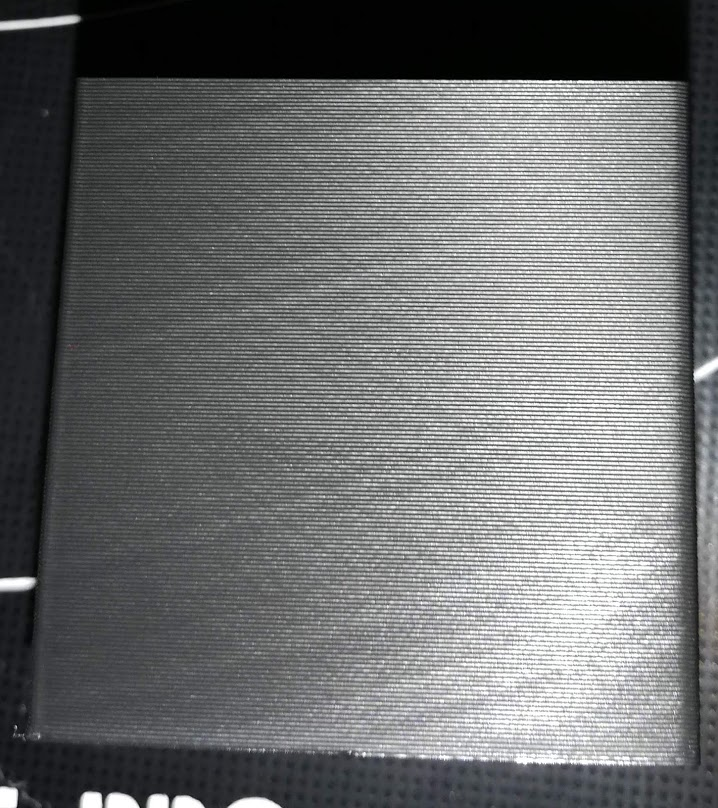

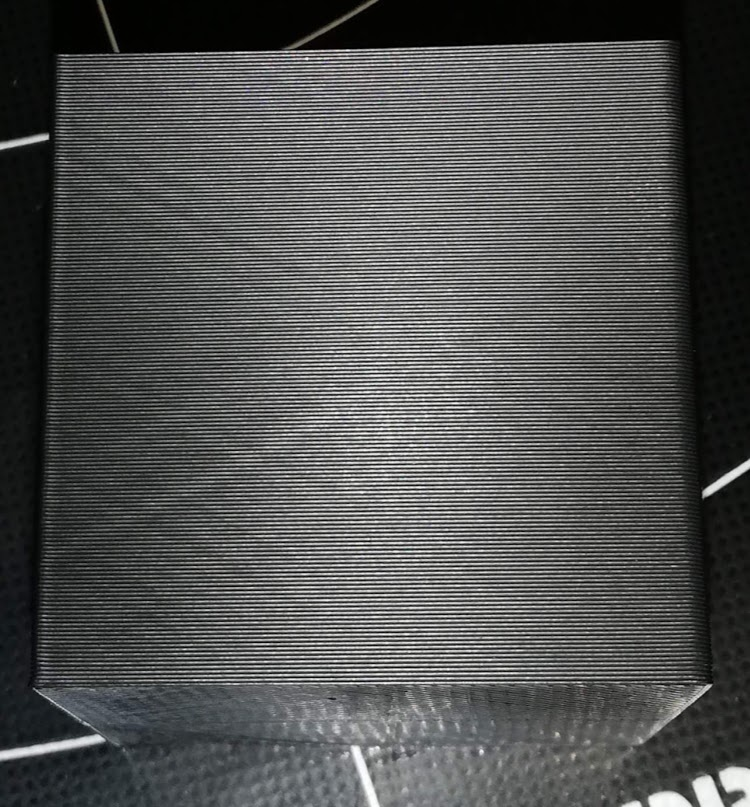

Strange salmon skin - Moire effect on my Delta

-

-

Config below

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Tue Feb 26 2019 21:31:01 GMT+0000 (Greenwich Mean Time); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves; Delta Settings

M665 L440.000 R227 H456.0 B185.0 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 A0.00 B0.00 ; Put your endstop adjustments here, or let auto calibration find them; Network

M550 P"Anycubic Predator" ; Set machine name

M551 P"" ; Set password

M552 S1 ; Enable network and acquire dynamic address via DHCP

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S0 ; Drive 0 (X) goes forwards

