upgraded to smart extruder ,getting parts that are off size

-

ok do im still chasing issues with my delta and im sure its due to the auto calibration not being able or over correcting my setup.

parts are not sized correctly and if i am interpreting it correctly the printer is moving in a concave arc (higher in the middle)

the bed level compensation seems to show this too. any ideas how i fix this?

where do i start?

printer is a rostock mk2 with injection molded cheap skates, ball cup arms, smart effector, e3d volcano , maker 713 metal effector plate for smart extruder.

Firmware Name: RepRapFirmware for Duet 2 WiFi/Ethernet

Firmware Electronics: Duet WiFi 1.02 or later

Firmware Version: 2.03beta3 (2019-03-25b6)

WiFi Server Version: 1.23

Web Interface Version: 1.22.6everything is tight and seems to be working ok its printing well just not to size

thanks

Raptor

-

What result do you get when you run G32 a number of times? does it converget o a "small" error (min generally gets to <0.02. for more detail see:

https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printer#Section_Auto_calibration

-

The pattern you are getting suggests to me the either the rod length (M665 L parameter) or tower steps/mm (M92 X,Y,Z parameters) are configured incorrectly. The M665 L parameter must be the rod length measured between the centres of rotation of the bearings. You can check the tower steps/mm value by commanding Z movements and measuring whether the actual movement is equal to the commanded movement.

Can you confirm that you are using the PCB carriage adapters to connect the top ends of the rods to the carriages?

Photos of your printer may help.

-

thanks for the help.

im using the ball arms from seemecnc, they are injection molded and i just checked they are all the same length. i measured them a few different ways and got a number of 291.5mm but its hard to measure the center of a circle and i don't have calibers long enough. seemecnc think the arms are 291.06mm

here is a pic of the printer. i am not using the pcb adapters.

-

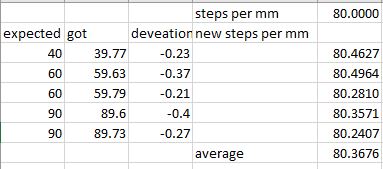

That look OK then. Have you verified the tower steps/mm?

-

yes, here is what i found.

i am updating this value and running the test again.

the printer was printing within the expected size range with the Rambo board, and when i disabled the probe and probe manually with a paper the error seems to go away. the issue seems to be with the probe trigger. it is much better with the smart effector vs the bltouch i removed before.

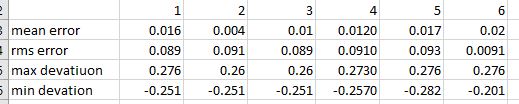

i have also run the bed probe 6 times and this is what i got:

-

I don't normally recommend using 7-factor calibration, but I'm wondering whether it might help in this case, because the height map definitely shows the symptoms of the relationship between rod length and steps/mm being wrong.

-

so i changed to 7 factor with 16 points.

this is what it wrote to the override file

M665 L286.069:286.069:286.069 R133.041 H321.956 B134.0 X0.220 Y0.287 Z0.000

M666 X0.965 Y-0.085 Z-0.880 A0.00 B0.00considering the arms are supposed to be 291.06 and this is what seemecnc use on their printers with duets, any ideas what could be causing this?

-

@raptor your setup in very similar to SeeMeCNC setups using those arms so i think you are on the right track. Can i ask you to try something (indulge my curiosity) what happens when you use 6 factor (with the 291.. arm length) and run a number of G32 commands in succession. what results do you get?

