I love strange kinematics, and when I discovered the parallel scara I had to build one.

The Duet did not have support for this kinematics in stock firmware but @JoergS5 had an almost complete implementation that we have developed further. The firmware works very good now.

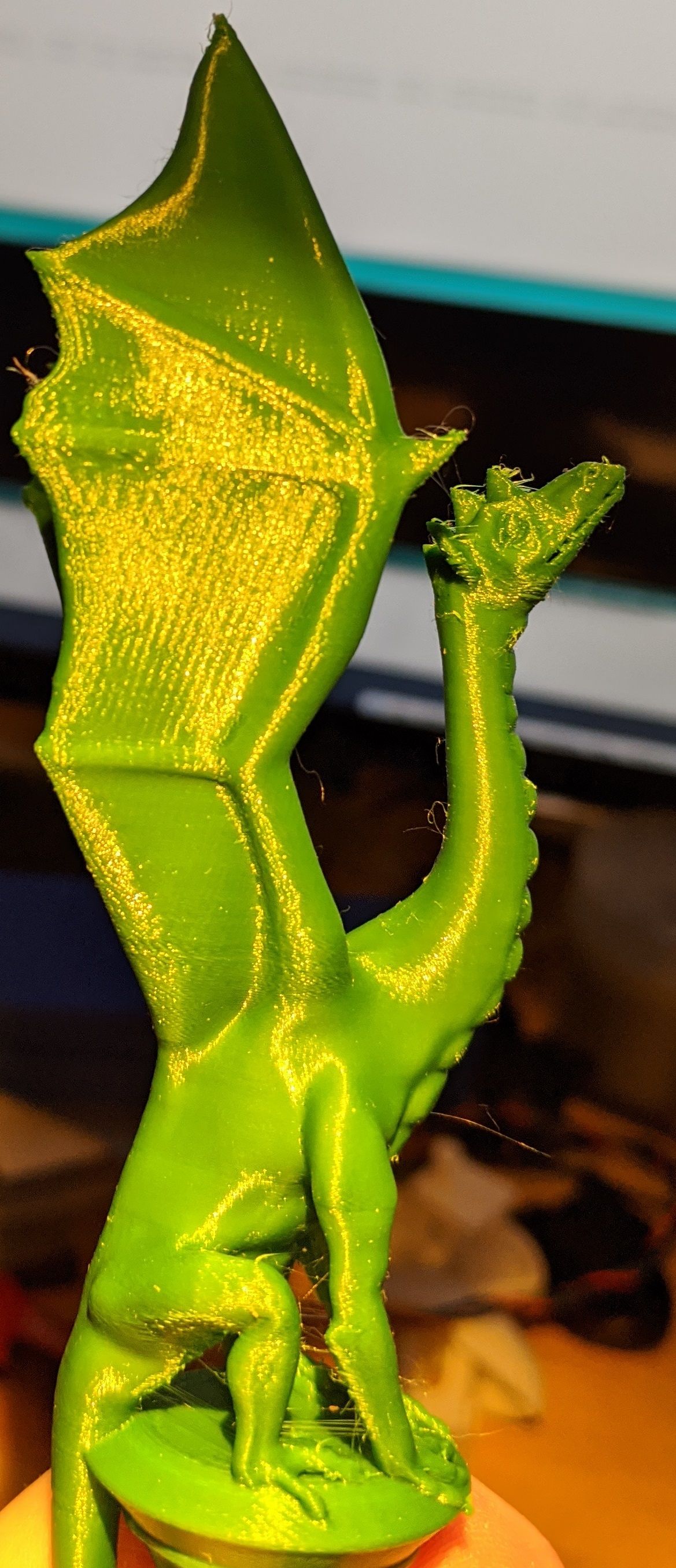

The machine is made mostly of printed parts and items you can easily get hold of, and a hacksaw and hand drill. No machined parts. The precision is not the best but it still works pretty good (just a nightmare to calibrate). It's still a prototype/proof of concept so it does not look very good and many parts are stuff I had laying around.

