@wilriker FYI, If you have a plastic spool holder, it will transfer static charges via the filament onto the ungrounded) extruder motor (2 users recently have been hit by this problem)

Best posts made by whosrdaddy

-

RE: Grounding!posted in Duet Hardware and wiring

-

RE: RepRapFirmware 2.0 with RTOS in developmentposted in Firmware installation

Completed 2 5 hour prints on 2.0 alpha without any issues, amazing stuff David!.

2 (minor) problems I found so far:

- sometimes the ESP8266 would not boot a power up (blue led won't light up) ( a power cycle solves this).

- DWC Disconnects at the end of an upload.

for reference:

Firmware Name: RepRapFirmware for Duet 2 WiFi/Ethernet

Firmware Electronics: Duet WiFi 1.02 or later

Firmware Version: 2.0(RTOS)alpha1 (2018-04-05b2)

WiFi Server Version: 1.21

Web Interface Version: 1.21.1-b1Here is the last completed print on 2.0 alpha

-

RE: gcode to run at power upposted in Duet Hardware and wiring

I would create a macro and call it at the end of

config.gwithM98. -

RE: desperate, about to give upposted in Firmware installation

@bearer no you are on the right track, motor currents are way too low.

@printingmark try setting 1000ma for the xyz motors and 1300ma for the extruder motor. -

RE: Intergrating a precision piezo in Duet-wifiposted in Duet Hardware and wiring

The reason that there many pins is that you can easily connect multiple piezo disks.

For example, I have 4 disks in my setup (2 x 2 in parallel, 1 for pickup, 1 for noise canceling)