M569 P1 S0 ; Drive 1 (Y) goes forwards

M569 P2 S0 ; Drive 2 (Z) goes forwards

M569 P3 S0 ; Drive 3 (Extruder) goes forwardsM906 X1000.00 Y1000.00 Z1000.00 E1000.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeoutM350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80.00 Y80.00 Z80.00 E415 ; Set steps per mm

M566 X1000 Y1000 Z1000 E1000 ; Set maximum instantaneous speed changes (mm/min)

M201 X1100.00 Y1100.00 Z1100.00 E1100.00 ; Set accelerations (mm/s^2)

M203 X15000.00 Y15000.00 Z12000.00 E3600.00 ; Set maximum speeds (mm/min)+ 1000 + M203 X15000.00 Y15000.00 Z15000.00 E5800.00

M566 X1200.00 Y1200.00 Z1200.00 E1500.00 ; Set maximum instantaneous speed changes (mm/min) +M566 X1500.00 Y1500.00 Z1500.00 E1200.00; Retraction

;M207 S4.0 F5000 R-0.025 T2500 Z0.5 ; Firmware retraction; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; Set active high endstops; Z-Probe

M558 P4 H5 F120 T6000 ; Set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z16.1 ; Set Z probe trigger value, offset and trigger height

M557 R115 S20 ; Define mesh grid

G29 S1 ; Load the heightmap; Heaters

;M307 H0 A137.8 C533.3 D1.5 V24.3 B0 ; Disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4300 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4300 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 240C; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

T0 ; Set T0 as default

; Automatic saving after power loss is not enabled; Custom settings are not configured

M572 D0 S0.1 ; Pressure Advance

;M591 D0 P2 C4 S1 ; Activate filament sensor

M404 N1.75 ; Set for print monitor

;M592 D0 A0.07772 B-0.00029 ; Nonlinear extrusion. Set parameters for extruder drive 0; Miscellaneous

M501 ; Load saved parameters from non-volatile memory -

-

What layer height are you printing at? Try making the layer height an exact number of full steps, if you are not already, for example 0.2mm.

What is the rated current of the tower motors and the extruder motor?

-

@dc42 I've tried all the 'magic' numbers, doesn't seem to make any difference

0.0809, 0.1618, or 0.3236

0.1294, 0.2589, 0.3883

0.2 even 0.2589No idea what the rated current is, the motors have no markings on them

-

I would guess standard 1.5A

-

If you change the extrusion width (or, if it is a vase-mode print, you could just change the extrusion factor in DWC) while keeping the layer height constant, does the angle of the banding change? If so, that suggests an extruder issue.

-

-

What is the vertical spacing between the diagonal bands?

-

-

I was wondering whether it was related to the tooth pitch on the belts, which I presume is 2mm.

-

@dc42 If that was the case, would that indicate an issue with the belts or the toothed pulley?

-

@totalitarian said in Strange salmon skin - Moire effect on my Delta:

@dc42 If that was the case, would that indicate an issue with the belts or the toothed pulley?

Yes, or perhaps with the toothed side of the belts running over non-toothed idlers. But I would expect the vertical pitch of the banding to be 2mm, not 4mm

-

Such a shame as otherwise it is a very well put together machine.

-

@totalitarian said in Strange salmon skin - Moire effect on my Delta:

I would guess standard 1.5A

measure the resistance of a phase. that will give some indication as to what kind of motors they are.

-

It looks like typical delta waves on your printed parts. Bent diagonal patterns on flat surfaces. That's a sign that something is not perfect with the linear motion. It could be the pulleys, idler, linear bearings, ...

The bend in your patterns is not very sharp, the predator is a very large machine. A smaller machine will get sharper bends. If you move the model to the edge of the platform the angles should change, and the patterns will get tighter or more spread out depending on what/which towers is the cause.When it is motor/driver related you usually get a tight, highly repetitive patterns. If you turn off microstepping it will show up very clearly. That's not a suggestion to solve your problem, but a fun experiment to see what it looks like

-

@bondus Thanks, i'll certainly give that a try. Do you not suspect the rods at all?

-

@totalitarian, I don't know how play in the arms looks like in prints. But I suspect it would not leave nice patterns. Who knows, deltas are complex machines.

It's easy to check for play of the ball joints, just wiggle the arms, any click-clock sounds are bad. Rumour says that if you have play in those small joints you can gently squeeze them on the edge in a vice or with some pliers to increase the preload.