Questions printing PETG

-

I am getting some strange shrinkage with petg I can't seem to figure out. The part starts off at a normal width then shrinks inward for a bit before it it starts tapering out. It only happens on external perimeters. all of the internal perimeters are perfect. I tried lowering my bed temp thinking the radiant heat was causing the problem but that made no difference. also if go to low I loose adhesion. I am open to any ideas. I am currently printing at 240deg for the hotend and 80deg for the bed. Printing at 40mms internal and 30mms external. No fan (seems to make my prints brittle) I print on a pei sheet on glass. Bed is perfectly level. Oh also I can print ABS and PLA perfectly. I only see this issue with petg of any brand.

-

Try printing a full height skirt around a smaller object to see if that has an effect? Have you got an enclosure on your machine?

-

@doctrucker i will give that a go. And yes I do use an enclosure. It's a fully enclosed corexy

-

Nice. Had one at last employment but need to build up business before I can justify one now. If you've an enclosure the skirt is a long shot, but keep it as close to the part as you can.

-

i've got a print running right now that is showing the same issue. Actually the draft shield seems to be bowing in. I can't see the rest of the print yet. It has to be a temp or speed issue. Someone on reddit suggested either cutting my bed temp down and using glue stick or trying some low fan speeds. They think the lower part of the print is retaining too much heat.

-

There are a couple of things that may be causing this

- you are printing the first layer too far from the build plate.

What happens especially if under extruding this void of material will follow the whole print process until it finally gets to a point where there is enough filament for that layer - you are under extruding

Just a couple of things to play with. Petg is wonderful material just takes a bit of get use to

- you are printing the first layer too far from the build plate.

-

It looks like elephant footing to me. Reduce bed temperature, but not so much the print comes off, and print a sacrificial object a few cm away from the main print to give those layers a little extra time to cool before the nozzle comes back and dumps more hot plastic on them.

-

@mrehorstdmd you are correct! It was a temperature issue. Too much heat was staying in the print and it was basically printing layers on top of layers that hadn't become solid. Usually this would show curled corners but there were no corners in this model. For small prints I usually print multiples for that reason. I assumed the size of the print had enough layer time to cool. I dropped the bed temp to 75 and ran just enough fan to not hurt the strength of the print. On a side note that print that did warp is crazy strong. I ran it over out of curiosity and it looks like I just pulled it off the printer lol.

-

It just goes to show that even a broken clock can be right once in a while...

-

I print PETG with 60 deg. bed temp on PEI and it sticks all to well.

-

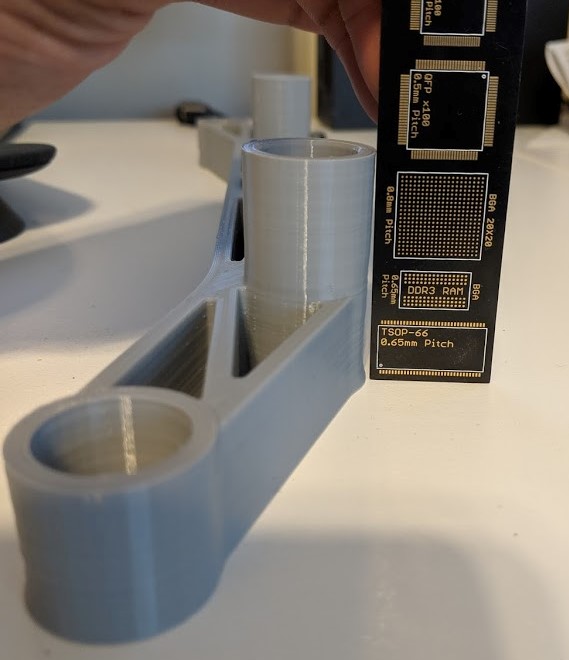

I print various brackets that have no real fine detail but need to be tough and so use PETG using 240 deg nozzle temp, 60 deg bed temp (blue tape) and zero fan. 3 walls and 20% gyroid infill and they come out just fine. I reinforce some regions in the part with 90% infill as you can see here