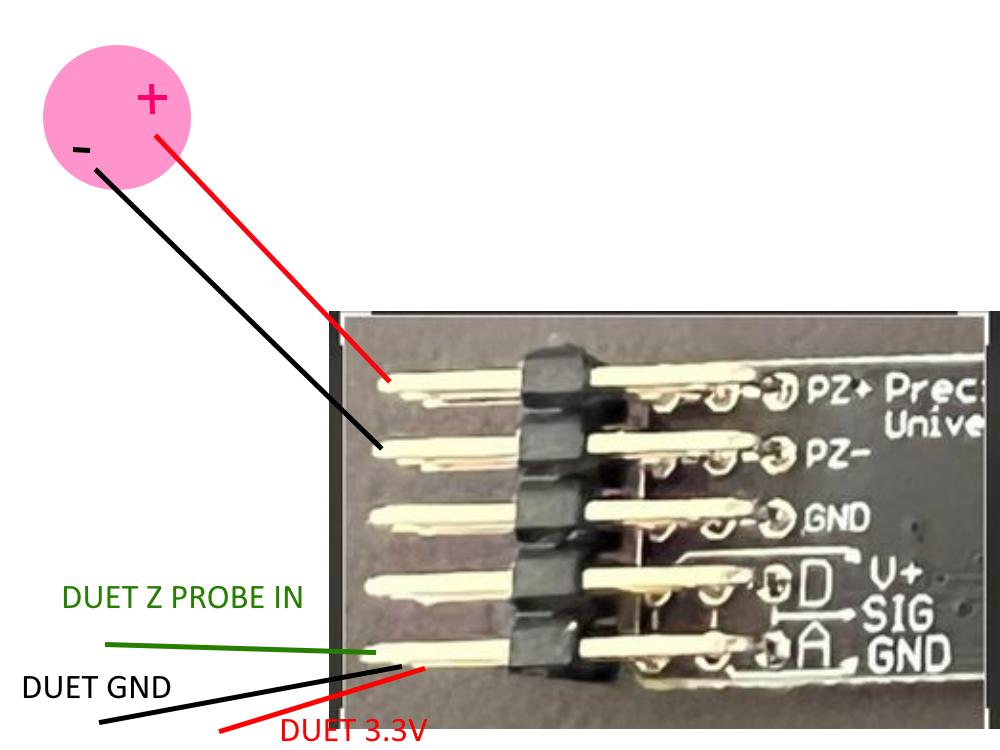

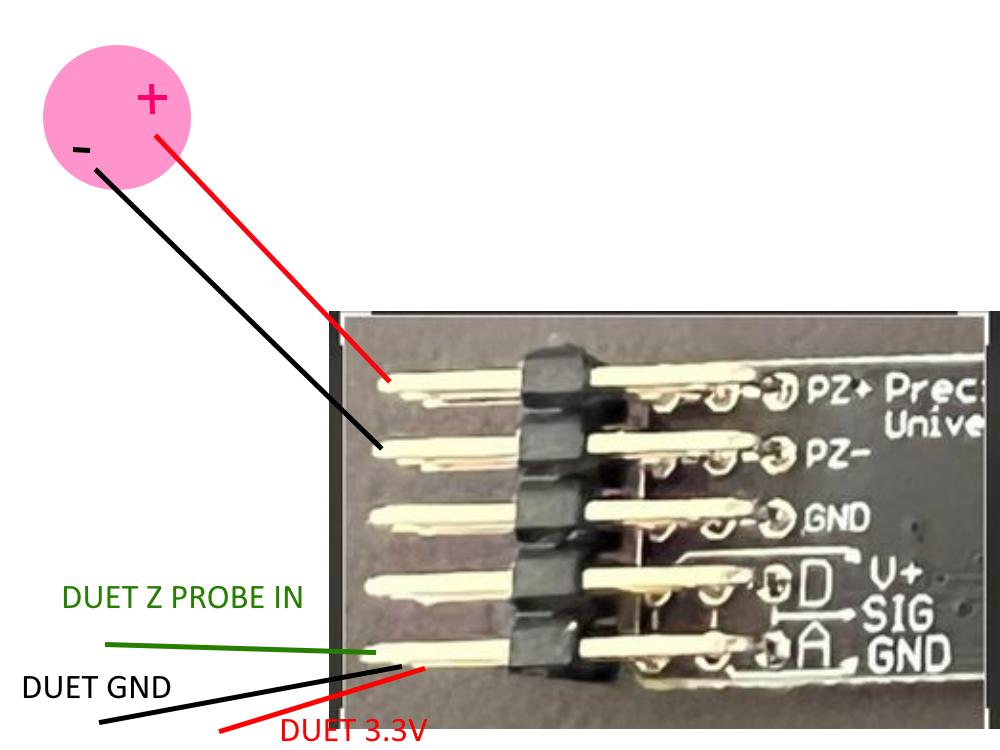

The confusing part is that the piezo's connect horizontally but the connection towards the Duet is a vertical connectionThis is the order - I am using the first image as a reference here, second image inverts the pcb.

As you see on the silkscreen the 2 bottom vertical stacks are the same:

Top pin connects to Duet Z Probe in

Middle pin connects to Duet Ground

Bottom pin connects to Duet 3.3VThe pins to the top are 3 horizontal pairs to connect piezo disks to, make sure you respect the polarity (use a multimeter if you are not sure) otherwise the board will perform bad

The pins in the middle are just ground and are generally not used.

here is an attempt explaining it with Paint:

Hope this helps

-

RE: Math and Variables in gcodeposted in General Discussion

Here is the doc how to configure indepent Z motors:

https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_ -

RE: Limited service from me during 3D Meetup Swedenposted in General Discussion

Found a youtube video from this year, the Duet stand can be seen around 4:30 minutes in the video.

It seems that they have a Zatsit printer on display

-

RE: Extruder Max Speed Stuck at 1.33mm/sposted in General Discussion

Pro Tip:

if you put

M92BEFOREM350, you define the values for x16 andM350will do the correct math if you change from x16 to a higher stepping mode... -

RE: Extruder stopped workingposted in General Discussion

Your extruder driver could be blown, try remapping the extruder to the E1 and see if that fixes your problem.