-

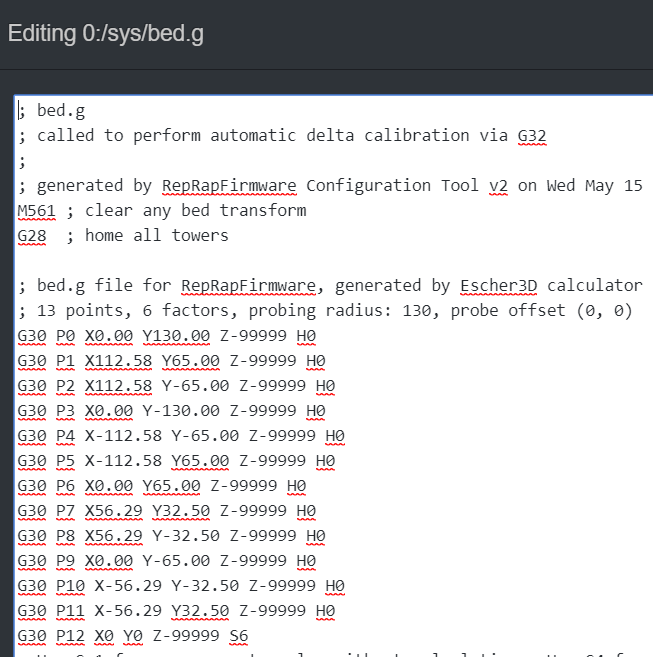

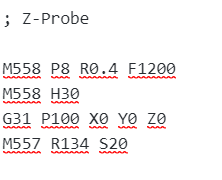

sure! what data do you need? i posted the results above before i changed the arm length. here are the images

-

@raptor

Thats mesh bed compensation - which is useful if your bed is not flat, but should be used after delta calibration has arrived at the best possible calibration for your printer.So (for now) ignore the bed mesh and confirm that the delta calibration is as good as it can be: In the console send:

G29 S2

That will remove the mesh compensation height map. Then G32, that will probe the bed in accordance with the points in bed.g - please use 6 factor for this at this point.

You will get a result in the console saying what (if any) improvement there is in how the 6 factor calibration has converged. Run G32 a number more times (say 5?) and see if those figures get better. Let use know how you get on. Make sure you save (M500, assuming you are using config-override.g) the final set of calibration numbers.

-

@t3p3tony ooops sorry! totally missunderstood. i'll run g32 a few times and report back

-

here is what the log said: 6 factor original steps per mm and original arm length.

this was the final override

M665 L291.500:291.500:291.500 R135.003 H323.062 B134.0 X0.285 Y0.293 Z0.000

M666 X0.941 Y0.019 Z-0.960 A0.00 B0.00please let me know how to proceed

G32

Calibrated 6 factors using 16 points, deviation before 0.117 after 0.115G32

Calibrated 6 factors using 16 points, deviation before 0.120 after 0.119G32

Calibrated 6 factors using 16 points, deviation before 0.119 after 0.117G32

Calibrated 6 factors using 16 points, deviation before 0.128 after 0.123G32

Calibrated 6 factors using 16 points, deviation before 0.127 after 0.124G32

Calibrated 6 factors using 16 points, deviation before 0.130 after 0.127G32

Calibrated 6 factors using 16 points, deviation before 0.172 after 0.120G32

Calibrated 6 factors using 16 points, deviation before 4.763 after 0.136G32

Calibrated 6 factors using 16 points, deviation before 20.182 after 0.381 -

@raptor said in upgraded to smart extruder ,getting parts that are off size:

so i changed to 7 factor with 16 points.

this is what it wrote to the override file

M665 L286.069:286.069:286.069 R133.041 H321.956 B134.0 X0.220 Y0.287 Z0.000

M666 X0.965 Y-0.085 Z-0.880 A0.00 B0.00considering the arms are supposed to be 291.06 and this is what seemecnc use on their printers with duets, any ideas what could be causing this?

In what way are the parts off size: too large or too small? If they were too small then reducing the effective arm length (as 7 factor calibration has done) will have made them larger, as well as reducing the deviation.

-

@dc42 sorry I should have mentioned that the parts are too small. I'll reduce the arm length like the 7 factor did.

-

@raptor said in upgraded to smart extruder ,getting parts that are off size:

G32

Calibrated 6 factors using 16 points, deviation before 4.763 after 0.136

G32

Calibrated 6 factors using 16 points, deviation before 20.182 after 0.381What is going on here, are there the first or the last results? If first then you can see a huger improvement for the first 3 times G32 is run and then it stays pretty stable after that.

-

those are the first results.

i spend some time tweaking the probe sensitiviy, i noticed that the effector was tilting over on a probe, so increasing the sensitivity to 15 seems to have helped it. the parts are more in size now. i ran the 7 factor and it decided the arms were all the same length but needed to be as follows:

M665 L293.761:293.761:293.761 R136.460 H323.451 B134.0 X0.096 Y0.131 Z0.000

M666 X0.978 Y0.004 Z-0.983 A0.00 B0.00sizing seems to be improved now

-

Spoke too soon sizing is still off.

-

@raptor said in upgraded to smart extruder ,getting parts that are off size:

Spoke too soon sizing is still off.

How much is sizing off? If it's a small amount and uniform across the bed, use M579 to correct it.