Driver temperature still ok?

-

@nxt-1 said in Driver temperature still ok?:

I have the motors for my delta running at 2100mA. When I touch the relevant driver chips most of them are to hot to keep my finger on. Am I correct in assuming that as long as I do not get 'driver over temp' warnings, there is absolutely no problem?

I am actively cooling the underside of the board with this mount from Thingverse. There is very ample airflow with the 40x20mm Noctua I got on there.

They are OK if you are not getting over temperature warnings. The over temperature warning kicks in when the chip reach about 100C. The over temperature shutdown kicks in at about 130C.

-

@dc42 said in Driver temperature still ok?:

@nxt-1 said in Driver temperature still ok?:

I have the motors for my delta running at 2100mA. When I touch the relevant driver chips most of them are to hot to keep my finger on. Am I correct in assuming that as long as I do not get 'driver over temp' warnings, there is absolutely no problem?

I am actively cooling the underside of the board with this mount from Thingverse. There is very ample airflow with the 40x20mm Noctua I got on there.

They are OK if you are not getting over temperature warnings. The over temperature warning kicks in when the chip reach about 100C. The over temperature shutdown kicks in at about 130C.

Thanks for the confirmation

-

@bearer said in Driver temperature still ok?:

I'd ask myself if I really needed 2.1A current, presumably this is a fairly large machine with a heavy effector?

As with all electronics life span and temerature are connected, so if you can't touch it I'm guessing its 60C or more, that usually enough to derate the MTBF rating considerably.

Both assumptions are correct. The extrusions are 1,5m tall and the effector carrier of course the hotend, but a Bondtech BMG as well. Some more info about the build can be found on the Reprap forums

-

Its worth adding the following, the over temperature and shutdown temperatures are typical 100 and 130C, but are also spec'ed +/-20C without any real data on accuracy. And the junction temperature be higher than the epoxy encapsulation.

So while the chip has protection to prevent immediate damage and catastrophic failure I would most certainly consider adding heatsinks to the bottom of the board, where the thermal vias are and increasing the airflow. The thermal dissipation should be around 2W pr chip, that should be doable to keep a lot cooler without noise to ensure a long and healthy life for the board.

-

@bearer said in Driver temperature still ok?:

Its worth adding the following, the over temperature and shutdown temperatures are typical 100 and 130C, but are also spec'ed +/-20C without any real data on accuracy. And the junction temperature be higher than the epoxy encapsulation.

So while the chip has protection to prevent immediate damage and catastrophic failure I would most certainly consider adding heatsinks to the bottom of the board, where the thermal vias are and increasing the airflow. The thermal dissipation should be around 2W pr chip, that should be doable to keep a lot cooler without noise to ensure a long and healthy life for the board.

So what you suggest is to add something like a longish rectangular heatsink underneath were the drivers are located, separated with a sticky thermal pad of course?

@dc42 What do you think? -

there was a similar thread about this

https://forum.duet3d.com/topic/8451/found-a-heatsink -

But yeah, I think I put some 15x15x15mm on the stepper drivers, and bigger/smaller for cpu/ethernet/3.3v regulator because compared to the cost of the board the heatsinks are nothing and the cooler it runs the longer it will last.

-

I conclude this topic as heatsinks are not required, as stated by DC and thermal testing they did. It might however improve temperatures if applied correctly.

-

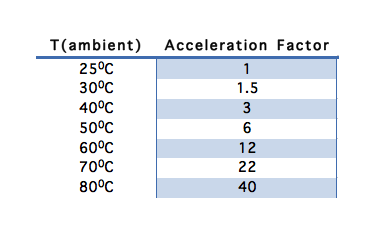

Look up MTBF and temperature; in general MTBF is rated for 25C; as the temperature increase you accelerate the aging of the components. Electronics that stay cool live longer, and cooling is dirt cheap, but do you need it? Maybe not.

One of the sources has that nice table, you'll find plenty of resources saying pretty much the same thing, numbers may vary a little, but the trend is clear.

-

The problem with heatsinks is that they need to be properly applied in order for them to actually sink heat, otherwise they act as insulators.

The board is designed to use the copper of the ground plane as a heat sink and there should be sufficient airflow going across both sides of the board.

The design of the enclosure can matter just as much as the fans used, etc. Consider how a high end network switch is cooled. It's a sealed rectangular box. Air inlet holes on one end, and exhaust fans on the other pulling cool air across the board and pushing the heated air out of the chassis.

-

Its pretty modest TDP looking at the datasheet

But reading, ample airflow, and, too hot to touch, I can't help think that there is room for improvement. We can't really get away from the fact that cooler will always be better. But I'm done now, people can do whatever they like.

-

@bearer I don't disagree, just caution that heat sinks need to have good contact to actually sink heat otherwise they can do more harm than good.