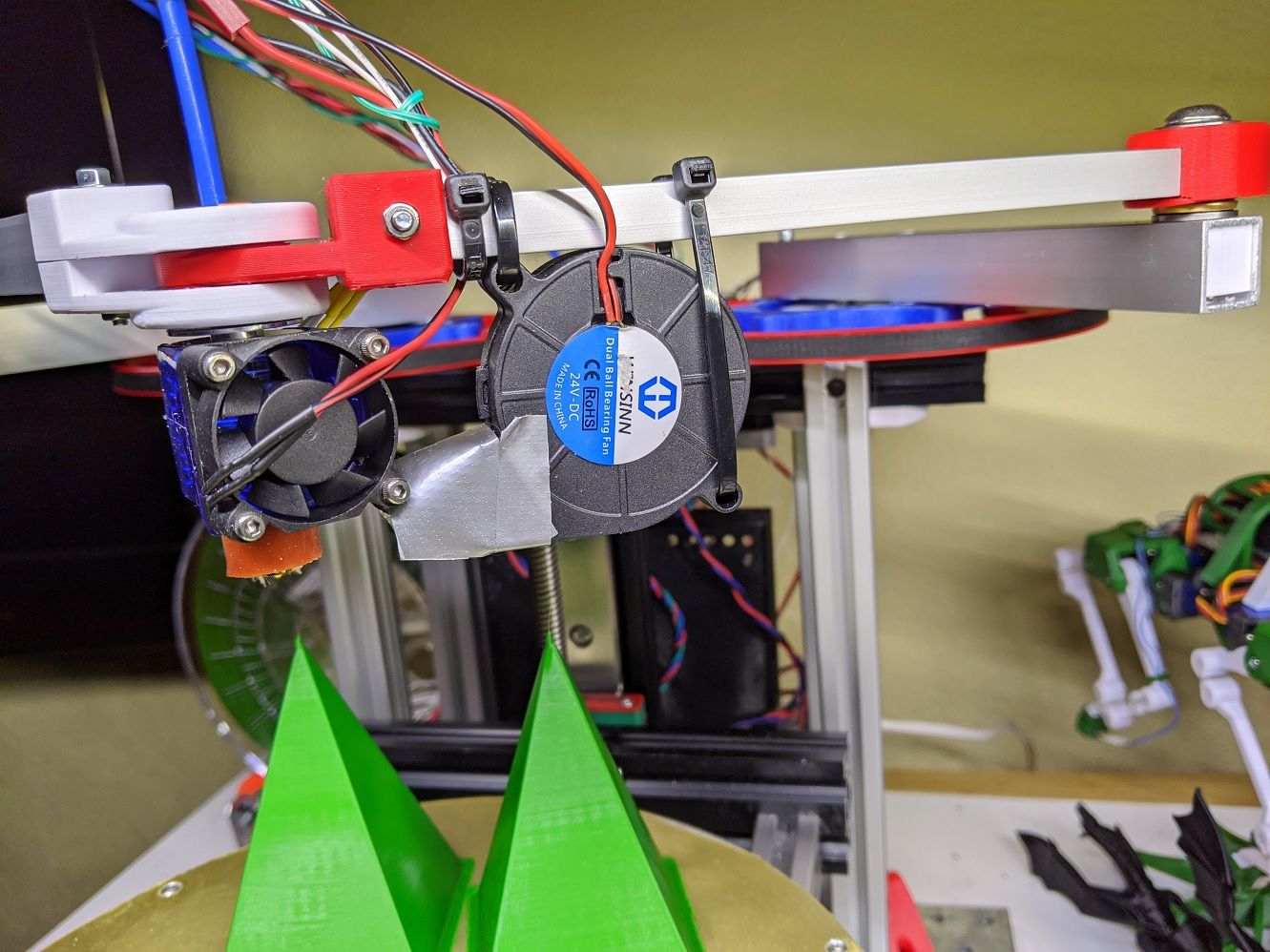

The body rides on 3 12mm rods with LML12UU-like bearings, and has one leadscrew. The inner joints have two 6806 bearings per arm. The elbows use two 8mm thrust bearings each, preloaded with an m8 rod, a crude solution that works very well. That joint is very stiff. The hotend joint has two 6704 (20x27x4) very thin and light bearings inside. Lots of bearings.

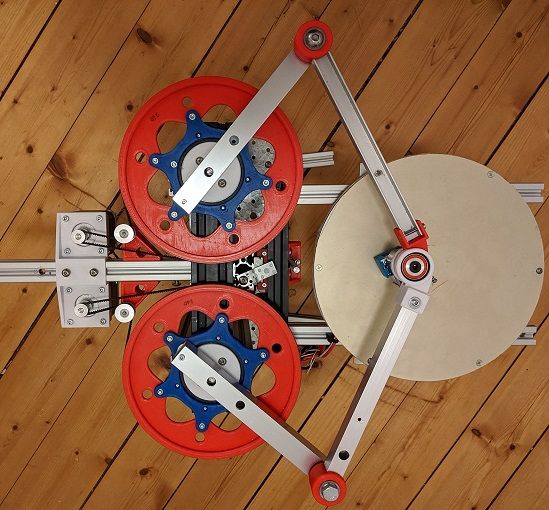

The motors driving the arms are 48mm 0.9degree NEMA 17 with a 20t pulley leading to a 200t printed pulley. This gives a gearing of 1:10 which is very much on the low side. 1:30 would be far better. But upping the microstepping to 64 or even 256 saves the situation. A problem with 256 microstepping is that the Maestro starts to get stepping rate problem over 400mm/s.

