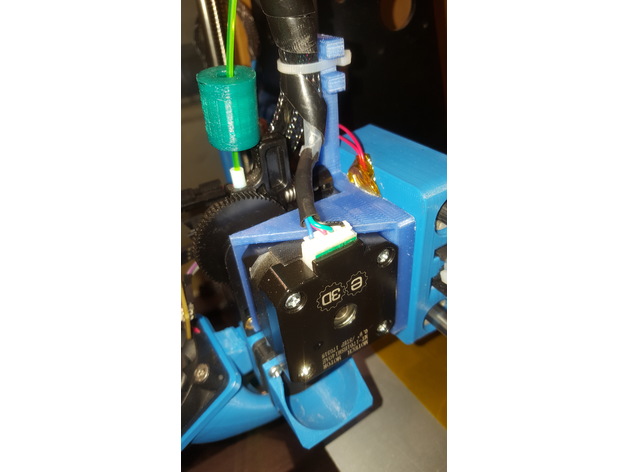

@garyd9 : if you have control over your xcarriage, then there is really no need to drill something whatsoever.

Just put the piezo between the extruder holder and the xcarriage like I have done here on my p3steel: -

@whosrdaddy said in Piezo drilling...:

@garyd9 : if you have control over your xcarriage, then there is really no need to drill something whatsoever.

Just put the piezo between the extruder holder and the xcarriage like I have done here on my p3steel:It's a delta. I've attached a render of what I'm hoping to end up with. (blower fan isn't in the image, and I still might change the fan duct. I need to wait until I get everything mounted so I can measure how big the orion module actually is.)

-

Ah I see, a delta is a better fit for under bed detection like Simon did with his delta: https://www.thingiverse.com/thing:2446460

-

@garyd9 said in Piezo drilling...:

I need to wait until I get everything mounted so I can measure how big the orion module actually is.

There are .step files of all parts on thingiverse.

Idris

-

@moriquendi said in Piezo drilling...:

@garyd9 said in Piezo drilling...:

I need to wait until I get everything mounted so I can measure how big the orion module actually is.

There are .step files of all parts on thingiverse.

Yes - I used them in the fusion360 rendering I posted. However, I'm not quite sure how tightly the parts fit together. I'm guessing that there has to be some amount of flex for the piezo to work, and the best place to measure that is in a working assembly.

Anyway, even if I were to get that perfect, I'm sure there's another area where my lack of fusion360 skill messed up "jointing" the parts together (or that one of the models I downloaded for the titan or v6 is off.)

The whole purpose in modeling all of it was to (learn how to use fusion 360 and) figure out how to "stretch" my part cooling fan. It looks like I'll need my part cooling fan duct to be 46mm lower when changing from a titan aero to a titan+e3dV6+orion (when mounted as seen in the image.)

-

@Moriquendi - a (not so random) suggestion for the "next revision" of the Orion mount:

I imagine that you spent a considerable effort designing the plastic for this so that threaded inserts could be used for the 4 screws that hold the mount/PCB/clamp sandwich together. However, I think that in most installations it would be impossible to adjust the screws in an installed unit.

Please consider an arrangement where the top (screw/groove mount) would have slots for 4 M3 nuts and the screws were inserted from the bottom (clamp.) The screws would obviously have to be the proper length to ensure that they don't pass above the top of the top mount.

If feasible, this would allow adjusting the tension from the bottom. I believe that in most "V6" heatsink installations, those 4 screws would be accessible from the bottom without any disassembly (though it might require a very short or "L" shaped screwdriver.)

Another thought might be to use threaded inserts in the top piece, but I've never seen an M3 heat-set insert that would be short enough. Perhaps M2x2.5 inserts in the top with M2 screws (instead of M3.) I don't know how that might impact the PCB, though.

I'm not sure if this is a feasible idea or not, but I thought it wouldn't hurt to toss out the suggestion.

Take care

Gary -

There's nothing preventing you from modifying the top piece. I think you are correct that the current groovemount top piece is too thin for M3 inserts but I'm not sure that smaller screws are the answer. I find M2 screws very fiddly and awkward to use, prone to rounding heads etc. If you're going to tackle it, I would increase the thickness of the top piece instead of using smaller screws.

I do see your point that the screws are inaccessible or awkward to access once assembled however I think that some of them would still be awkward to access from below. Once adjusted they shouldn't need to be changed so I don't see it as a significant problem.

Idris