Also make sure that the cable to the extruder is intact (put a motor with a different cable on the board) -

RE: DuetWifi-error: filename too longposted in General Discussion

Seems like the duet is getting ocsp requests (certificate checks), I guess you are using a Mac?

This is normal as the duet is the internet connection for the computer when the duet is in AP mode.

You can turn it off if you want, look here for more information.

Latest posts made by whosrdaddy

-

RE: Intergrating a precision piezo in Duet-wifiposted in Duet Hardware and wiring

The piezo board should receive power from the Duet.

you are using the Z probe in connector on the Duet right? -

RE: Intergrating a precision piezo in Duet-wifiposted in Duet Hardware and wiring

These are my relevant lines in config.g, I use the piezo's as underbed Z-probe:

M574 Z1 S2 ; Set endstops controlled by probe M558 P8 X0 Y0 Z1 H6 I1 R0.3 F900 T9000 A6 S0.015 ; Piezo V2 probe used for homing Z axis, dive height 2cm, probe speed 600mm/min, travel speed 150mm/s G31 P500 X0 Y0 Z-0.14 ; Set Z probe trigger value, offset and trigger height -

RE: Intergrating a precision piezo in Duet-wifiposted in Duet Hardware and wiring

@mendelevium What board do you have? I can give you my setup if you want (Duet 2 Wifi here)

-

RE: Intergrating a precision piezo in Duet-wifiposted in Duet Hardware and wiring

The reason that there many pins is that you can easily connect multiple piezo disks.

For example, I have 4 disks in my setup (2 x 2 in parallel, 1 for pickup, 1 for noise canceling)

The confusing part is that the piezo's connect horizontally but the connection towards the Duet is a vertical connectionThis is the order - I am using the first image as a reference here, second image inverts the pcb.

As you see on the silkscreen the 2 bottom vertical stacks are the same:

Top pin connects to Duet Z Probe in

Middle pin connects to Duet Ground

Bottom pin connects to Duet 3.3VThe pins to the top are 3 horizontal pairs to connect piezo disks to, make sure you respect the polarity (use a multimeter if you are not sure) otherwise the board will perform bad

The pins in the middle are just ground and are generally not used.

here is an attempt explaining it with Paint:

Hope this helps

-

RE: Fast Response Part cooling fanposted in Tuning and tweaking

Yes it is an inherent side effect.

There are some options though.

a) let the heater blow constantly air at the printed layer (not easy do this consistent), I believe I saw one concept here in the forums but can't find it atm

b) berd air (this works but to get it 100% dialed in is not easy as you really need to aim the air just under the nozzle and make sure you do not cool other parts of the print as this will lead to thermal stress)

c) use support material (the better option), if you have 2 independent heads or a toolchanger you even have the option to print your support in another material (like pve or pla)

I print all my ABS prints with full supports and while it is a bit tedious to remove the support material, it simply delivers the best prints. -

RE: Strange layer offset on coreXYposted in Firmware installation

This is a mechanical problem, not an electronics problem.

Can we see pictures of your belt setup. I guess one or more belts paths are not perpendicular to X or Y motion... -

RE: Any advice printing tpu ?posted in General Discussion

I do not have glass but I use bed temps around 70°C, this is on a PEI like material.

Much depends on the hardness of the TPU, as a general rule of thumb the harder, the more temp it needs.

Don't forget to disable retractions (but I guess you already know that) -

RE: repeat a part of a macroposted in Using Duet Controllers

@cosmowave As I understand it, is that if the user presses cancel the macro is aborted, so just make an infinite loop and put

M291in it. -

RE: Infinite U-axis, but linear motion?posted in General Discussion

Treat it as a normal linear axis with a fixed length (if you unfold the ellipse, you will get a line of a certain length), and home it at a certain point on the axis.