Using a normal gearbox is not possible due to their backlash. A machine like this needs a gearbox with almost no play, like a harmonic drive. A belt gearbox works pretty good but the gearing is limited due to size.

With the 180 and 216 mm long arms the printing area is approximately 300x200mm. The actual print area is actually half-circleish shaped and quite a lot bigger.

The printer can move at blazing speeds and accelerations without any drama and shaking. The kinematics is similar to a polar delta but just 2 axis instead of 3. Currently it has a fair amount of ghosting at high speed/acceleration, but prints very good at a more reasonable 60mm/s and 2000 acceleration. I think the ghosting is due to a far too wobbly tower, or possibly flex in the belts. I have got some metal clamps for the 12mm rods and some more 3060 extrusion in the mail, it might help.

I made a little video showing it moving fast https://www.youtube.com/watch?v=MW8HApFoy38.

Here is an earlier version doing the first reasonably successful benchy print.

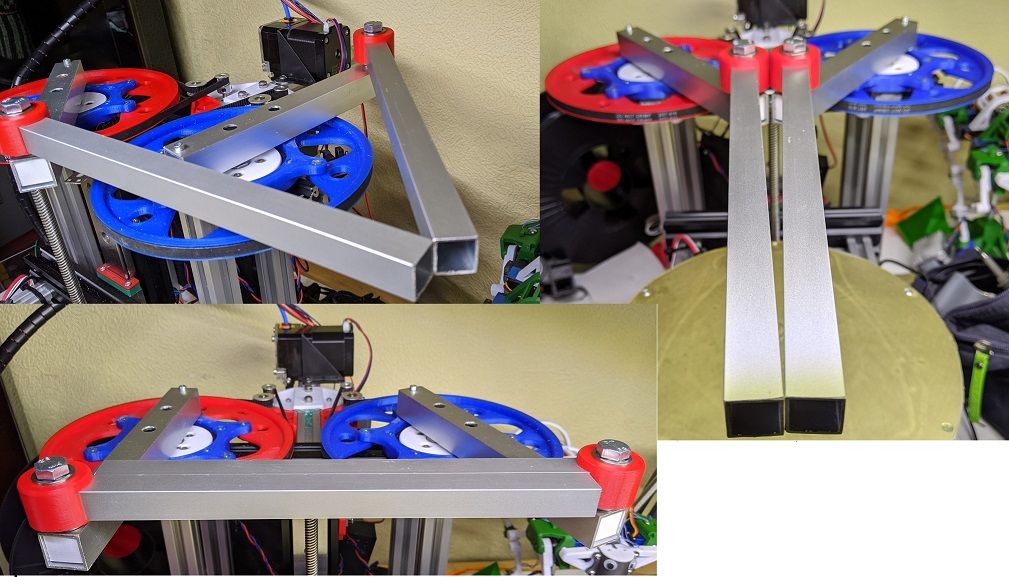

Those arms were made of small U-beam and far too wobbly, changing to bigger 20 mm square beams made a massive difference.

The very first little prototype to get a feel for the kinematics, a very useful little toy

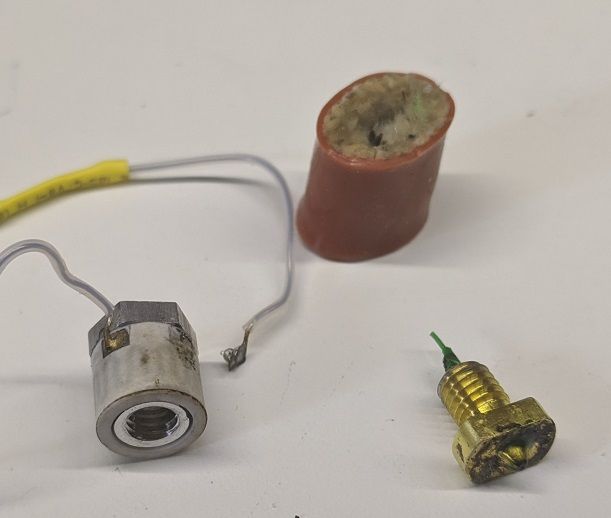

They were amazing, heated up in 20s and could handle high flows. The RRF PID tuning used to warn that "ultimate temperature" was unsafe when auto tuning

They were amazing, heated up in 20s and could handle high flows. The RRF PID tuning used to warn that "ultimate temperature" was unsafe when auto tuning